Method and system for decomposing and activating manganese carbonate at low temperature

A technology of manganese carbonate ore and manganese carbonate ore, which is applied in the field of low-temperature decomposition and activation of manganese carbonate, can solve the problems of waste of coal resources and high cost, and achieve the effects of optimizing the process, reducing manpower and material costs, and shortening the liquid production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

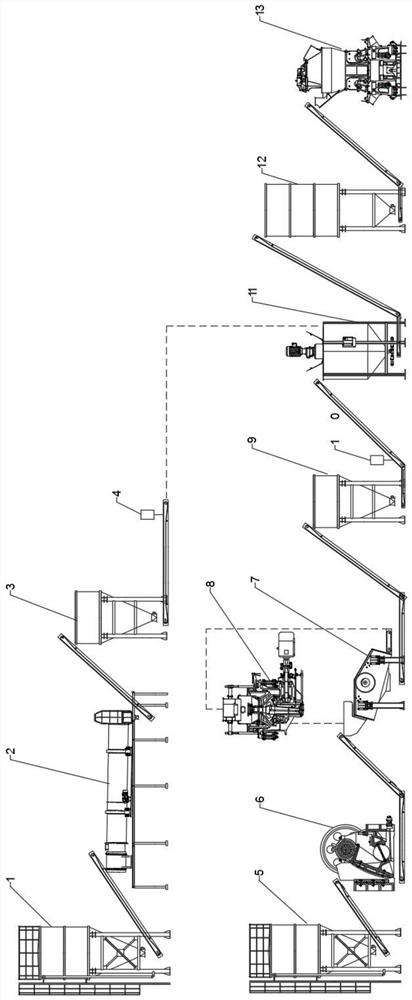

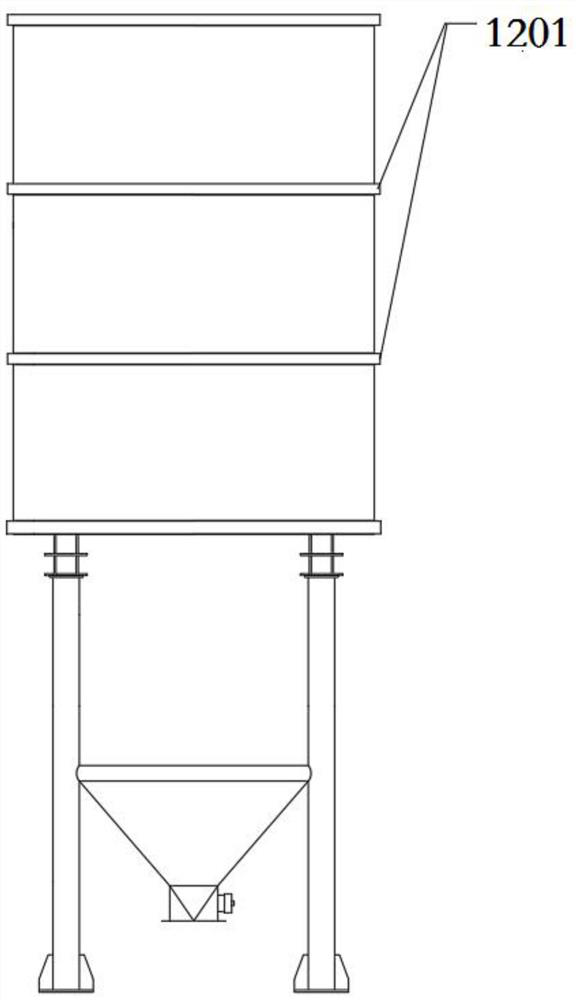

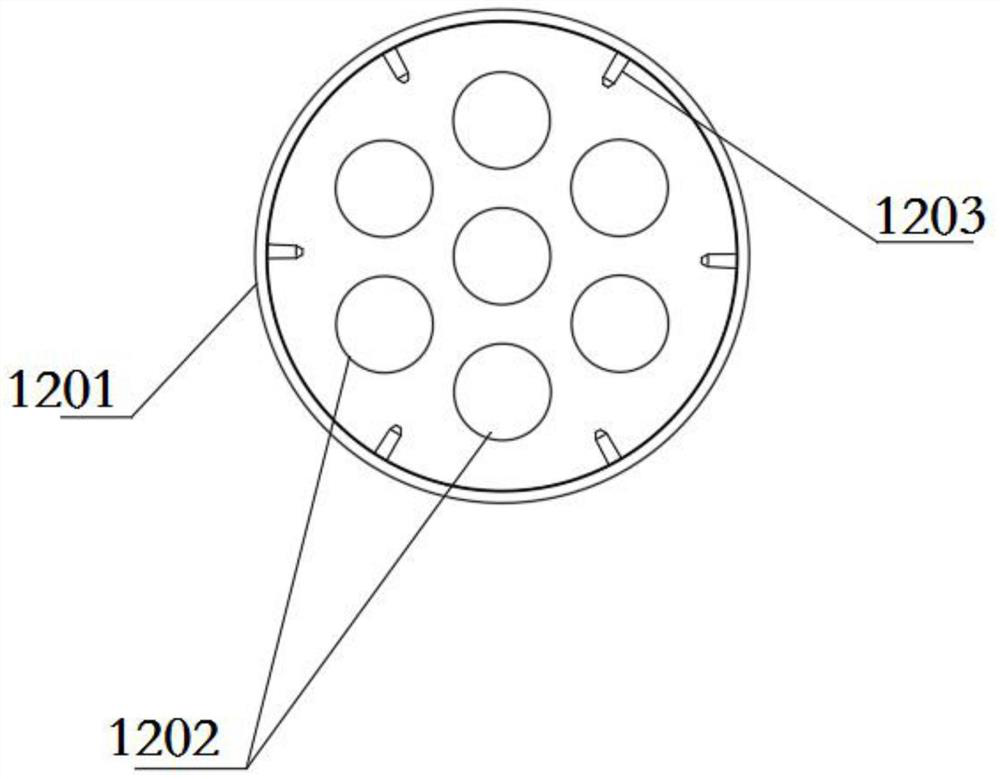

[0018] In order to provide a low-temperature decomposition and activation solution for improving the grade of manganese carbonate and manganese and reducing the cost of using manganese dioxide to prepare roasted powder, the preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings.

[0019] A method for low-temperature decomposition and activation of manganese carbonate, specifically comprising the steps of:

[0020] Crush the manganese carbonate ore until the particle size is less than 10mm, blend according to the ratio of 100 parts of manganese carbonate ore and 3 to 5 parts of finely washed coal, and send the blended mixture to the inner cavity of the reduction tank. The inner cavity roasts the mixture at a low temperature, the roasting temperature is controlled at 850°C to 940°C, and the roasting time is 18h to 24h; after the roasting is completed, manganese monoxide is generated, and its manganese grade is 6% highe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com