Novel method for preferentially extracting and separating praseodymium neodymium rare earth and recovering trace cobalt elements from low-concentration magnetic material waste acid dissolution mother liquor

A low-concentration, new-method technology, applied in the field of rare earth separation, to reduce production costs, reduce residual acid, and facilitate waste water treatment and clean production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

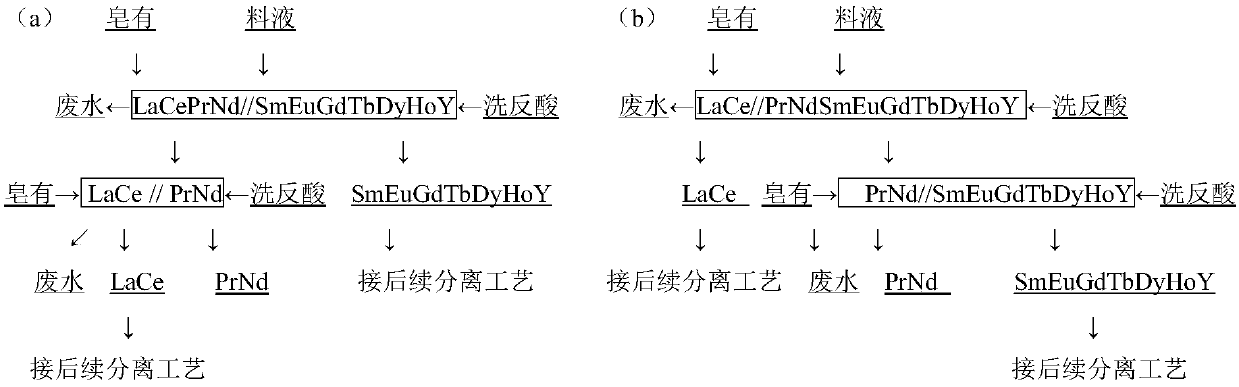

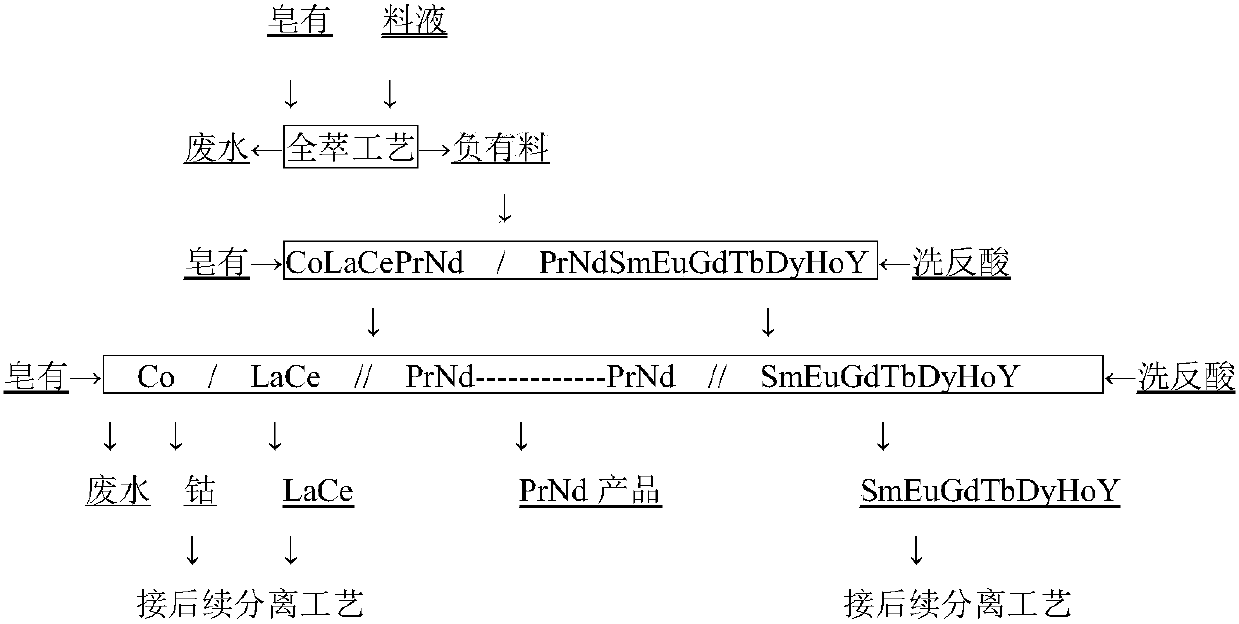

Method used

Image

Examples

Embodiment 1

[0041] The present invention: a new method for preferentially extracting and separating praseodymium neodymium rare earths and recovering trace cobalt elements from low-concentration magnetic material waste acid-soluble mother liquor, comprising the following steps:

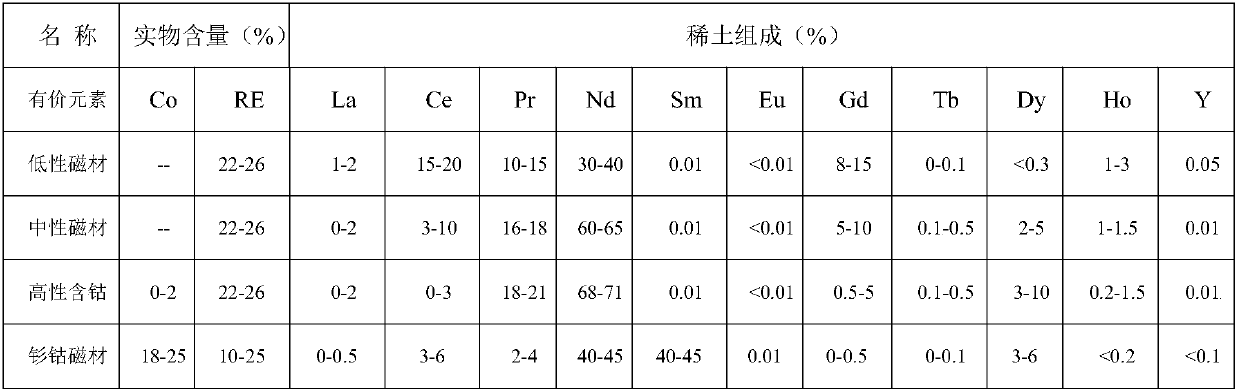

[0042] In step (1), the mass ratio of the refractory component to the easy-to-extract component is 1.5:8.5. Rare earth concentration of feed liquid: 0.5mol / L, pH=3.0.

[0043] In step (2), the organic extractant is composed of di(2-ethylhexyl) 2-ethylhexyl phosphoric acid (P507) acidic phosphorus extractant and sulfonated kerosene. Extractant (P507) concentration is 1.50mol / L, adopts the liquid alkali continuous saponification of 5.5mol / L, saponification value is 0.54mol / L. The washing back acid is hydrochloric acid.

[0044] A factory uses various rare earth magnetic material wastes as raw materials, and the concentration and distribution of the rare earth material liquid obtained by mixing and roasting in pro...

Embodiment 2

[0057] The present invention: a new method for preferentially extracting and separating praseodymium neodymium rare earths and recovering trace cobalt elements from low-concentration magnetic material waste acid-soluble mother liquor, comprising the following steps:

[0058] In step (1), the mass ratio of the refractory component to the easy-to-extract component is 2.5:7.5. Rare earth concentration of feed liquid: 0.36mol / L, pH=3.0.

[0059] In step (2), the organic extractant is composed of di(2-ethylhexyl) 2-ethylhexyl phosphoric acid (P507) acidic phosphorus extractant and sulfonated kerosene. The concentration of extractant (P507) is 1.50mol / L, and the calcium hydroxide aqueous emulsion of about 3.0mol / L is used for continuous calcium saponification, and the saponification value is about 0.50±0.01mol / L. The washing back acid is hydrochloric acid.

[0060] A factory uses various rare earth magnetic material wastes as raw materials, and the concentration and distribution o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com