Composite explosion container

An explosion container and composite technology, applied in the field of containers, can solve the problems of inability to observe the explosion process accurately, meet the requirements of explosion welding, construction and pedestrian impact, etc., and achieve the goal of ensuring anti-explosion performance, reducing vibration and noise, and reducing damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

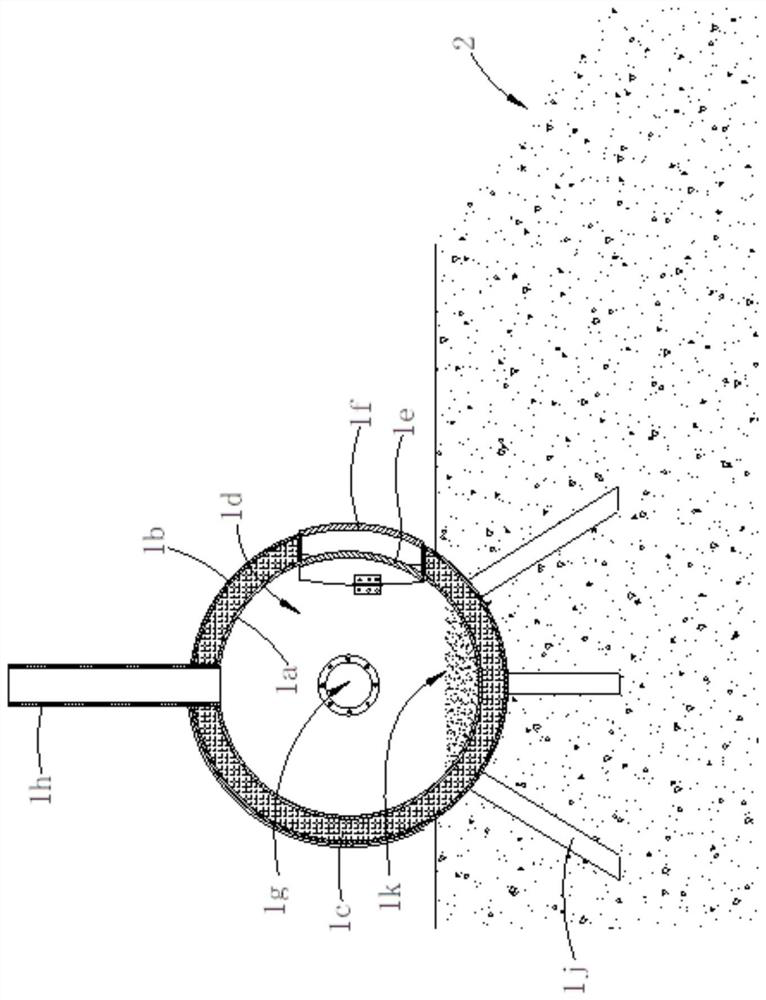

[0027] Such as figure 1 shown

[0028] The composite explosion vessel includes a vessel body and a shock-absorbing foundation 2 .

[0029] The container body includes a container inner wall 1a, a buffer interlayer 1c and an outer wall 1b of the container. The buffer interlayer 1c is arranged between the inner wall 1a of the container and the outer wall 1b of the container. The material of the inner wall 1a of the container is 16MnR steel or other high-strength steel, and the wall thickness is 20-50mm. The outer wall 1b of the container is made of carbon steel or other low-alloy steel, and the wall thickness is 10-15mm. The inner space of the inner wall 1a of the container is an explosion chamber 1d, and the buffer interlayer 1c is filled with expanded vermiculite (the buffer interlayer 1c is filled with foamed plastic or Aluminum foam can achieve similar effects);

[0030] A particle layer 1k is laid on the bottom of the explosion chamber 1d, and the particle layer 1k is qua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com