Grating structure

A grating structure and grating technology, applied in diffraction gratings, optics, optical components, etc., can solve the problems of different dispersion capabilities, and achieve the effect of reducing the difficulty of process manufacturing, high extinction ratio and high efficiency polarization beam splitting function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

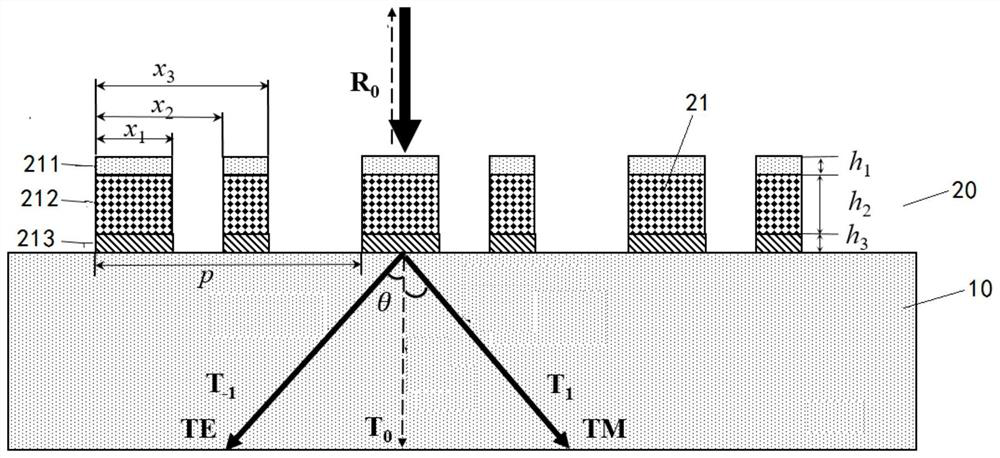

[0051] Such as figure 1 As shown, in this embodiment, the grating ridge 21 has a three-layer structure.

[0052] It should be noted that the wavelength is related to the parameters of the grating structure (according to the strict coupled wave theory, if the influence of the material refractive index change is not considered, the same diffraction efficiency value can be obtained by scaling the grating structure in proportion to the incident center wavelength) , such as when the incident center wavelength increases or decreases, the period of the grating structure and the depth of each layer also increase or decrease in proportion. But in reality, due to the influence of the material dispersion relationship on the different refractive indices corresponding to different wavelengths, the ratio of each parameter increase or decrease will be adjusted, but through proper optimization, more suitable grating parameters can also be found. Due to the difference in the optimization algor...

Embodiment 2

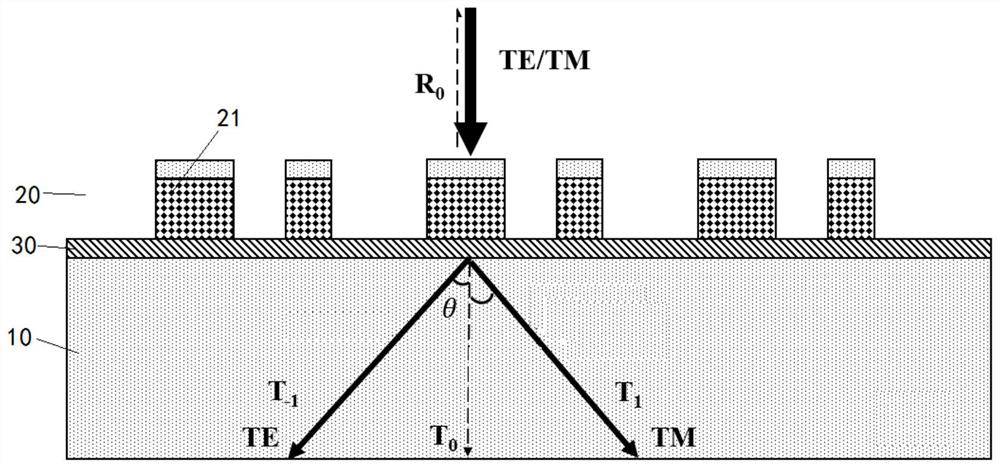

[0073] Such as figure 2 As shown, in this embodiment, the grating ridge 21 has two layers, and in this embodiment, there is a cut-off layer 30 between the grating layer 20 and the base structure 10, and the cut-off layer 30 may be a residual glue layer in the imprinting process , can also be a layer made separately. In this embodiment, the refractive index of the cut-off layer 30 is smaller than that of the layer connected to the cut-off layer 30 in the grating ridge 21 , and the refractive index of the cut-off layer 30 is greater than that of the base structure 10 . And the one of the two layers farther from the cut-off layer 30 has a smaller refractive index than the other layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com