Factory digitization design method based on BIM technology

A design method and plant technology, applied in the direction of design optimization/simulation, calculation, manufacturing calculation system, etc., can solve the problems of cumbersome design process, deviation, and inability to meet the needs of digital and intelligent operation and maintenance of the cement industry, and achieve convenient data Information management, improving procurement efficiency, and realizing the effect of real-time tracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

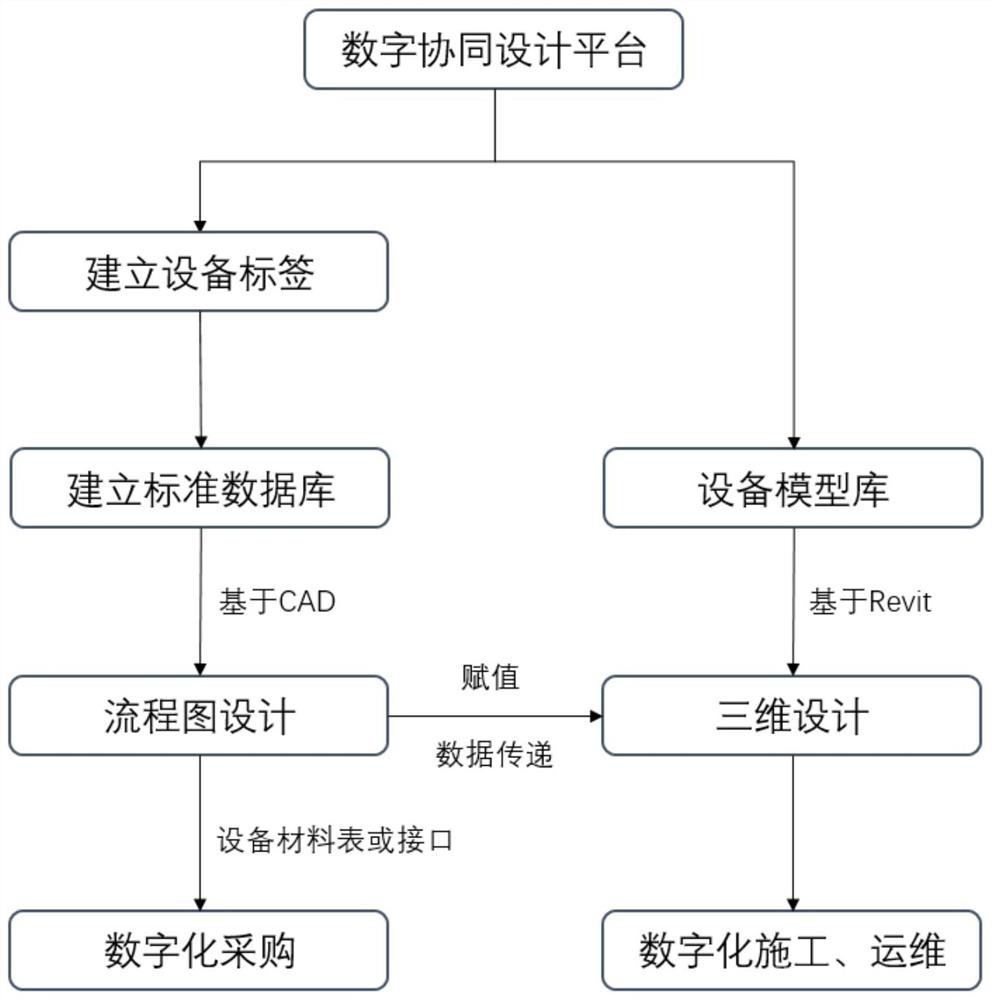

[0034] Such as figure 1 As shown, a kind of design method of factory digitalization based on BIM technology described in the present invention, comprises the following steps:

[0035] (1) Establish labels for each professional equipment;

[0036] (1.1) Configure the same labels for 2D legends, 3D models, and design attributes;

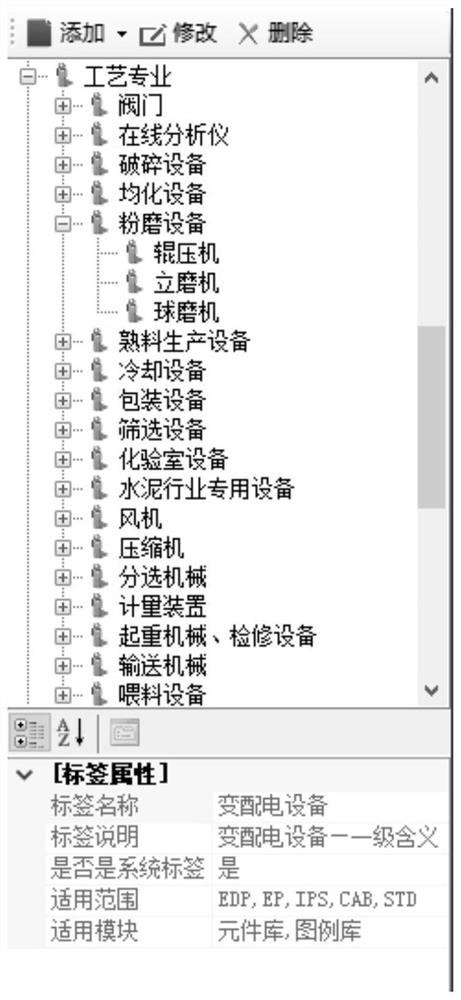

[0037] (1.2) The label of the equipment is entered according to the tree structure of specialty-equipment type-equipment name;

[0038] (2) Establish a standard database;

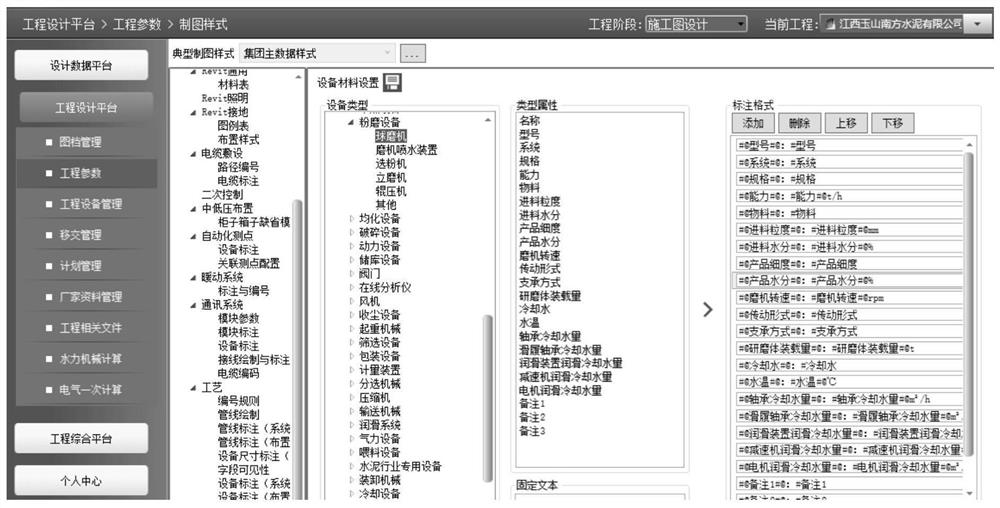

[0039] (2.1) Enter the corresponding equipment information according to the tree structure of specialty, equipment type, and equipment name, including but not limited to equipment name, equipment code, equipment attributes, and parameter units;

[0040] (2.2) Add design attributes according to project requirements;

[0041] (3) Digital design; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com