Preparation method of polyanion anti-shrinkage fruit fresh-keeping coating liquid

A polyanionic, anti-shrinkage technology, applied in the preservation of food ingredients as anti-microbial, protection of fruits/vegetables with protective coating, sustainable manufacturing/processing, etc. Good barrier properties, low cost, anti-aging and spoilage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

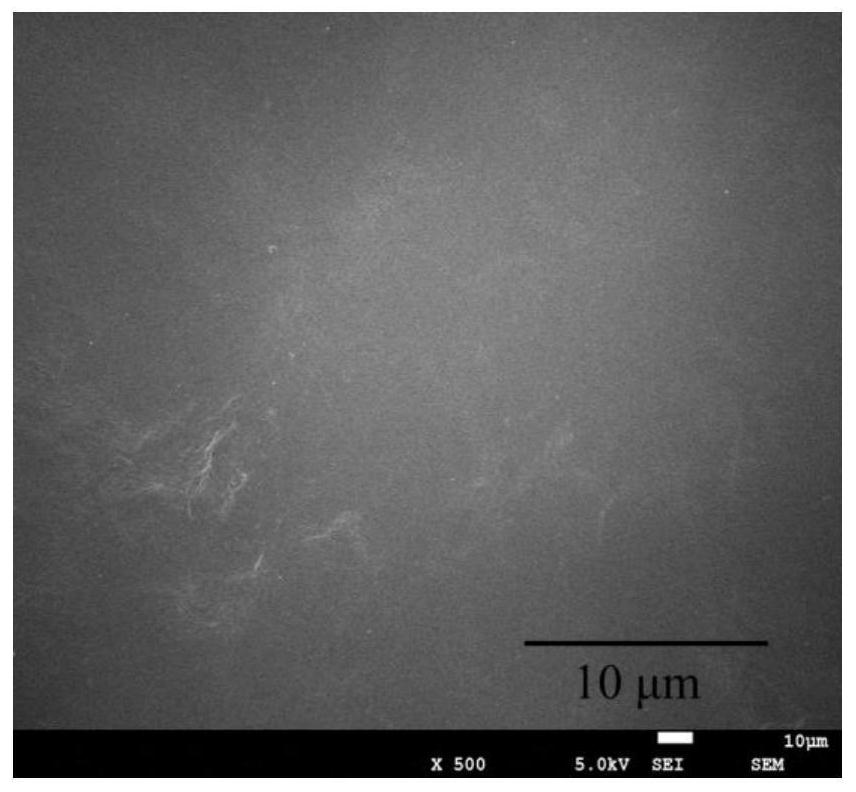

Image

Examples

Embodiment 1

[0042] Embodiment 1: The preparation method of the polyanionic anti-shrinkage fruit fresh-keeping coating solution of the present embodiment is carried out according to the following steps:

[0043] 1. Weigh 7g sodium carboxymethyl starch (CMS) and 3g carrageenan, 0.3g carboxylated cellulose nano whiskers (C-CNC), 4g glycerin and 400mL distilled water;

[0044] 2. Add sodium carboxymethyl starch and carrageenan to 200 mL of distilled water, and stir evenly to obtain a mixture of sodium carboxymethyl starch and carrageenan;

[0045] 3. Add carboxylated cellulose nano-whiskers to the remaining 200mL of distilled water, and after processing with an ultrasonic cell pulverizer, obtain a carboxylated cellulose nano-whiskers dispersion;

[0046] Four, the mixed solution of sodium carboxymethyl starch and carrageenan is mixed with the carboxylated cellulose nano-whisker dispersion, mechanically stirred at a speed of 400rmp in a constant temperature water bath at 75°C for 90min, then a...

Embodiment 2

[0047]Embodiment 2: The difference between this embodiment and Example 1 is that the carboxylated cellulose nano-whiskers of 0.6g are weighed in the step 1, and others are the same as in Example 1, and the polyanion anti-shrinkage fruit fresh-keeping coating solution obtained is denoted as CCC 6 .

Embodiment 3

[0048] Embodiment 3: The present embodiment differs from Example 1 in that the carboxylated cellulose nano-whiskers of 0.9g are weighed in step one, and others are the same as in Example 1. CCC 9 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com