Oil-water separation device and separation method based on PTFE hollow fiber membrane

A technology of oil-water separation device and fiber membrane, which is applied in the direction of separation method, grease/oily substance/floating matter removal device, liquid separation, etc. It can solve the problems of limited application range, long-term dispersion, and agglomeration easily caused by standing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

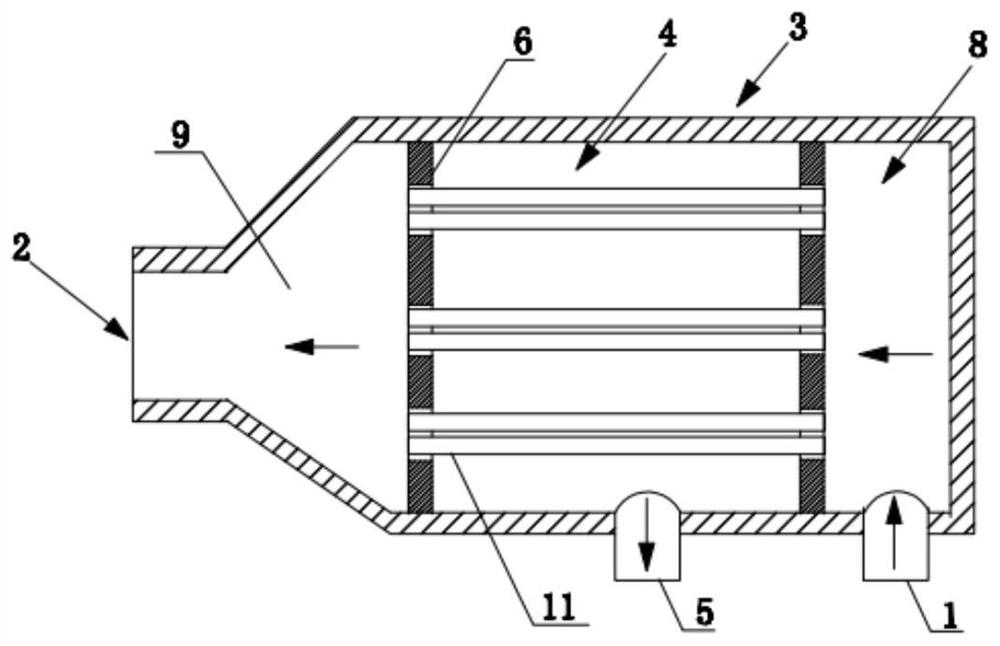

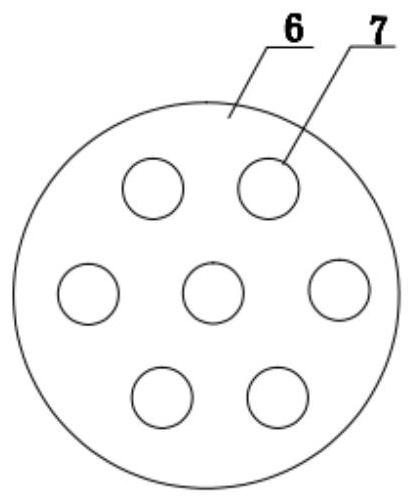

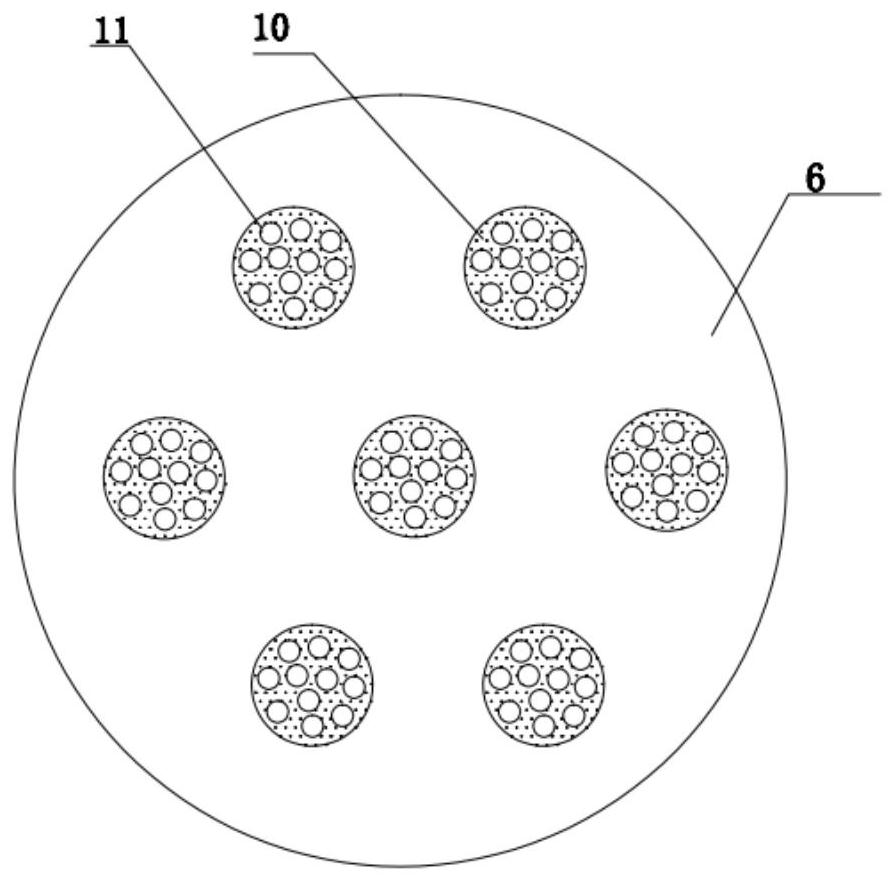

[0061] As shown in the figure, an oil-water separation device based on PTFE hollow fiber membranes includes a filter housing 3 with an oil-water mixture inlet 1 and a water outlet 2, a filter chamber 8 is arranged inside, and a filter chamber connected to the filter chamber 8 is also included. The oil outlet chamber 5 for discharging the filtered oil, the oil-water mixture inlet 1 and the water outlet 2 are connected with the filter chamber 8, and the filter chamber 8 is provided with a filter chamber 8 divided into a filter treatment area 4 and a The orifice 6 of the storage area 9 for storing filtered water is provided with installation holes 7 for fixing the modified PTFE hollow fiber membrane filtration system on the two orifice plates 6, and the modified PTFE hollow fiber membrane filtration system is fixed on two Between the orifice plates 6; the inlet of the modified PTFE hollow fiber membrane filtration system is connected to the inlet of the oil-water mixture, the outl...

Embodiment 2

[0069] The same parts of this embodiment as in Embodiment 1 will not be repeated, and the difference is that at least one secondary oil-water separation device is further included, and the adjacent secondary oil-water separation devices are connected to each other. At this time, the connecting part of the adjacent secondary oil-water separation device can be used as the inlet of the oil-water mixture, and the oil-water mixture is separated and filtered for multiple times to achieve the effect of multiple separation and filtration.

[0070] Stretching is a key step in the preparation of PTFE hollow fiber membranes. During the stretching process, the morphology of PTFE hollow fiber membranes changes significantly. At lower stretching ratios, microcracks first form on the surface of PTFE hollow fiber membranes. With the increase of the multiple, the microcracks further expand to form continuous irregular areas. Kitamura et al. refer to the solid aggregates of particles as "nodes"...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water flux | aaaaa | aaaaa |

| Water flux | aaaaa | aaaaa |

| Water flux | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com