Preparation process of warm-keeping and flame-retardant fabric

A flame-retardant fabric and preparation process technology, which can be used in the manufacture of fire-retardant and flame-retardant filaments, dyeing methods, single-component polyester rayon, etc., and can solve problems such as not meeting the needs of the market.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

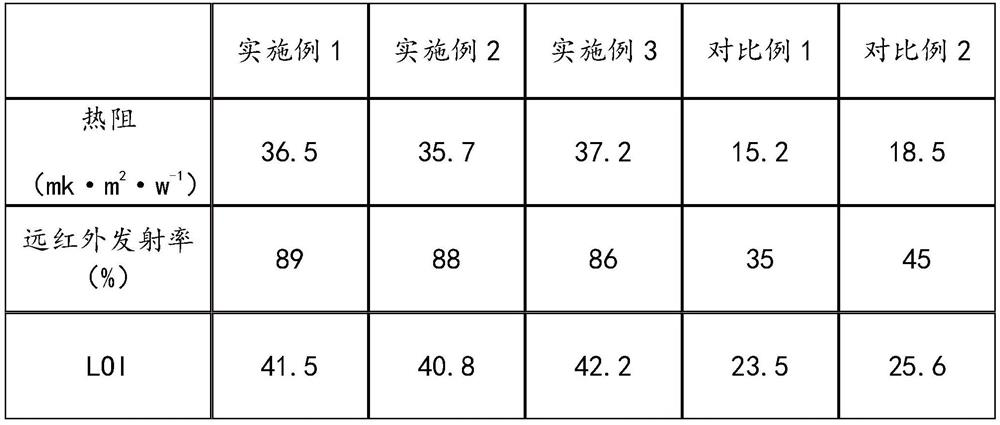

Examples

Embodiment 1

[0032] A kind of preparation technology of heat-retaining flame-retardant fabric, comprises the following steps:

[0033] Step A1, weaving process: Weaving cotton, viscose fiber, and modified polylactic acid fiber on a machine to obtain a fabric blank;

[0034] Step A2, dyeing treatment: put the fabric blank prepared in step A1 into the dye vat, add dye, soak and dye at 80°C for 30 minutes, then put the fabric into the dye vat without dye, add antistatic agent and softener, and dry it at 50°C Soak for 30 minutes, dry, and make the semi-finished fabric;

[0035] Step A3, soaping: Soap the semi-finished fabric prepared in step A2 with a soaping agent, then hot wash and cold wash, until the floating color of the dye is washed, and then fix the color, and then dry and shape it through a setting machine Treated to produce thermal insulation and flame retardant fabrics.

[0036] Wherein, the weight parts of cotton, viscose fiber and modified polylactic acid fiber described in step...

Embodiment 2

[0054] A kind of preparation technology of heat-retaining flame-retardant fabric, comprises the following steps:

[0055] Step A1, weaving process: Weaving cotton, viscose fiber, and modified polylactic acid fiber on a machine to obtain a fabric blank;

[0056] Step A2, dyeing treatment: put the fabric blank prepared in step A1 into the dye vat, add dye, soak and dye at 85°C for 50 minutes, then put the fabric into the dye vat without dye, add antistatic agent and softener, and dry it at 55°C Soak for 40min, dry, and make the fabric semi-finished product;

[0057] Step A3, soaping: Soap the semi-finished fabric prepared in step A2 with a soaping agent, then hot wash and cold wash, until the floating color of the dye is washed, and then fix the color, and then dry and shape it through a setting machine Treated to produce thermal insulation and flame retardant fabrics.

[0058] Wherein, the weight parts of cotton, viscose fiber and modified polylactic acid fiber described in s...

Embodiment 3

[0076] A kind of preparation technology of heat-retaining flame-retardant fabric, comprises the following steps:

[0077] Step A1, weaving process: Weaving cotton, viscose fiber, and modified polylactic acid fiber on a machine to obtain a fabric blank;

[0078] Step A2, dyeing treatment: put the fabric blank prepared in step A1 into the dye vat, add dye, soak and dye at 88°C for 60 minutes, then put the fabric into the dye vat without dye, add antistatic agent and softener, and dry it at 58°C Soak for 45 minutes, dry, and make the fabric semi-finished product;

[0079]Step A3, soaping: Soap the semi-finished fabric prepared in step A2 with a soaping agent, then hot wash and cold wash, until the floating color of the dye is washed, and then fix the color, and then dry and shape it through a setting machine Treated to produce thermal insulation and flame retardant fabrics.

[0080] Wherein, the weight parts of cotton, viscose fiber and modified polylactic acid fiber described ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com