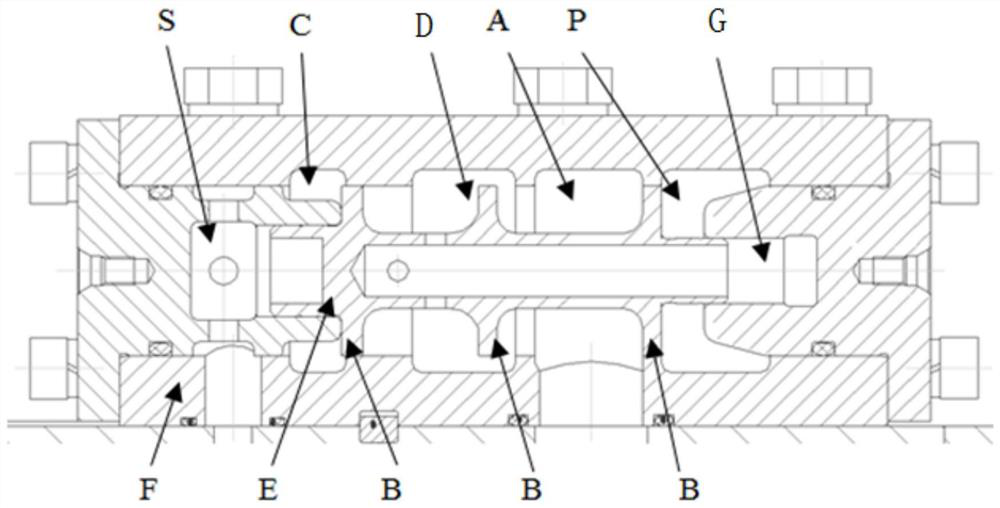

Signal oil output structure of impact cylinder of hydraulic rock drill

A technology of hydraulic rock drill and output structure, applied in the direction of impact drilling, reciprocating drilling rig, drilling equipment, etc., can solve problems such as design and processing difficulties, reduce processing difficulty, prolong cylinder life and service interval, and improve product quality. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with specific preferred embodiments, but the protection scope of the present invention is not limited thereby.

[0031] For the convenience of description, the relative positional relationship of each component, such as: the description of up, down, left, right, etc., is described according to the layout direction of the drawings in the specification, and does not limit the structure of this patent.

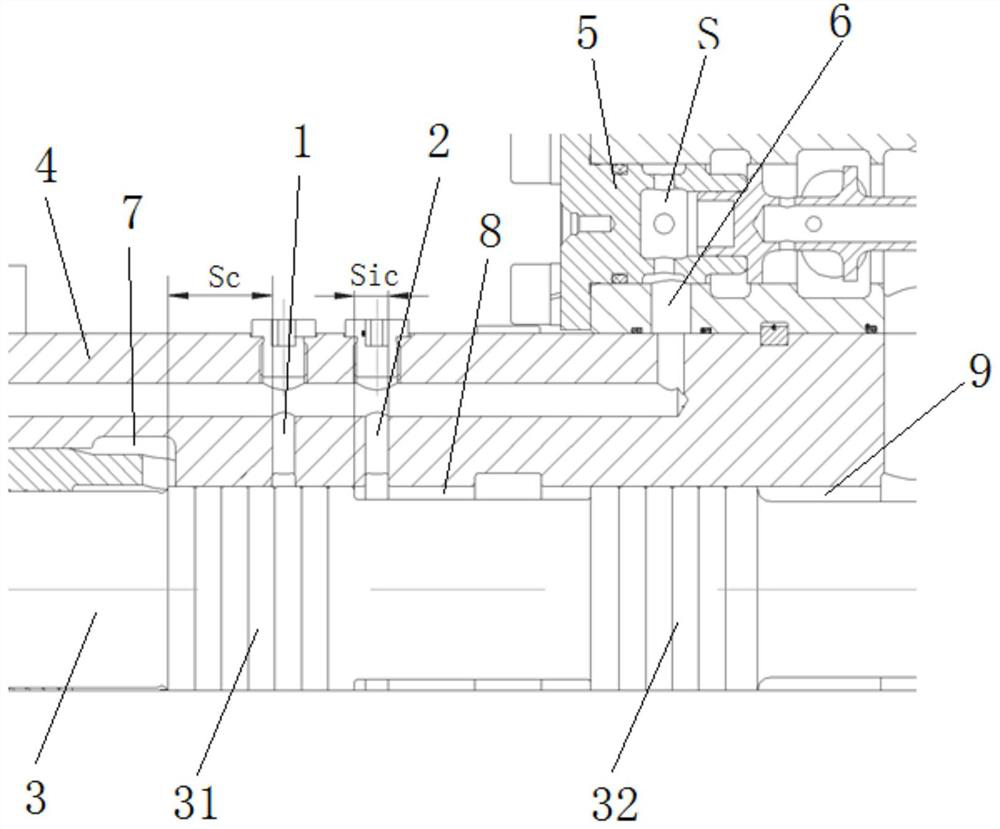

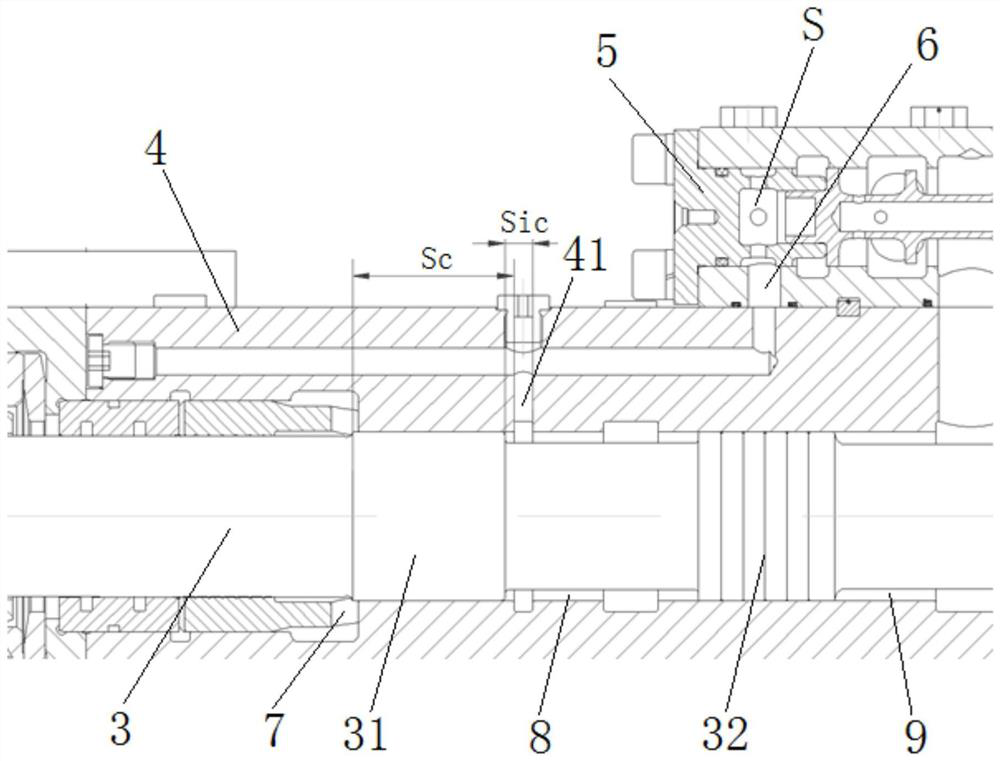

[0032] Such as image 3 As shown, the first embodiment of the signal oil output structure of the impact cylinder of the hydraulic rock drill of the present invention includes an impact cylinder and a reversing valve 5 , and the impact cylinder includes an impact cylinder 4 and an impact piston 3 .

[0033] One end of the impact piston 3 is installed in the impact cylinder 4, and the impact piston 3 is provided with a first annular boss 31 and a second annular boss 32 that are matched with the inner cavity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com