Superconducting magnetic suspension bearing mechanism

A magnetic suspension bearing and superconducting technology, applied in the direction of bearings, shafts and bearings, mechanical equipment, etc., can solve the problems of high cost and complex structure, and achieve the effects of high uniformity, large movable space and high self-stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

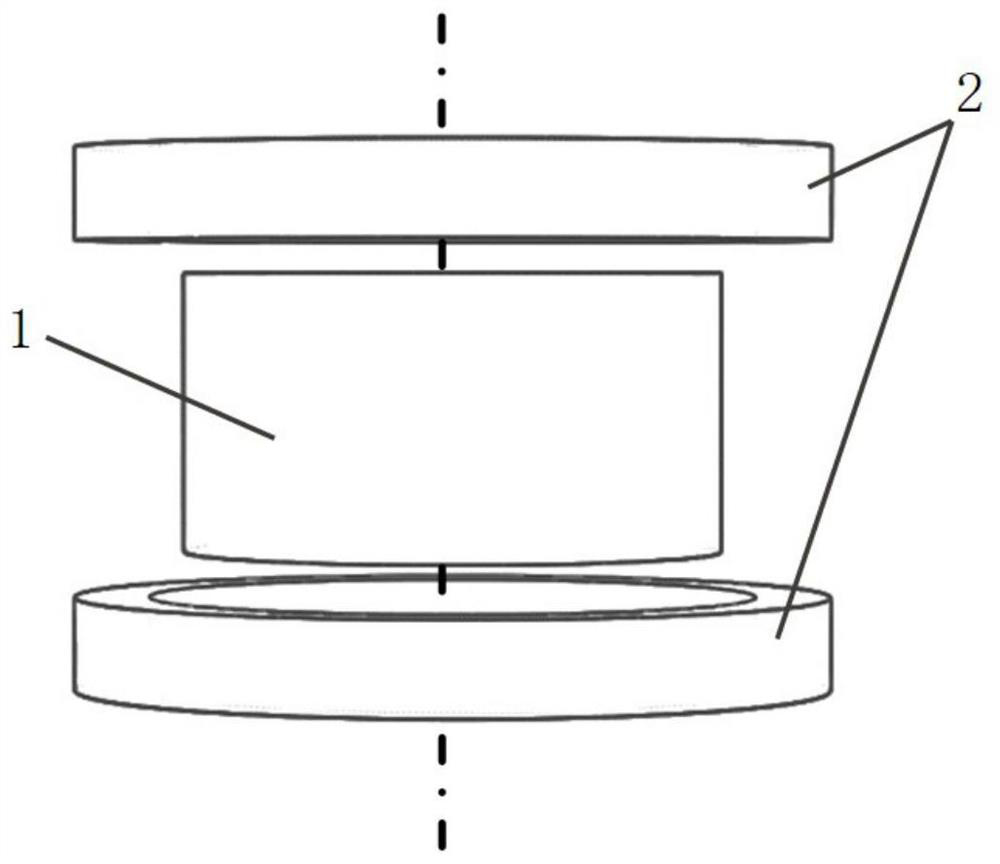

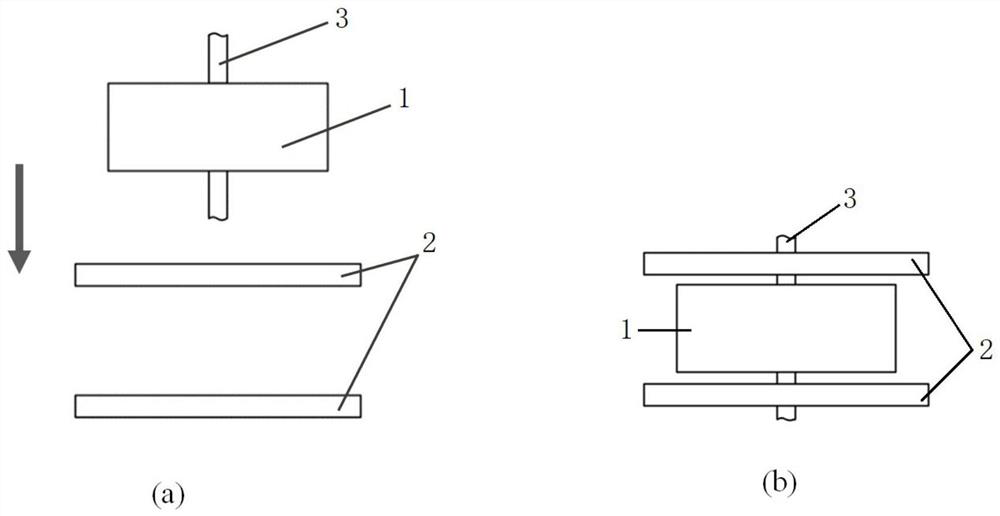

[0037] This embodiment provides a vertical superconducting magnetic suspension bearing mechanism, the schematic diagram is as follows figure 2 shown. The mechanism includes: a permanent magnet 1 , a superconducting closed winding 2 and a main shaft 3 .

[0038]The connection relationship and functions among the above components are as follows: the permanent magnet 1 and the superconducting closed winding 2 are arranged coaxially. The superconducting closed winding 2 adopts a jointless superconducting coil, which is symmetrically placed on the upper and lower ends of the permanent magnet 1 relative to the permanent magnet 1 and rigidly fixed on the suspension system bracket respectively. The geometric center distance between the two jointless superconducting coils is equal to 1.5 times the sum of the height of the permanent magnet 1 and the height of a single jointless superconducting coil. The jointless superconducting coil at the upper end of the permanent magnet 1 is used...

Embodiment 2

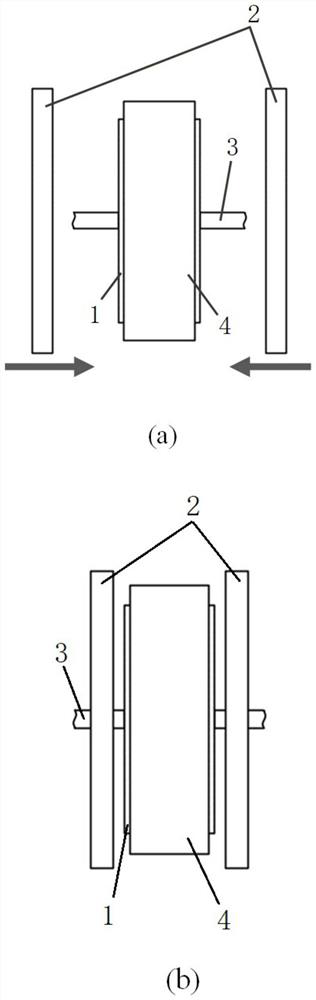

[0042] This embodiment provides a horizontal five-degree-of-freedom superconducting magnetic suspension bearing mechanism, the schematic diagram is as follows image 3 shown. The mechanism includes: a permanent magnet 1 , a superconducting closed winding 2 , a main shaft 3 and a permanent magnet ring 4 .

[0043] The connection relationship and functions among the above components are as follows: the permanent magnet 1 and the superconducting closed winding 2 are arranged coaxially. The superconducting closed winding 2 adopts a jointless superconducting coil, which is symmetrically placed on the left and right sides of the permanent magnet 1 relative to the permanent magnet 1, and can be controlled to move along the axis according to requirements. The jointless superconducting coil on the left side of the permanent magnet 1 is used to provide the permanent magnet 1 with a force to the right along the axis, and the jointless superconducting coil on the right side of the perman...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com