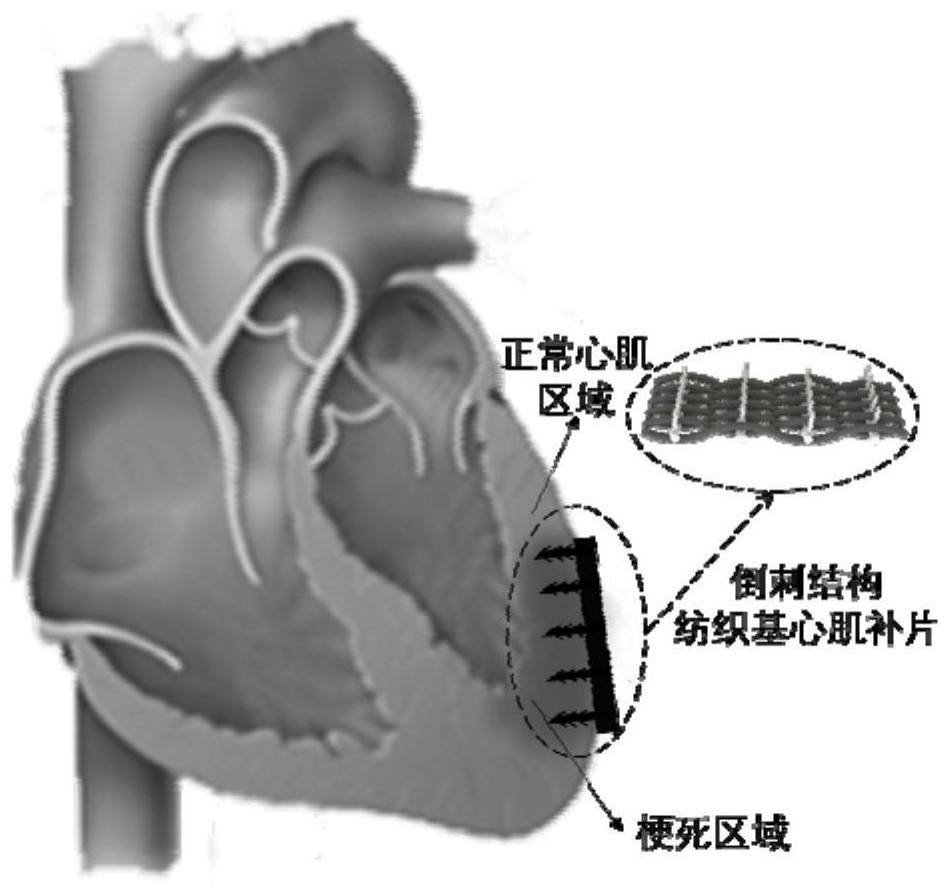

Suture-free three-dimensional textile-based conductive myocardial patch and preparation method thereof

A textile-based, myocardial technology, applied in medical science, prosthesis, etc., can solve the problems of complex suture of myocardial patch, and achieve the effect of reducing postoperative complications, improving myocardial repair effect, and reducing the difficulty of surgery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A preparation method of a suture-free three-dimensional textile-based conductive myocardial patch, specifically as follows:

[0032] (1) prepare barbed short wire;

[0033] (1.1) Write a barbed short-line printing program;

[0034] Among them, the length of the short line is 2 mm, the diameter is 10 μm, one end of the short line is a beveled needle-point shape, and the other end is a plane; the angle between the beveled needle-pointed slope and the short line in the axial direction is 60°; the cross-sectional shape of the barb is circular; The barbs are located on the peripheral surface of the short line; the distance between adjacent barbs on the short line of the barb is 0.1mm, and the angle between the barb and the short line (trunk axis) is 60°; all the barbs are facing the end where the plane of the short line is located ; Along the axial direction of the short line, the barbs are distributed in rows, the number of barb rows is 1 row, and the angle between two adj...

Embodiment 2

[0043] A preparation method of a suture-free three-dimensional textile-based conductive myocardial patch, specifically as follows:

[0044] (1) prepare barbed short wire;

[0045] (1.1) The existing commercial polycaprolactone barbed suture is used as raw material; wherein, the diameter of the barbed suture is 26 μm; the cross-sectional shape of the barb is triangular; the barb is located at the center of the barbed suture (trunk axis) On the peripheral surface, and evenly arranged along a single direction; the distance between adjacent barbs of the barbed suture (trunk axis) is 0.2mm, and the angle between the barbs and the barb suture (trunk axis) is 60°;

[0046] (1.2) Cut the barbed suture into short lines with a length of 3mm; the two ends of the short lines are flat; along the axial direction of the short line, the barbs are distributed in rows, the number of barb rows is 2 rows, and two adjacent rows are inverted The angles between spines are equal;

[0047] (1.3) Cut...

Embodiment 3

[0055] A preparation method of a suture-free three-dimensional textile-based conductive myocardial patch, specifically as follows:

[0056] (1) prepare barbed short wire;

[0057] After the molten polypropylene solution is poured into the barbed stub mold, it is solidified and formed. Among them, the length of the short line is 3 mm, and the diameter is 35 μm; one end of the short line is a beveled needle-point shape, and the other end is a plane; the angle between the beveled needle-pointed slope and the short line is 10°; The thorns are located on the peripheral surface of the short line; the distance between adjacent barbs on the short line of the barb is 0.3mm, and the angle between the barb and the short line (trunk axis) is 10°; all the barbs are facing the end where the plane of the short line is located; Along the axial direction of the short line, barbs are distributed in rows, the number of barb rows is 3 rows, and the angle between two adjacent rows of barbs is equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com