Processing method of baphicacanthus cusia/ polygonum tinctorium/ isatis indigotica stem/leaf processed substances

A technology of Indigo Naturalis and filtrate, applied in the processing field of Indigo Naturalis, can solve problems such as increasing sewage treatment costs, and achieve the effects of reducing treatment costs, reducing impact, and reducing total ash content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

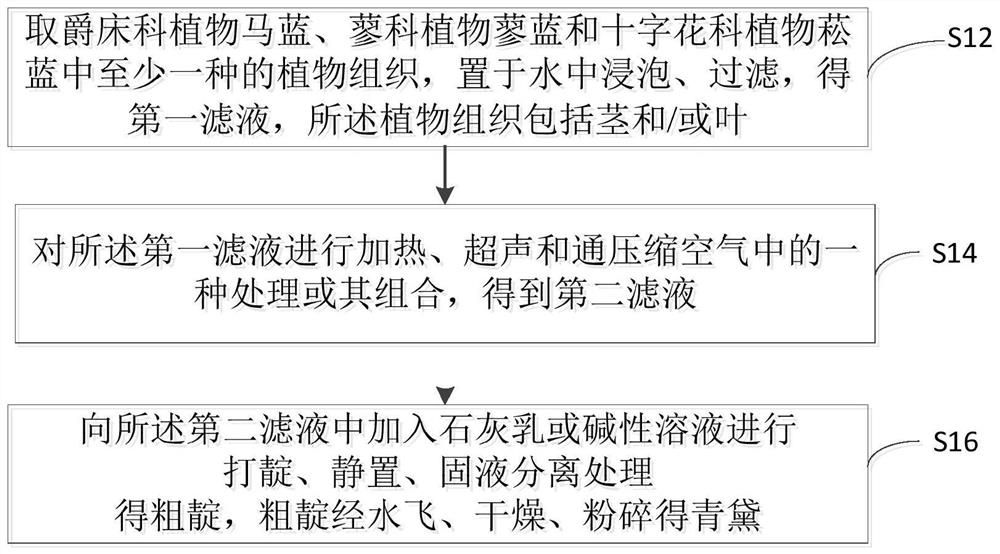

Method used

Image

Examples

Embodiment 1

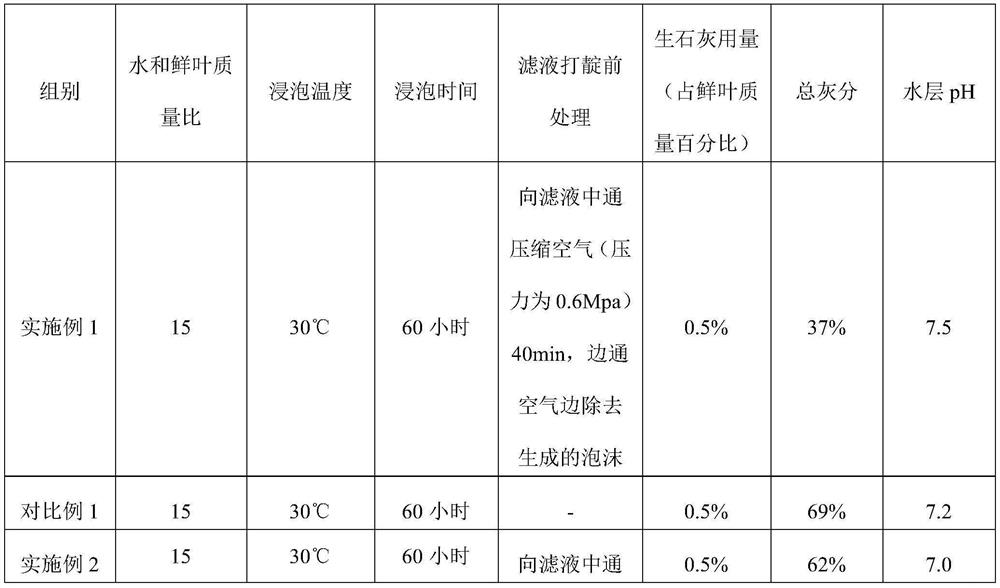

[0060] 1. Take the fresh leaves of the Acanthaceae plant, after being selected and rinsed in a cleaning tank to remove impurities and silt, put them in 30°C water, where the water volume: fresh leaf mass (L: kg) is 15, soak for 60 hours, filter to remove the leaf residue, and obtain the filtrate.

[0061] 2. Pass compressed air (at a pressure of 0.6Mpa) into the filtrate for 40 minutes, and remove the generated foam while passing the air.

[0062] 3. Add milk of lime and stir to beat indigo. The milk of lime is made by adding water with quicklime by conventional methods in the field. The amount of quicklime is 0.5% of the mass of fresh leaves. Leave it to stand and filter to obtain rough indigo. The rough indigo is then sprayed with water and dried at 50°C. , smashed into Qingdai.

Embodiment 2

[0067] 1. Take the fresh leaves of the Acanthaceae plant, after being selected and rinsed in a cleaning tank to remove impurities and silt, put them in 30°C water, where the water volume: fresh leaf mass (L: kg) is 15, soak for 60 hours, filter to remove the leaf residue, and obtain the filtrate.

[0068] 2. Pass compressed air (at a pressure of 0.6Mpa) into the filtrate for 40 minutes without removing the foam.

[0069] 3. Add milk of lime and stir to beat indigo. The milk of lime is made by adding water with quicklime by conventional methods in the field. The amount of quicklime is 0.5% of the mass of fresh leaves. Leave it to stand and filter to obtain rough indigo. The rough indigo is then sprayed with water and dried at 50°C. , smashed into Qingdai.

Embodiment 3

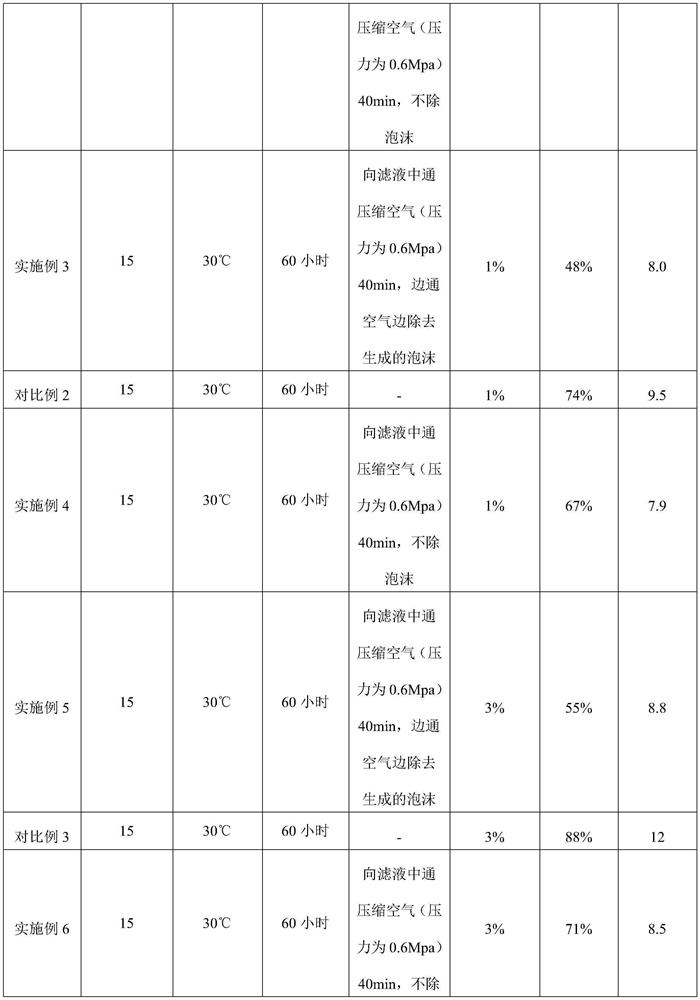

[0071] 1. Take the fresh leaves of the Acanthaceae plant, after being selected and rinsed in a cleaning tank to remove impurities and silt, put them in 30°C water, where the water volume: fresh leaf mass (L: kg) is 15, soak for 60 hours, filter to remove the leaf residue, and obtain the filtrate.

[0072] 2. Pass compressed air (at a pressure of 0.6Mpa) into the filtrate for 40 minutes, and remove the generated foam while passing the air.

[0073] 3. Add lime milk and stir to beat indigo. Lime milk is made by adding quicklime and water using conventional methods in the field. The amount of quicklime is 1.0% of the fresh leaf mass. Leave it to stand and filter to obtain rough indigo. The rough indigo is flown in water and dried at 50°C. , smashed into Qingdai.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com