Dry -particle decorative ceramic tile and preparation method thereof

A technology of ceramic tiles and dry granules, which is applied in the direction of ceramic molding machines and manufacturing tools, can solve problems such as easy reunion and pilling, lower product quality rate, and uneven dry grain surface, so as to achieve stability guarantee and increase the quality rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The present application provides a method for preparing dry grain decorative ceramic tiles, which includes: pre-treating the bricks; applying dry grains, water-retaining wetting agent and glaze slurry to the surface of the bricks after the pretreatment, and post-processing to obtain dry grain decorative ceramic bricks ; Wherein, the water-retaining wetting agent includes transparent protective glaze, suspending agent and water.

[0042] In the prior art, two common preparation techniques are used to prepare dry grain decorated ceramic tiles. For the dry process, in order to reduce the production cost, it is necessary to reduce the amount of dry granules as much as possible, but it is also necessary to ensure the smoothness of the glaze firing, so the particle size of the dry granules is generally controlled between 60 mesh and 160 mesh. Some even reach 200 mesh. After distributing these dry powdered dry particles on the surface of the bricks, another layer of glue must...

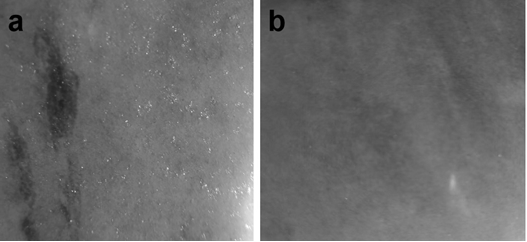

Embodiment 1

[0060] This embodiment provides a kind of dry granular decorative ceramic tile, which is prepared by the following preparation method, including:

[0061] (1) Spread glaze on the surface of the brick, and then use inkjet printing to decorate the pattern;

[0062] (2) Apply a layer of dry granules on the surface of the adobe in step (1) with a dry granule distribution machine, wherein the dry granules include mixed dry granules of crystal flash dry granules and once-fired dry granules, and the application amount is 150g / m 2 , the particle size of crystal flash dry particles is 80 mesh to 150 mesh, and the chemical composition of crystal flash dry particles is based on mass percentage, including ZrO 2 : 6%, SiO 2 : 65%, Al 2 o 3 : 5%, B 2 o 3 : 10%, Na 2 O: 11%, Li 2 O: 3%; the chemical composition of the once-burned dry grain is calculated by weight percentage, including: SiO 2 : 58%, Al 2 o 3 : 10%, CaO: 10%, MgO: 1%, ZnO: 11%, BaO: 1%, K 2 O: 8%, Na 2 O: 1%, of wh...

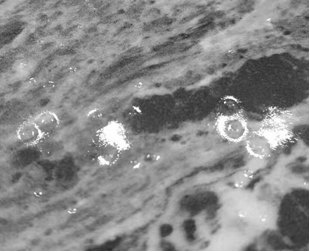

Embodiment 2

[0067] This embodiment provides a kind of dry granular decorative ceramic tile, which is prepared by the following preparation method, including:

[0068] (1) Spread glaze on the surface of the brick, and then use inkjet printing to decorate the pattern;

[0069] (2) Apply a layer of metal dry particles on the surface of the adobe in step (1) with a dry particle distribution machine, wherein the metal dry particles include a mixture of metal copper powder and primary fired dry particles, and the application amount is 200g / m 2 , the metal copper powder accounts for 5% of the total mass of the mixture, and the chemical composition of the once-fired dry particles is calculated by mass percentage, including: SiO 2 : 58%, Al 2 o 3 : 10%, CaO: 10%, MgO: 1%, ZnO: 11%, BaO: 1%, K 2 O: 8%, Na 2 O: 1%;

[0070] (3) Spray water-retaining wetting agent on the surface of the adobe in step (2) with a high-pressure glaze spray cabinet, and the application amount is 130g / m 2 , The water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com