Smelting method for refining inclusions in P91 steel

A smelting method and inclusion technology, which are applied in the field of refining P91 steel inclusions, can solve the problems of large inclusions, large numbers, and low purity, and achieve small inclusions, high safety, and strong operability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

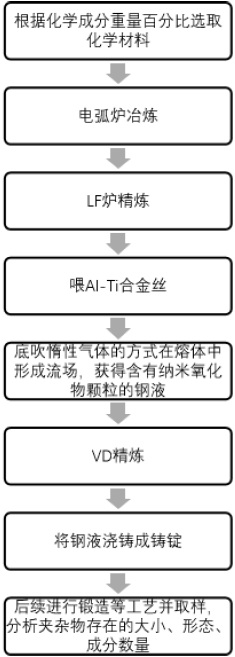

[0027] figure 1A flow chart of smelting fine inclusions according to the present invention is given. The steelmaking production process of the present invention includes: primary smelting in an electric furnace, refining in an LF furnace, feeding aluminum wires, argon blowing at the bottom, VD refining, and casting.

[0028] The chemical material is selected according to the weight percentage of the preset chemical composition. The preset chemical composition weight percentage is: C:0.10wt.%, Si:0.30wt.%, Mn:0.5wt.%, P:0.01wt.%, S:0.005wt.%, V:0.21wt.%, Nb: 0.08wt.%, Ni: 0.30wt.%, Cr: 9.0wt.%, N: 0.04wt.%, Mo: 0.95wt.%, Al: 0.03wt.%, and the balance is Fe. During this process, special personnel are assigned to batch the ingredients, the charging amount of the furnace charge is 53t, and the loading amount of pig iron is 24t. It is believed that the bottom of the furnace is protected by laying steel plates or chips when charging. When there is no residual steel slag in the fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com