Marine gas machine high pressure-stable pressure injection system and control method

A technology of injection system and gas engine, which is applied in the direction of fuel injection control, electrical control, engine control, etc., can solve the problem of difficult to meet the requirements of high dynamic response and C2 emission standards, the inability to realize the precise control of single cylinder gas volume and air-fuel ratio, HC emission concentration is high, to achieve the effect of shortening the injection duration, ensuring injection consistency, and reducing NOX emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

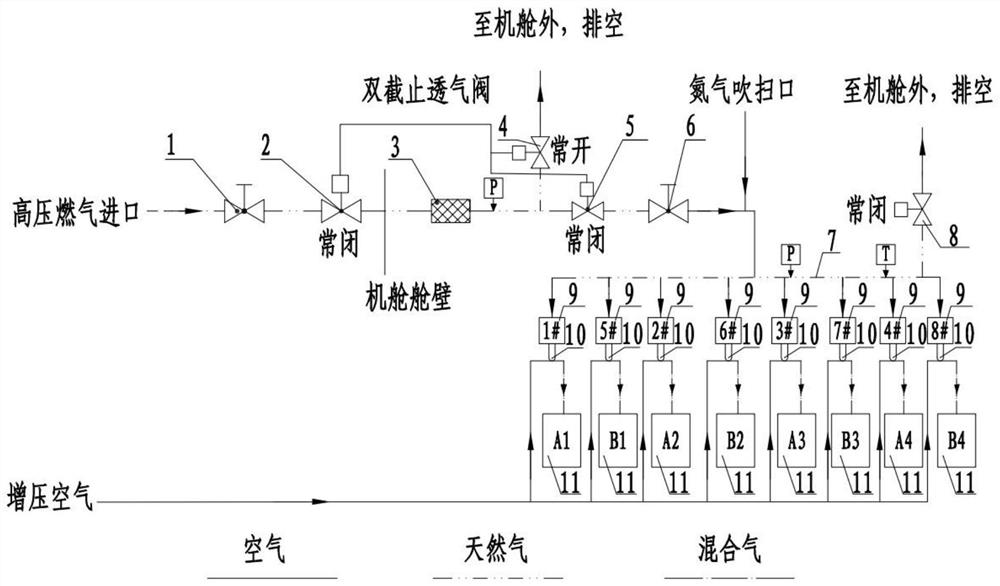

[0029] Such as figure 1 As shown, a kind of marine gas engine high-pressure-stabilized injection system and control method according to the present invention adopts the technical scheme that includes a manual shut-off valve 1, a main gas fuel valve 2, a filter 3, an automatic breather valve 4, Automatic stop valve 5, pressure regulating valve 6, double wall gas rail 7, purge solenoid valve 8, gas injection valve 9, gas nozzle 10, cylinder 11 and supporting pipelines and multiple sensors;

[0030] The manual shut-off valve 1 and the main gas fuel valve 2 are arranged outside the bulkhead of the engine room; the main gas fuel valve 2 and the automatic shut-off valve 5 are normally closed and open when powered, and the automatic vent valve 4 is normally open and powered Closed type; the main gas fuel valve 2, the automatic shut-off valve 5 and the automatic vent valve 4 form a double cut-off breathable valve assembly, and the action of the double cut-off breathable valve assembly...

Embodiment 2

[0039] The difference from Embodiment 1 is that the high-pressure gas behind the pressure regulating valve can be adjusted and matched according to the characteristic requirements of the engine, and the sonic flow of the gas at the outlet of the gas injection valve 9 can be realized under the premise of satisfying the combustion performance. At this time, the gas flow rate and The gas pressure behind the pressure regulating valve 6 is linearly related, which can meet the precise control of the gas injection duration.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com