Method for freeze-drying radix salvia miltiorrhiza

A technology of vacuum freeze-drying and salvia miltiorrhiza, applied in the direction of drying solid materials, drying solid materials without heating, drying, etc., can solve the problems of high labor cost, heavy workload, quality control, etc., to improve the quality of medicinal materials and reduce manpower cost, avoiding the effect of heavy workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

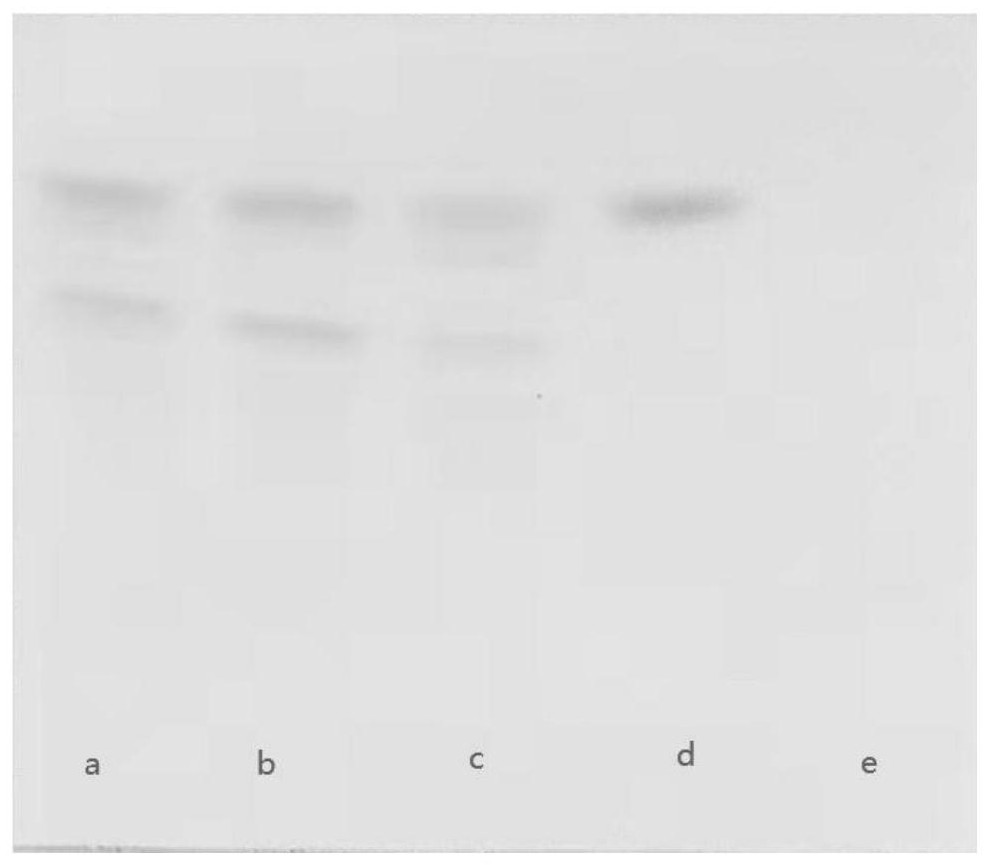

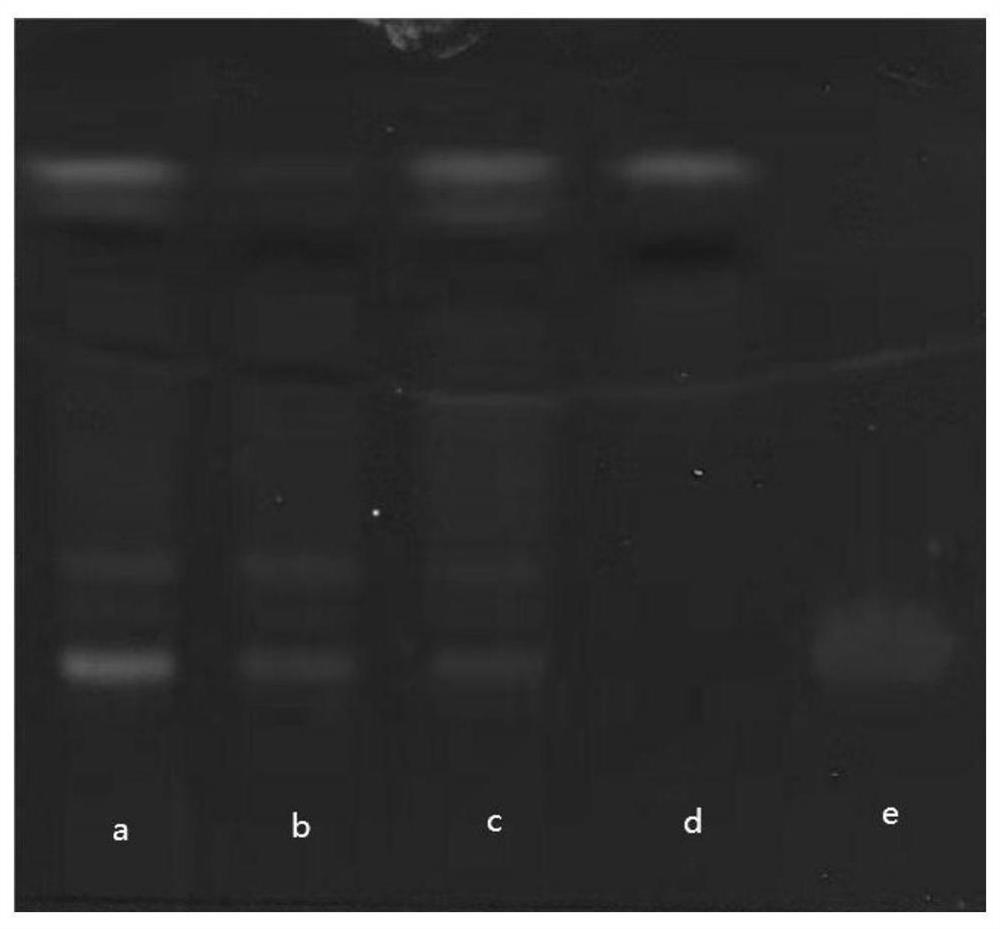

Image

Examples

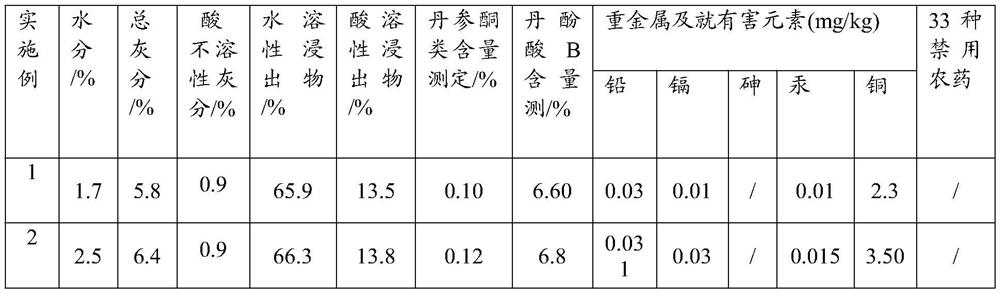

Embodiment 1

[0022] A method for freeze-drying salvia miltiorrhiza, comprising the following steps:

[0023] Remove the soil and fibrous roots of the harvested fresh salvia miltiorrhiza, wash it clean, and slice it with a thickness of about 2.5mm, then place it in a freeze dryer with a stacked thickness of ≤20mm, first pre-freeze at -10°C for 5 hours, and then set the vacuum degree Under the condition in the range of 63-65Pa, control the temperature from -40°C to 45°C for vacuum drying in stages, select the heating rate as 10°C / h, and automatically dry the salvia miltiorrhiza; the specific stage-by-stage temperature and holding time are as follows :

[0024] One stage: -40℃, temperature 3h

[0025] Second stage: -35℃, temperature 2h

[0026] Three stages: -30℃, temperature 2h

[0027] Four stages: -25℃, temperature 3h

[0028] Five stages: -20℃, temperature 2h

[0029] Six sections: -15℃, temperature 3h

[0030] Seven stages: 0℃, temperature 2h

[0031] Eight sections: 5°C, temperat...

Embodiment 2

[0040] A method for freeze-drying salvia miltiorrhiza, comprising the following steps:

[0041] Remove the soil and fibrous roots of the harvested fresh salvia miltiorrhiza, wash it clean, and slice it with a thickness of about 2.5mm, then place it in a freeze dryer with a stacked thickness of ≤20mm, first pre-freeze at -20°C for 5 hours, and then set the vacuum degree Under the condition in the range of 64-70Pa, control the temperature from -40°C to 45°C for vacuum drying in stages, and choose a heating rate of 15°C / h to automatically dry the salvia miltiorrhiza; the specific temperature and duration of staged processing are as follows:

[0042] One stage: -40℃, temperature 3h

[0043] Second stage: -35℃, temperature 2h25min

[0044] Three stages: -30℃, temperature 2h

[0045] Four sections: -25℃, temperature 2h

[0046] Five stages: -20℃, temperature 2h

[0047] Six sections: -15℃, temperature 3h

[0048] Seven stages: 0℃, temperature 2h

[0049] Eight sections: 5°C, t...

Embodiment 3

[0058] A method for freeze-drying salvia miltiorrhiza, comprising the following steps:

[0059] Remove the soil and fibrous roots of the harvested fresh salvia miltiorrhiza, rinse it, slice it into slices with a thickness of about 2.5mm, and place it in a freeze dryer with a stacked thickness of ≤20mm. First, pre-freeze at -5°C for 5 hours, and then set the vacuum degree Under the condition of 69-74Pa, control the temperature from -40°C to 45°C for vacuum drying in stages, select the heating rate as 20°C / h, and automatically dry the salvia miltiorrhiza; the specific drying temperature and treatment time for stage-by-stage treatment as follows:

[0060] One stage: -40℃, temperature 3h

[0061] Second stage: -35℃, temperature 2h

[0062] Three stages: -30℃, temperature 3h

[0063] Four stages: -25℃, temperature 3h

[0064] Five stages: -20℃, temperature 2h

[0065] Six sections: -15℃, temperature 3h

[0066] Seven stages: 0℃, temperature 2h

[0067] Eight sections: 5°C, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com