A common anode diode device and its preparation method

A diode and common anode technology, which is applied in the field of common anode diode devices and its preparation, can solve the problems that the diode cathode cannot be directly connected to, poor current carrying capacity, and poor heat dissipation of the product, so as to reduce the number of uses and improve the surge capacity , Improve the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

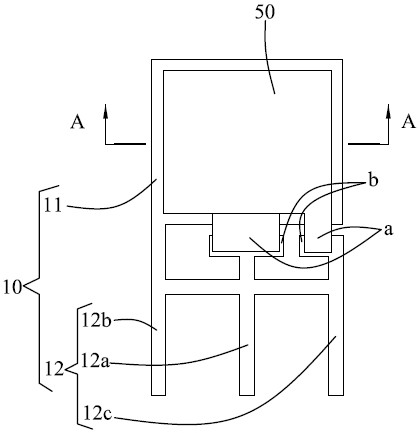

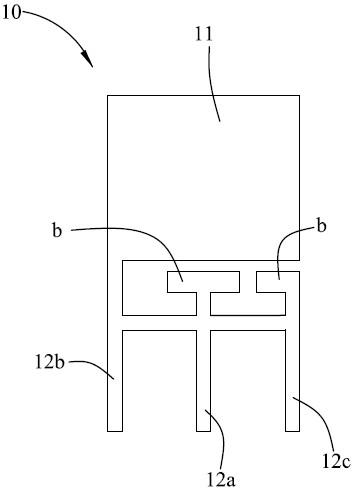

[0051] see Figure 1-Figure 7 , shows the common anode diode device in Embodiment 1 of the present invention, including a conductive support 10, a first diode chip 20, an anode copper sheet 30, a second diode chip 40 and a cathode copper sheet 50, wherein:

[0052] The conductive bracket 10 includes a heat sink 11 and at least two pins 12 arranged on one side of the heat sink 11, and the first diode chip 20 is welded on the heat sink 11 in a way that the cathode faces downward and the anode faces upward, so that The cathode of the first diode chip 20 is fully dissipated by the fins 11 , thereby improving the cooling effect of the cathode of the first diode chip 20 . The anode copper sheet 30 is laminated and welded on the anode of the first diode chip 20, so that the anode of the first diode chip 20 can contact the anode copper sheet 30 in a large area, and the second diode chip 40 faces the cathode The upper anode is stacked and welded on the anode copper sheet 30 so that th...

Embodiment 2

[0059] see Figure 10 , Embodiment 2 of the present invention proposes a method for preparing a common anode diode device, which is used to prepare the common anode diode device in the first embodiment above. The method includes steps S01-step S10, wherein:

[0060] Step S01 , providing a conductive support 10 .

[0061] Wherein, the conductive support 10 is preferably a copper support.

[0062] Step S02 , applying or brushing the first solder paste 1 on the heat sink 11 of the conductive bracket 10 .

[0063] Step S03 , placing the first diode chip 20 with the cathode facing downwards and the anode facing upwards on the first solder paste 1 for soldering.

[0064] Step S04 , applying or brushing the second solder paste 2 on the anode of the first diode chip 20 .

[0065] Step S05 , placing the anode copper sheet 30 on the second solder paste 2 for welding, and welding the anode copper sheet 30 to one pin 12 of the conductive support 10 .

[0066] Step S06 , applying or br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com