Mine paste filling material as well as preparation method and application thereof

A technology for filling materials and mines, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of environmental pollution, non-application, etc., achieve high preparation costs, simple and easy-to-operate preparation methods, and facilitate industrial promotion and use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

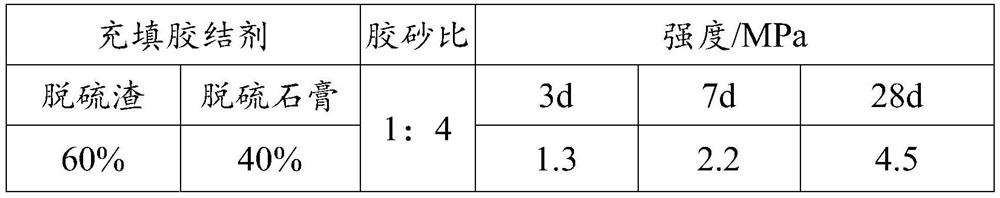

Embodiment 1

[0041] A production method of mine paste filling material, including filling cement as follows: the raw materials used in this embodiment are all solid waste, wherein the percentage content of each raw material is: 60% of pre-desulfurization slag of molten iron, 40% of power plant desulfurization gypsum. The mass of water added in this embodiment is 25% of the mass of all the cemented filling materials, that is, the pre-desulfurized hot metal slag + power plant desulfurized gypsum + ultra-fine tailings on a dry basis, that is, the slurry concentration is 80%. The dosage of water reducer is 0.2% of the dry mass of cemented filling.

[0042] The main chemical components of desulfurization gypsum in power plants are CaO, SO 3 and a small amount of SiO 2 etc., the content of dihydrate gypsum in its phase is 91.6%.

[0043] The main chemical components of KR hot metal pre-desulfurization slag are CaO and SiO 2 , Fe 2 o 3 、Al 2 o 3 And a certain amount of S, of which CaO acco...

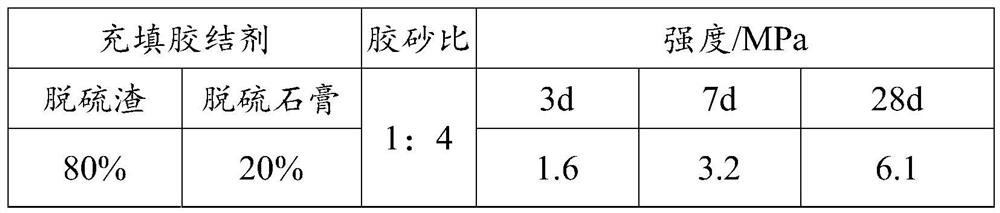

Embodiment 2

[0054] A production method for mine paste filling, including filling cement as follows: the raw materials used in this embodiment are all solid waste, and the percentage content of each raw material is: 80% of pre-desulfurization slag of molten iron, 20% of power plant desulfurization gypsum. The mass of water added in this embodiment is 25% of the mass of all the cemented filling materials, that is, the pre-desulfurized hot metal slag + power plant desulfurized gypsum + ultra-fine tailings on a dry basis, that is, the slurry concentration is 80%. The dosage of water reducer is 0.3% of the dry mass of cemented filling.

[0055] The main chemical components of desulfurization gypsum in power plants are CaO, SO 3 and a small amount of SiO 2 etc., the content of dihydrate gypsum in its phase is 91.6%.

[0056] The main chemical components of KR hot metal pre-desulfurization slag are CaO and SiO 2 , Fe 2 o 3 、Al 2 o 3 And a certain amount of S, of which CaO accounts for 74....

Embodiment 3

[0067] A production method of mine paste filling material, including filling cement as follows: the raw materials used in this embodiment are all solid waste, and the percentage content of each raw material is: 50% of molten iron pre-desulfurization slag, and 50% of power plant desulfurization gypsum. The mass of water added in this embodiment is 25% of the mass of all the cemented filling materials, that is, the pre-desulfurized hot metal slag + power plant desulfurized gypsum + ultra-fine tailings on a dry basis, that is, the slurry concentration is 80%. The dosage of water reducer is 0.2% of the dry mass of cemented filling.

[0068] The main chemical components of desulfurization gypsum in power plants are CaO, SO 3 and a small amount of SiO 2 etc., the content of dihydrate gypsum in its phase is 91.6%.

[0069] The main chemical components of KR hot metal pre-desulfurization slag are CaO and SiO 2 , Fe 2 o 3 、Al 2 o 3 And a certain amount of S, of which CaO account...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com