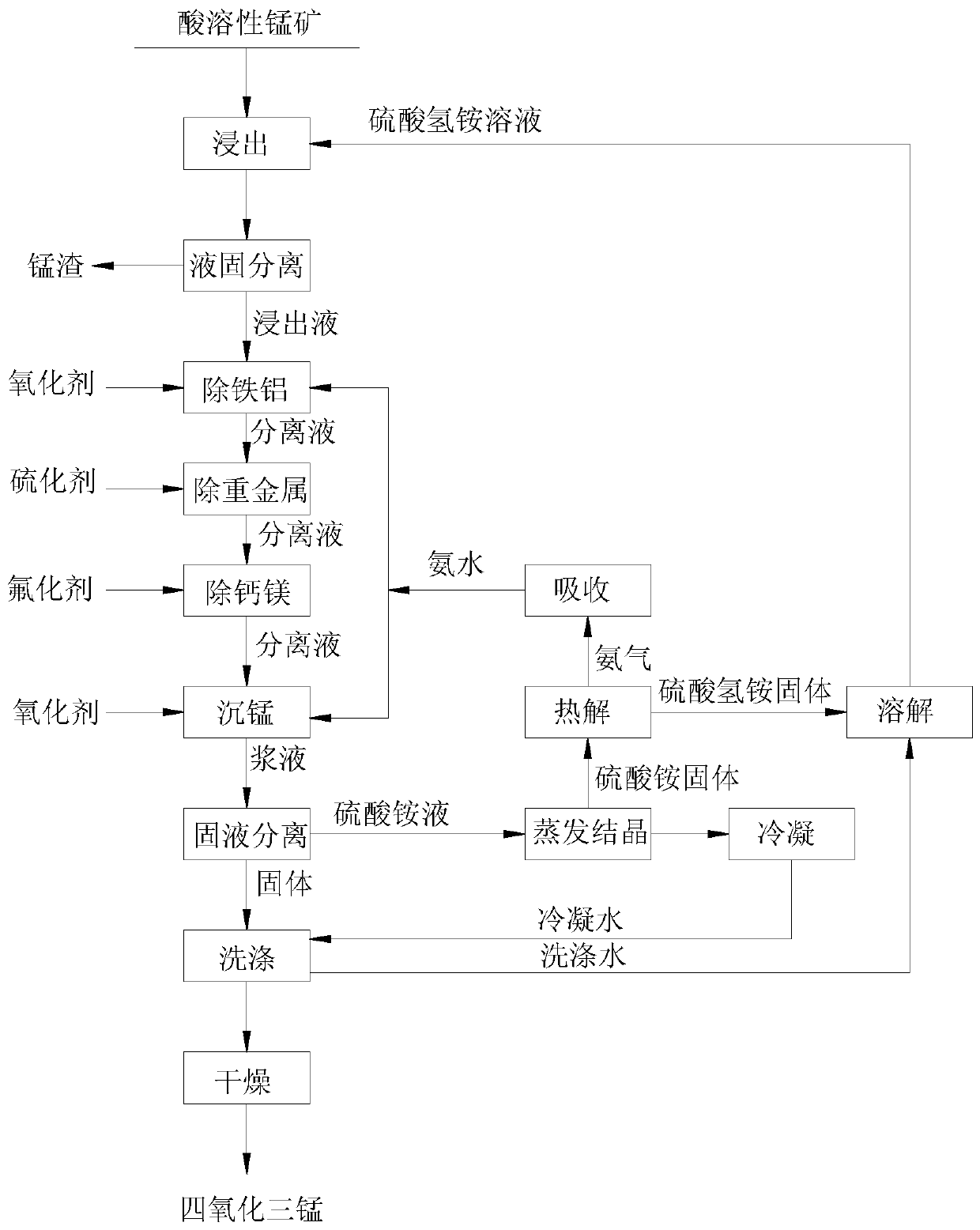

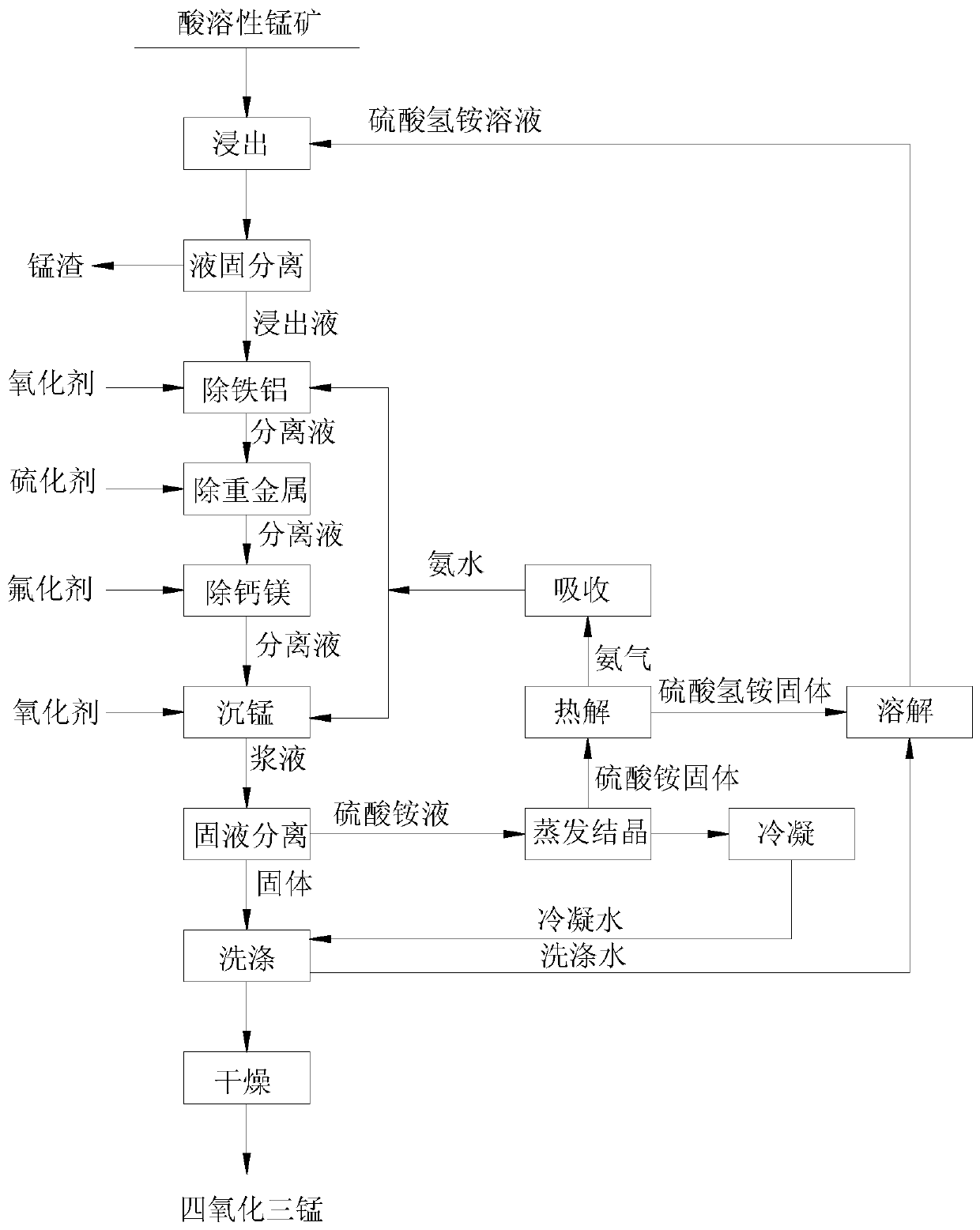

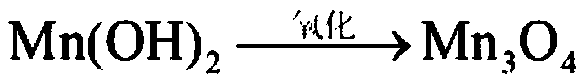

Method for preparing trimanganese tetraoxide by using acid-soluble manganese ore based on sulfur and ammonia cycle

A manganese tetroxide, acid-soluble technology, applied in manganese oxide/manganese hydroxide and other directions, can solve the problems of heavy metal pollution of soil, lower price of ammonium sulfate, low utilization value, etc., to reduce the energy consumption of pyrolysis and comprehensive utilization. High rate and the effect of reducing purchases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Utilize manganese carbonate ore to prepare manganese tetroxide, and the specific process steps are as follows:

[0032] (1) leaching: utilize ammonium hydrogen sulfate solution as leaching agent to mix slurry with manganese carbonate ore, the mol ratio of manganese in ammonium hydrogen sulfate and manganese carbonate ore is 3:1, so that the manganese of manganese ore is converted into soluble manganese sulfate, and the obtained slurry is carried out Press filtration to obtain waste residue and a separation liquid containing manganese sulfate;

[0033] (2) Purification and impurity removal: air is introduced into the separation liquid obtained in step (1), so that Fe in the leaching liquid is 2+ oxidized to Fe 3+ , and adding ammonia water to adjust the pH to 5.5 to convert it into Fe(OH) 3 precipitation, while the Al in the leaching solution 3+ Converted to Al(OH) 3 Precipitation, solid-liquid separation to obtain Fe(OH) 3 , Al(OH) 3 Precipitation and separation l...

Embodiment 2

[0043] The manganese oxide ore after the reduction of pyrolusite is used to prepare manganese tetroxide, and the operation steps are as follows:

[0044] (1) Leaching: using ammonium hydrogen sulfate solution as a leaching agent to mix with the original manganese oxide ore, the molar ratio of ammonium hydrogen sulfate and manganese in the manganese ore is 2.5:1, so that the manganese in the manganese ore is converted into soluble manganese sulfate, and the The obtained slurry is centrifuged to obtain a waste residue and a separation liquid containing manganese sulfate.

[0045] (2) purifying and removing impurities: adding hydrogen peroxide to the separation liquid obtained in step (1) to make Fe in the leaching solution 2+ oxidized to Fe 3+ , and adding ammonia water to adjust the pH to 6.0 to convert it into Fe(OH) 3 precipitation, while the Al in the leaching solution 3+ Converted to Al(OH) 3 Precipitation, solid-liquid separation to obtain Fe(OH) 3 , Al(OH) 3 Precipi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com