A method of directly sintering fly ash to prepare glass-ceramics

A technology of glass-ceramic and fly ash, which is applied in glass forming, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of low utilization rate of fly ash, low utilization rate of waste residue, high energy consumption in production, and achieve good performance. , the effect of low energy consumption and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

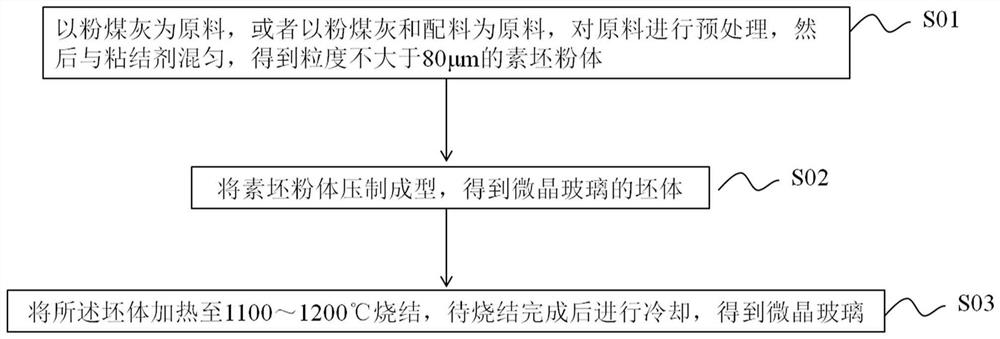

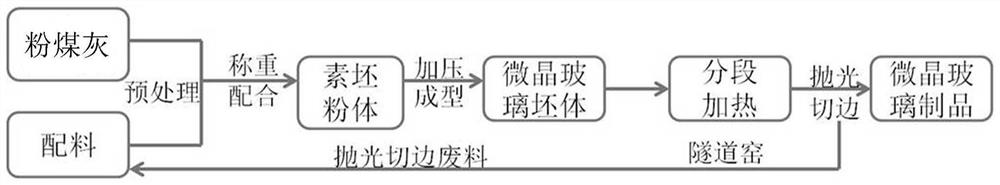

Method used

Image

Examples

example 1

[0081] The specific preparation method is as follows:

[0082] 1) Take high-calcium fly ash from a certain place in Xinjiang as the whole raw material without adding auxiliary materials. After drying at 105°C for 2 hours, carry out ball mill classification, take fly ash powder with a particle size of 48 μm and add 5% fly ash mass percentage The vinyl alcohol is uniformly mixed to obtain a glass-ceramic green body powder.

[0083] 2) The green body powder is flatly spread in the forming abrasive tool, and the glass-ceramic green body is obtained after holding the pressure at 20 MPa for 30 seconds with a green body forming press.

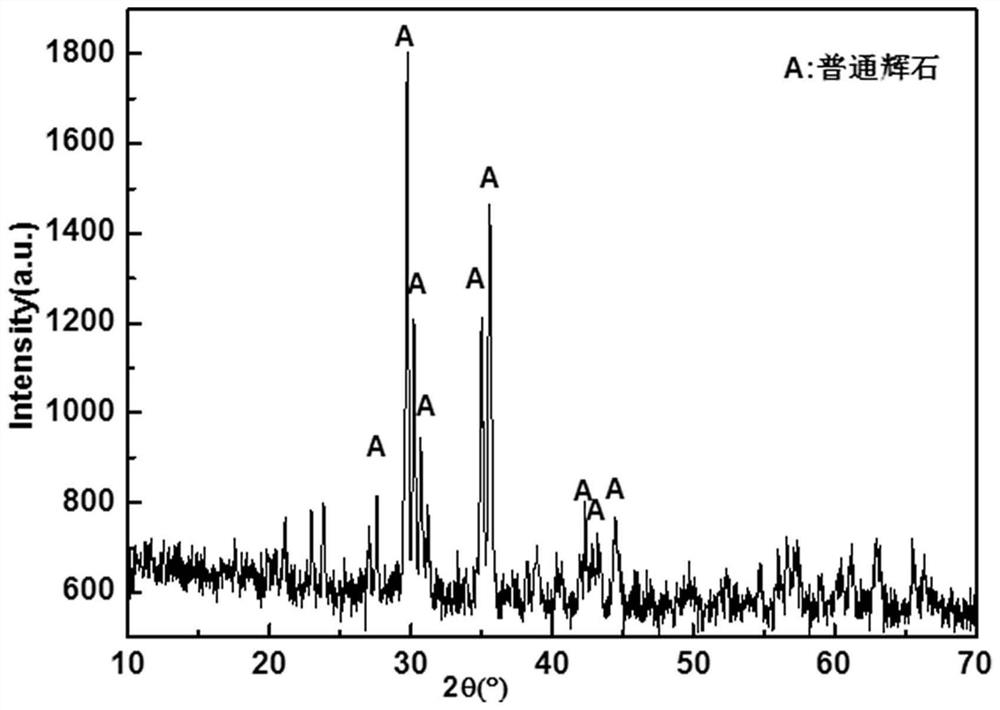

[0084] 3) Put the glass-ceramic body into the tunnel kiln and raise the temperature directly from room temperature to 950°C at a heating rate of 10°C / min and keep it warm for 30 minutes, then raise the temperature to 1180°C at a heating rate of 5°C / min and keep it warm for 60 minutes. After the furnace cools down, the samples are taken out, polished ...

example 2

[0087] The specific preparation method is as follows:

[0088] 1) Take the fly ash in Example 1 as the main raw material, choose waste glass and perlite as the ingredients, dry the fly ash and the ingredients at 105°C for 2 hours, crush and classify by ball milling, and separate the components according to mass percentage 90% of fly ash, 5% of waste glass, and 5% of perlite are weighed and mixed, and the powder with a particle size of 37 μm is added to 5% by mass of glycerin and mixed evenly to obtain a glass-ceramic green body powder;

[0089] 2) The green body powder is flatly spread in the forming abrasive tool, and the green body forming press is used to hold the pressure at 30 MPa for 30 seconds to obtain the glass-ceramic green body.

[0090] 3) Put the glass-ceramic body into the tunnel kiln and raise the temperature directly from room temperature to 1160°C for 60 minutes at a rate of 10°C / min. After cooling down with the furnace, take out the sample, polish it, and trim ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com