A method of directly sintering asbestos tailings to prepare functional glass-ceramics

A technology of asbestos tailings and glass-ceramics, which is applied in glass forming, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of long process flow, cumbersome process, and high energy consumption in production, and achieve simple process flow and facilitate industrial promotion , the effect of high added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

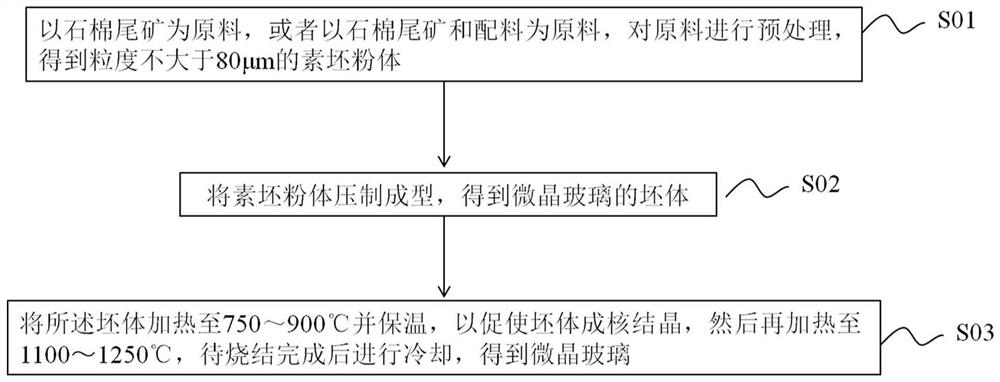

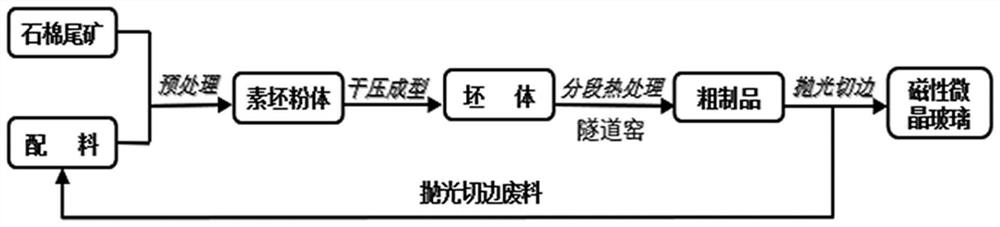

Method used

Image

Examples

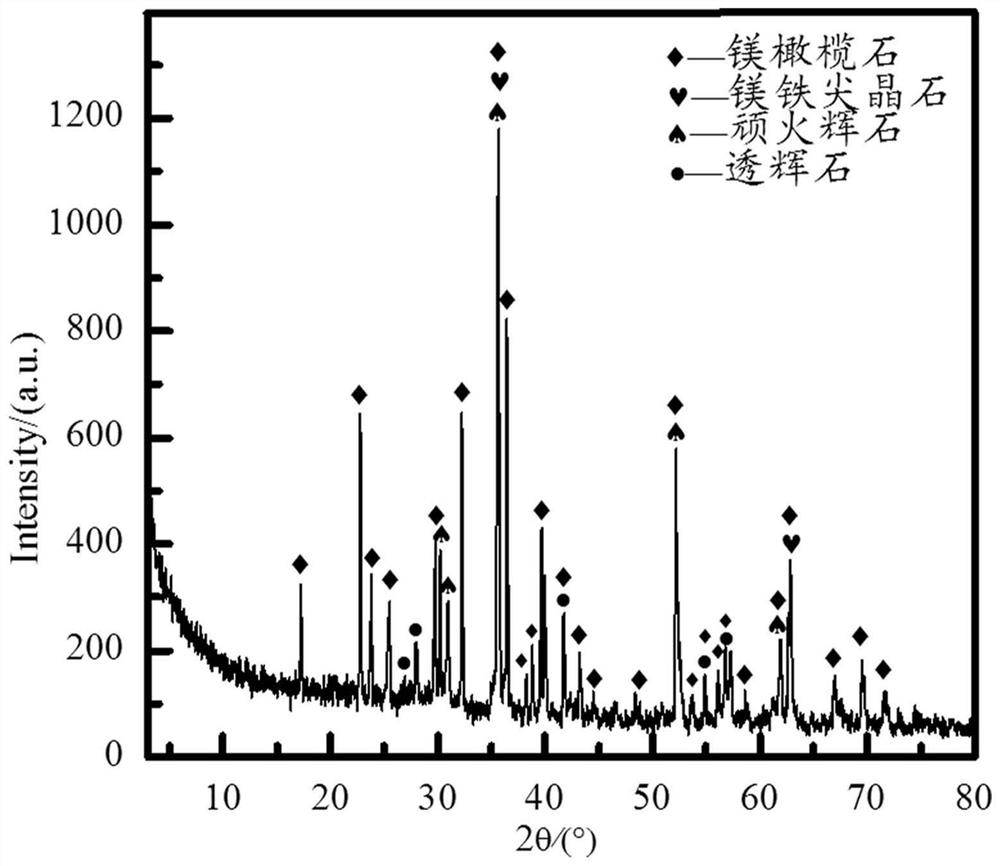

example 1

[0108] 1) After the asbestos tailings and ingredients are pretreated, weigh and mix them uniformly to obtain a glass-ceramic green body powder. Asbestos tailings chemical composition in weight percent: MgO 40%, SiO 2 35%, Fe 2 o 3 10%, CaO 6%, Al 2 o 3 1%, Cr 2 o 3 0.5%, NiO 0.3%, K 2 O 0.2%, MnO 0.1%, BaO 0.05%, Co 3 o 4 0.03%, loss on ignition 6.82%; auxiliary materials: waste glass, feldspar (that is, potassium feldspar or albite), accounting for 5% and 3% of the mass fraction of asbestos tailings respectively; pretreatment: asbestos tailings at 700 ° C After pre-roasting for 1 hour and dehydration, it is uniformly mixed with auxiliary materials and ball-milled to 50um to obtain a green body powder.

[0109] 2) Spread the glass-ceramic green body powder obtained in step 1) flatly on a forming abrasive tool, and dry-press molding with a green body forming press to obtain a glass-ceramic green body. Among them, the pressure of dry pressing is 30MPa, and the hol...

example 2

[0113] 1) After pretreatment of asbestos tailings and ingredients, weigh and mix uniformly to obtain glass-ceramic green body powder; wherein, the chemical composition of asbestos tailings is in weight percentage: MgO 38%, SiO 2 35%, Fe 2 o 3 8%, CaO 15%, Al 2 o 3 1%, Cr 2 o 3 0.5%, NiO 0.3%, K 2 O 0.2%, MnO 0.1%, BaO 0.05%, Co 3 o 4 0.02%, loss on ignition 1.83%; auxiliary materials: caustic soda, potassium feldspar, accounting for 5% and 3% of the mass fraction of asbestos tailings respectively. Pretreatment: The asbestos tailings are pre-roasted at 750°C for 1 hour, dehydrated, mixed evenly with auxiliary materials and ball-milled to 50um to obtain a green body powder.

[0114] 2) Spread the glass-ceramic green body powder obtained in step 1) flatly on a forming abrasive tool, and dry-press molding with a green body forming press to obtain a glass-ceramic green body. Among them, the pressure of dry pressing is 50MPa, and the holding time is 60s.

[0115] 3) P...

example 3

[0118] 1) After the asbestos tailings and ingredients are pretreated, weigh and mix them uniformly to obtain a glass-ceramic green body powder. Asbestos tailings chemical composition in weight percent: MgO 40%, SiO 2 38%, Fe 2 o 3 8%, CaO 6%, Al 2 o 3 1%, Cr 2 o 3 0.5%, NiO0.3%, K 2 O 0.2%, MnO 0.1%, BaO 0.05%, Co 3 o 4 0.03%, loss on ignition 5.82%; auxiliary materials: caustic soda, potassium feldspar, accounting for 5% and 3% of asbestos tailings mass fraction respectively; pretreatment: asbestos tailings are pre-roasted at 750°C for 1 hour and dehydrated, then uniformly mixed with auxiliary materials and ball milled to 50um to get bisque powder.

[0119] 2) Spread the glass-ceramic green body powder obtained in step 1) flatly on a forming abrasive tool, and dry-press molding with a green body forming press to obtain a glass-ceramic green body. The pressure of dry pressing is 80MPa, and the holding time is 60s.

[0120] 3) Place the glass-ceramic blank obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com