Energy-saving and anti-blocking coal gas washing method

A gas washing and anti-blocking technology, which is applied in the field of coal chemical industry, can solve problems such as inability to protect the descending pipe, clogging of the coal gas outgoing pipeline due to ash accumulation, burning through the descending pipe, etc., so as to reduce processing power consumption and equipment maintenance costs, and avoid burning Wear accidents, the effect of lowering the surface temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

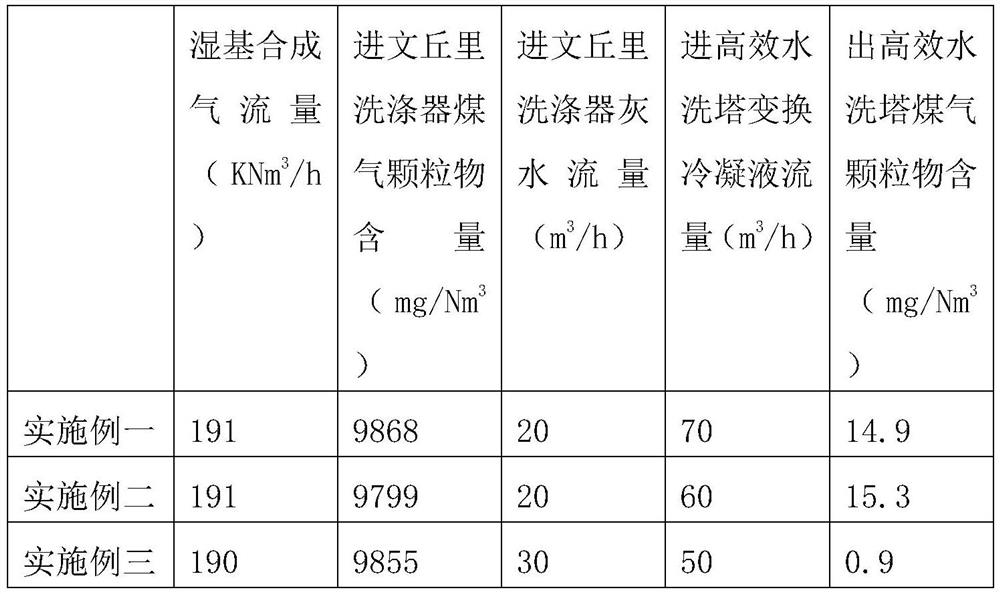

Examples

Embodiment

[0030] 1. Equipment

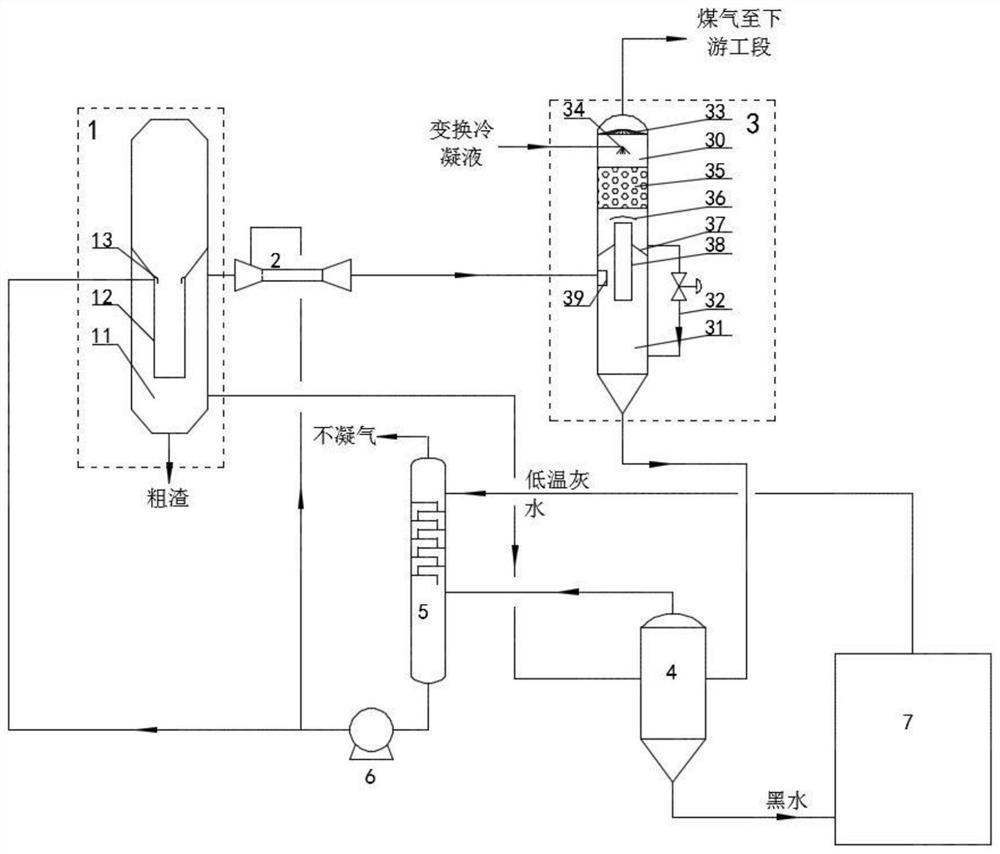

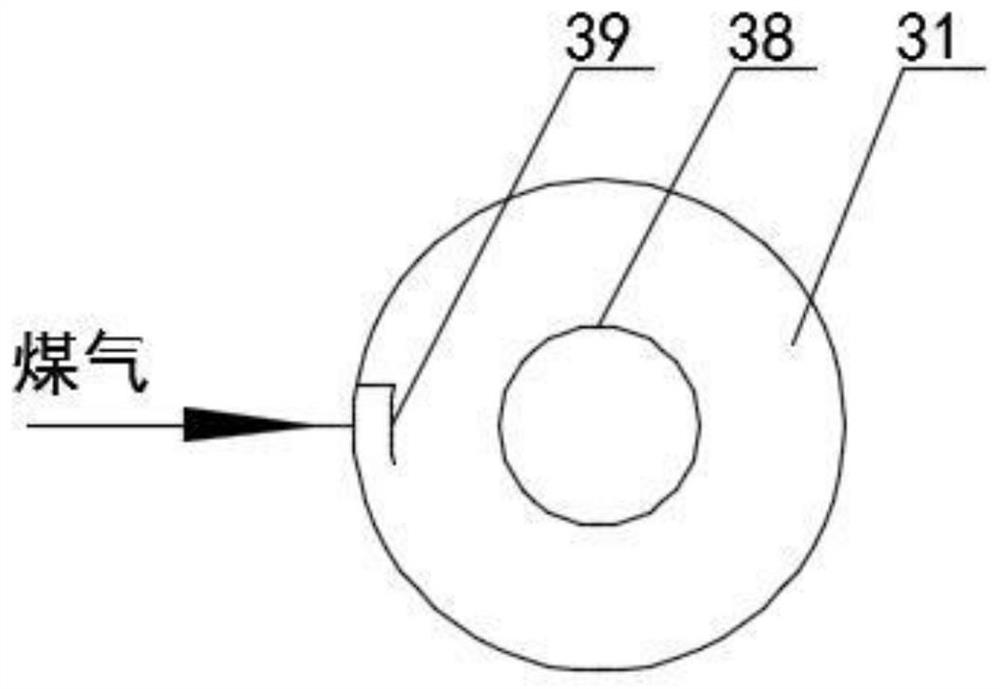

[0031] as attached figure 1 As shown, the energy-saving and anti-blocking gas scrubbing system is mainly composed of a gasifier 1, a Venturi scrubber 2, a high-efficiency water scrubber 3, a high-pressure flash tank 4, a flash steam scrubber 5, and a high-pressure gray water pump 6.

[0032] The gas outlet pipe of the quenching chamber of the gasifier 1 is connected to the air inlet of the Venturi scrubber 2, and the length of the pipe is not longer than 5 meters to avoid dust accumulation in the pipe in front of the Venturi scrubber 2. The venturi scrubber 2 gas outlet pipe is connected to the high-efficiency water scrubber 3 gas inlet. The black water outlet pipeline at the lower end of the high-efficiency water washing tower 3 is connected to the high-pressure flash tank 4 . The black water outlet at the lower end of the high-pressure flash tank 4 is connected to the black water treatment unit 7, and the flash steam outlet pipe at the top of the flas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com