Online detection method for granulation effect of cylinder mixer

A cylinder mixing and detection method technology, which is applied in the testing of machines/structural components, measuring devices, particle size analysis, etc., can solve the problem that the granulation effect of the mixer cannot be measured and described, local loose materials or large sticky materials appear, difficult Precise process control and other issues to achieve the effect of improving visual analysis difficulties, improving accuracy and reliability, and fast and rapid analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] The online detection method of the present embodiment comprises:

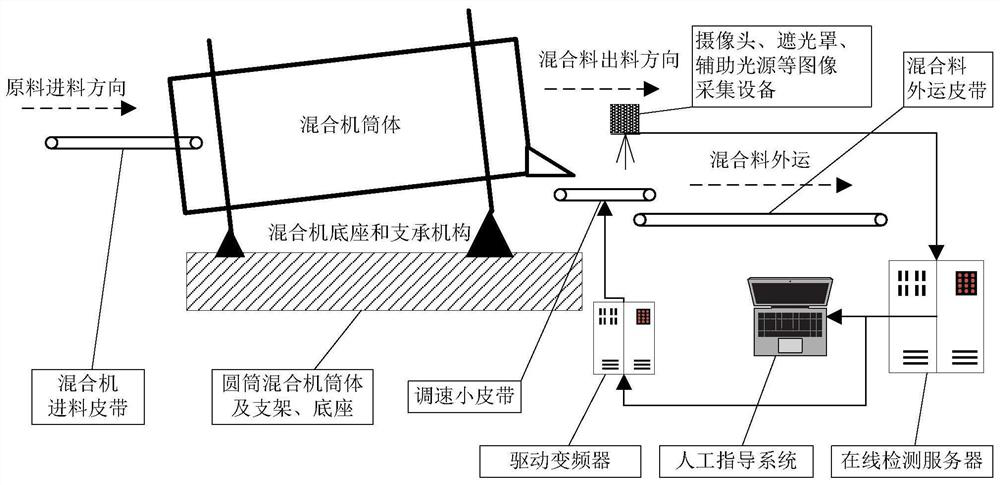

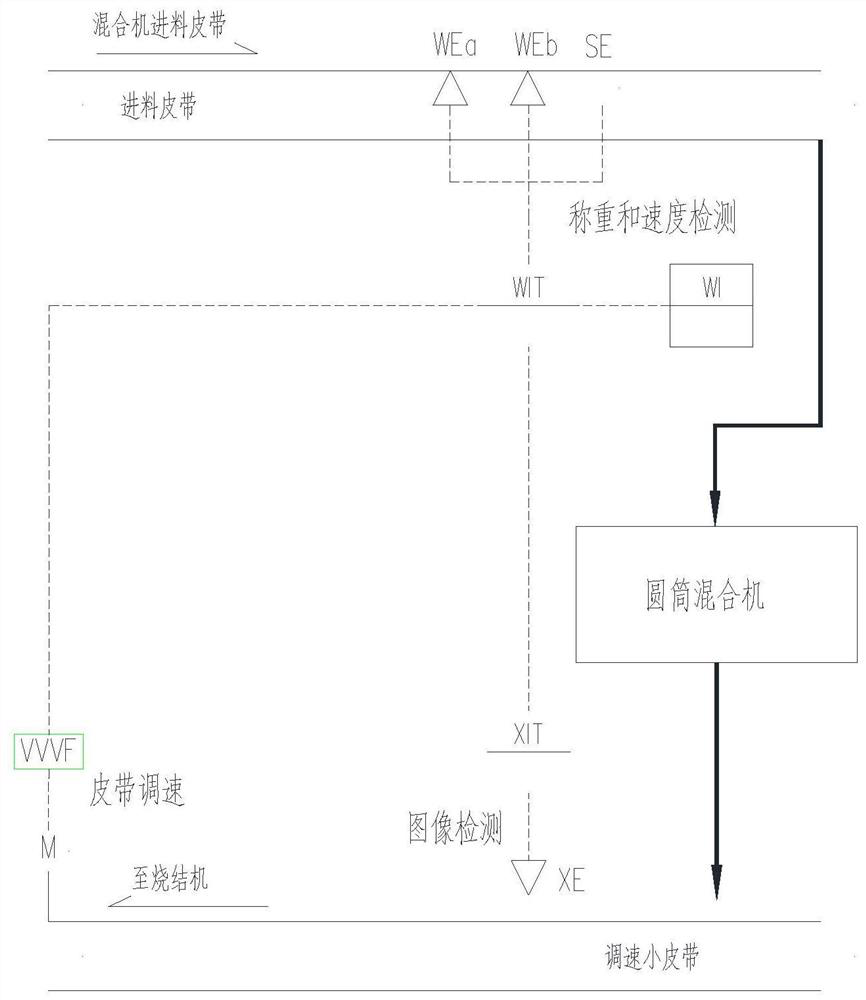

[0060] The first step: the sintering raw material is transported to the entrance of the mixer through the feeding belt, and a weighing detection device and a speed detection device are installed at the feeding belt, and the feeding speed of the sintering raw material is obtained through weighing and belt speed measurement. The sintered raw materials are stirred and mixed in a cylinder mixer to form a granular mixture.

[0061] Step 2: The mixed material at the outlet of the cylinder mixer falls onto the belt conveyor at the outlet, and the belt conveyor at the outlet changes the running speed through the frequency converter to adjust the thickness of the material layer.

[0062] Step 3: According to the collection cycle, the camera collects the material surface image of the belt conveyor at the discharge outlet at a fixed point and time, and uploads it to the online detection server.

[0063] Step 4: Th...

Embodiment 2

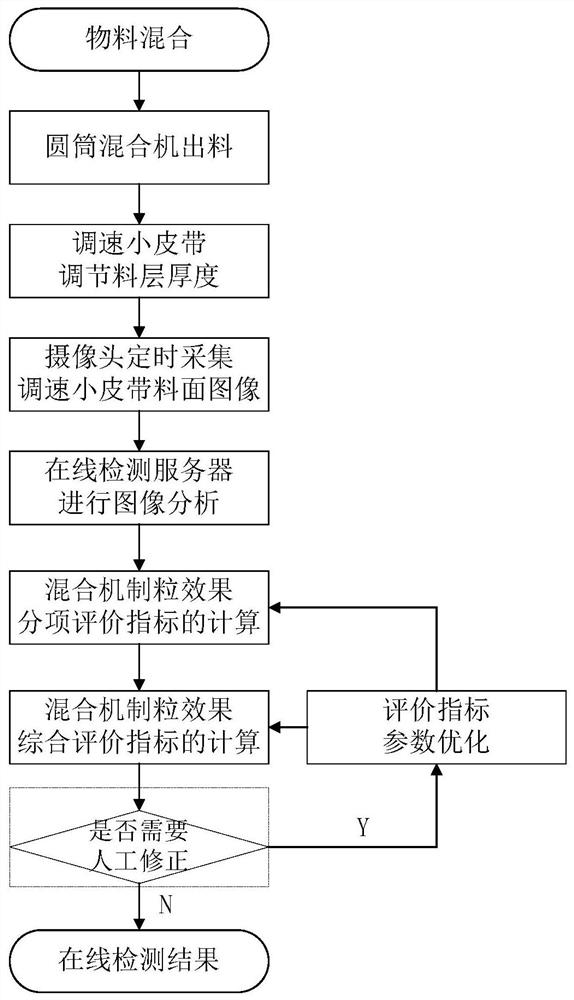

[0099] The online detection method of this embodiment sees image 3 :

[0100] The first step: the sintering raw material is transported to the entrance of the mixer through the feeding belt, and a weighing detection device and a speed detection device are installed at the feeding belt, and the feeding speed of the sintering raw material is obtained through weighing and belt speed measurement. The sintered raw materials are stirred and mixed in a cylinder mixer to form a granular mixture.

[0101] Step 2: The mixed material at the outlet of the cylinder mixer falls onto the belt conveyor at the outlet, and the belt conveyor at the outlet changes the running speed through the frequency converter to adjust the thickness of the material layer.

[0102] Step 3: According to the collection cycle, the camera collects the material surface image of the belt conveyor at the discharge outlet at a fixed point and time, and uploads it to the online detection server.

[0103] Step 4: The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com