Automatic cigar tobacco air-curing room

A technology of cigar tobacco leaf and drying room, which is applied in the fields of tobacco, tobacco preparation, application, etc. It can solve the problems of low automation level, unstable quality of drying, and large labor input, so as to reduce labor input, shorten drying time, The effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

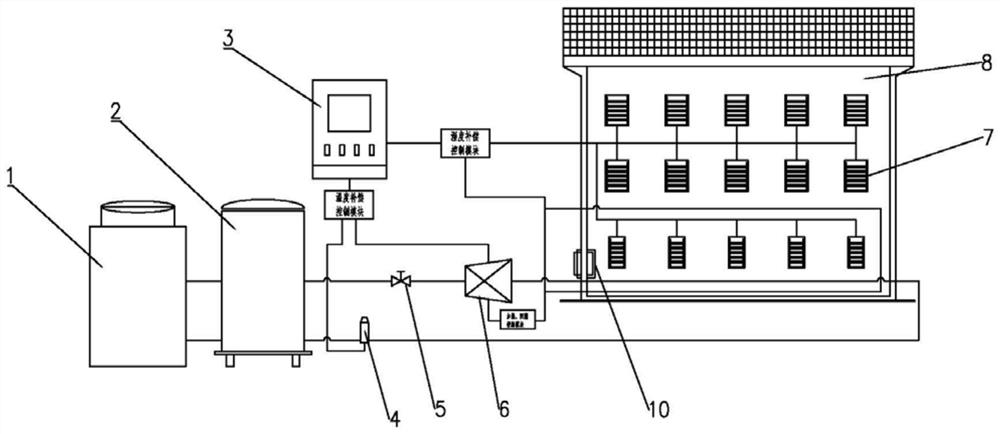

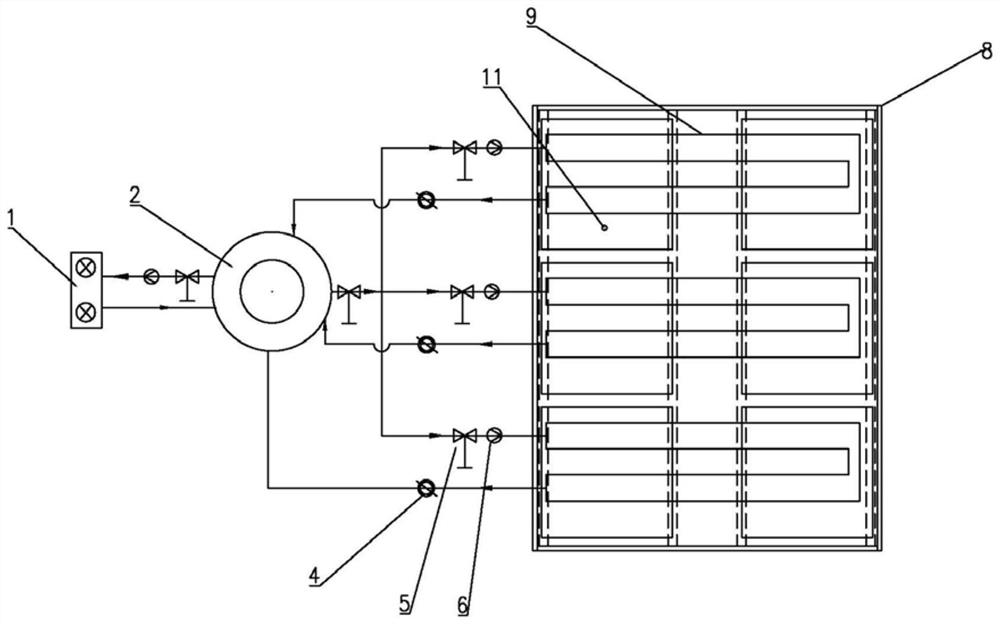

[0024] as attached figure 1 , 2 As shown, the present invention includes a temperature compensation control module, a humidity compensation control module and a humidification resurgence module, wherein the temperature compensation control module consists of an air source heat pump 1, a thermal insulation water tank 2, a valve 5, a water pump 6, a throttle valve 4, and an automatic dehumidification damper 7, the circulation pipe network 9 and the intelligent controller 3 together form a temperature compensation control module; the humidity compensation control module consists of an insulated water tank 2, a valve 5, a water pump 6, a throttle valve 4, an automatic dehumidification damper 7 and an intelligent controller 3 Humidity compensation control module; the humidification and moisture recovery module is connected with the circulation pipe network through the humidification and moisture recovery device, and under the control of the intelligent controller 3, it can humidify...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com