Pretreatment device for food additives

A pretreatment device and food additive technology, applied in grain processing, transportation and packaging, chemical/physical processes, etc., can solve problems such as inconvenient maintenance or cleaning, single function, poor crushing or mixing effect, etc., to achieve easy disassembly and maintenance , long service life, small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

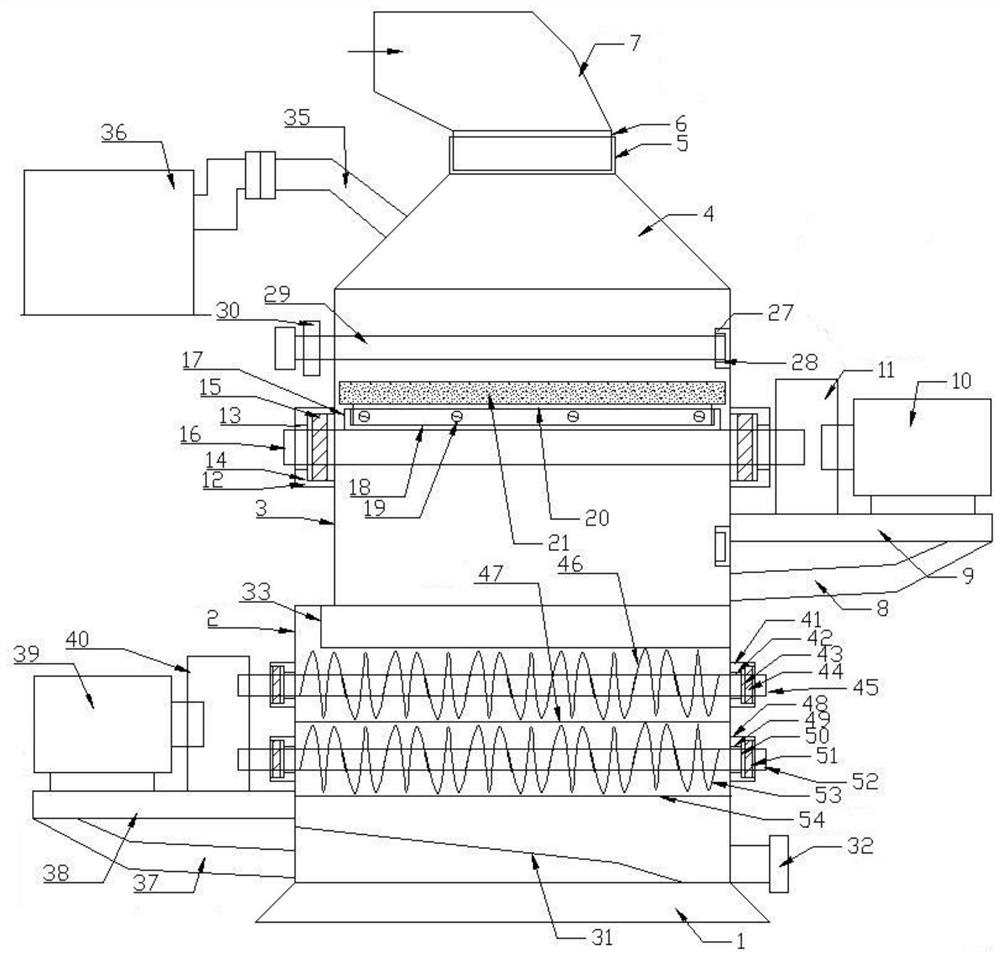

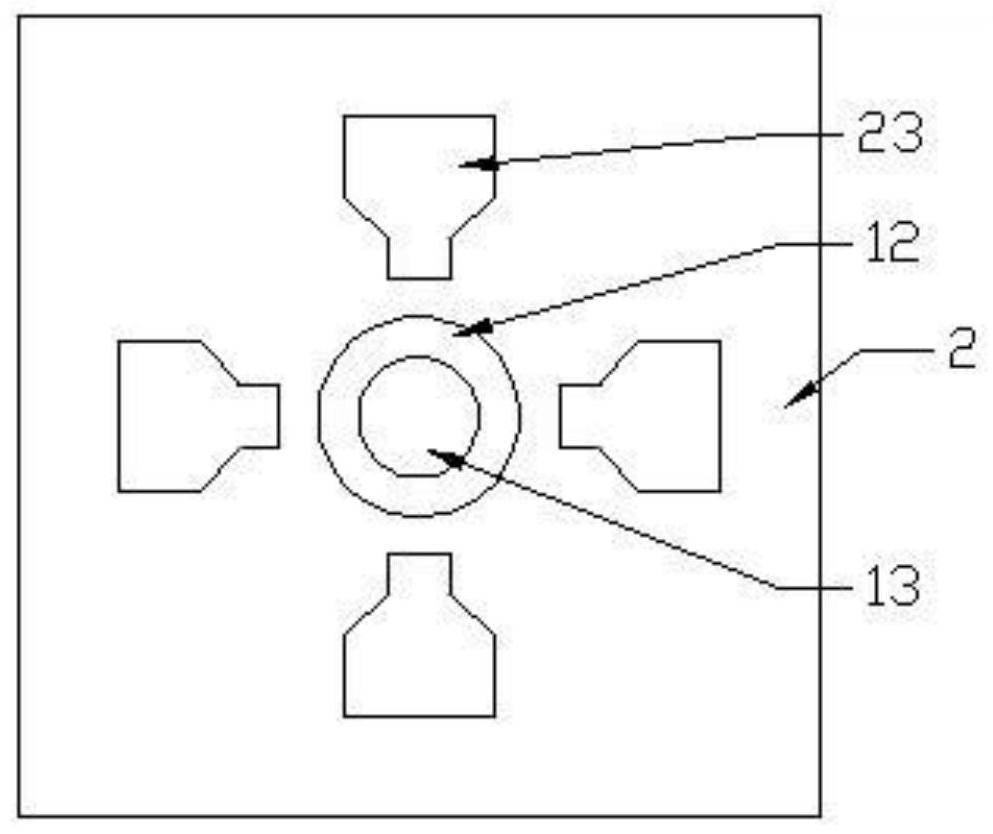

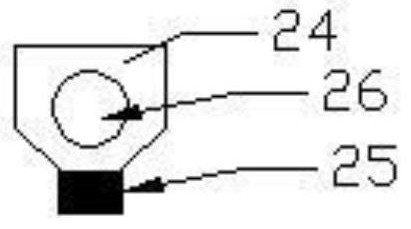

[0027] Such as Figure 1 to Figure 10The shown pretreatment device for food additives consists of a vertical box assembly and a detachable crushing assembly used in conjunction with the vertical box assembly; the vertical box assembly includes a base 1, and The first hollow box body 2 that is arranged on the base 1, and the second hollow box body 3 that is arranged on the first hollow box body 2, and the hollow sealing cover 4 that is arranged on the second hollow box body 3, and is arranged on The feed port 7 on the hollow sealing cover 4, the slope-shaped collecting plate 31 arranged on the surface of the base 1 and located in the first hollow box 2, and the vacuum discharge provided on the bottom side of the first hollow box 2 Conduit 32: The detachable crushing assembly includes a first inclined support plate 8 arranged on the outer wall of one side of the second hollow box 3, and is arranged on the outer wall of one side of the second hollow box 3 and is connected with th...

Embodiment 2

[0032] On the basis of Embodiment 1, the pretreatment device applied to food additives also includes a second inclined support plate 37 arranged on the outer wall of one side of the first hollow box 2, and a second inclined support plate 37 arranged on the first hollow box 2- The second fixed plate 38 connected to the side outer wall and the second inclined support plate 37, and the second drive motor 39 and the second gear box 40 that are arranged on the second fixed plate 38 and used in conjunction with each other, and are symmetrically arranged on the first A group of second bearing fixing blocks 41 on the outer walls of the both sides of the hollow box body 2, and the second rotating shaft through hole 42 and the second bearing installation groove 43 that are respectively arranged in the second bearing fixing block 41, and are respectively arranged on the second bearing fixing block 41. The second bearing 44 in the bearing installation groove 43, and the second rotating sha...

Embodiment 3

[0039] On the basis of Embodiment 1 or Embodiment 2 and Embodiment 1 and Embodiment 2, the pretreatment device applied to food additives also includes an air guide tube 35 arranged on the outer wall of the hollow sealing cover 4, and the air guide tube 35 The connected cold source liquid nitrogen machine 36, the above-mentioned structural design can realize the crushing or mixing operation of special additives in a low temperature environment, improve the application range of the overall structure, and solve the problems existing in existing equipment products.

[0040] Embodiment 1 or Embodiment 2 or Embodiment 3 of the present invention, the described pretreatment device that is applied to food additives also includes the strip-shaped collecting plate 33 that is arranged in the upper part of the first hollow box 2, and is respectively arranged in The strip-shaped material guide channel 34 in the strip-shaped material collecting plate 33 realizes the fast material guiding oper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com