Process for preparing metal-based ceramic composite material through secondary pressure application

A ceramic composite material and metal-based technology, which is applied in the technical field of preparing metal-based ceramic composite materials by secondary pressure, can solve the problem of low infiltration rate, achieve the effects of improving quality, convenient operation, and avoiding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

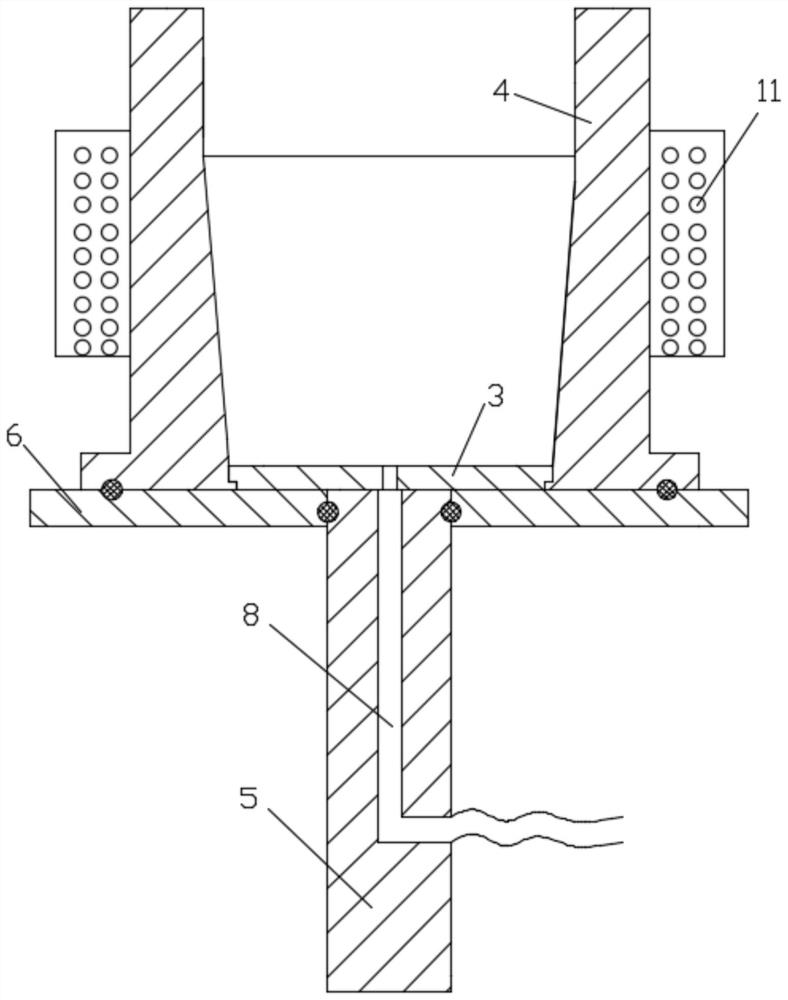

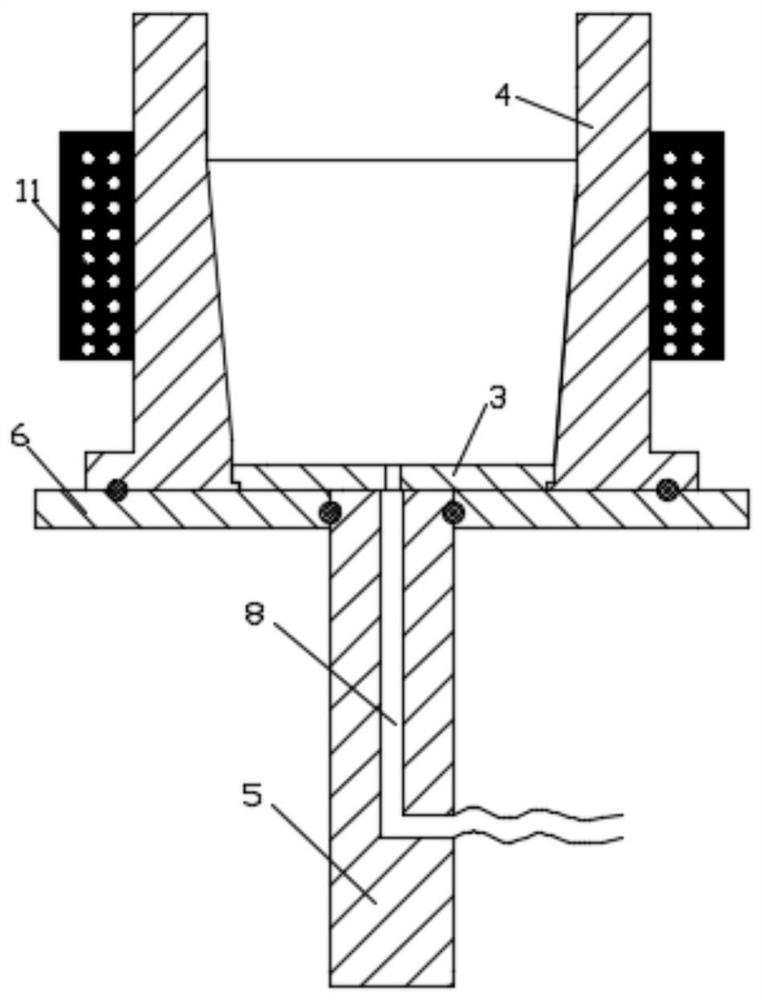

[0091] The present invention needs to use manufacturing tool in manufacturing process, and its specific structure is as follows:

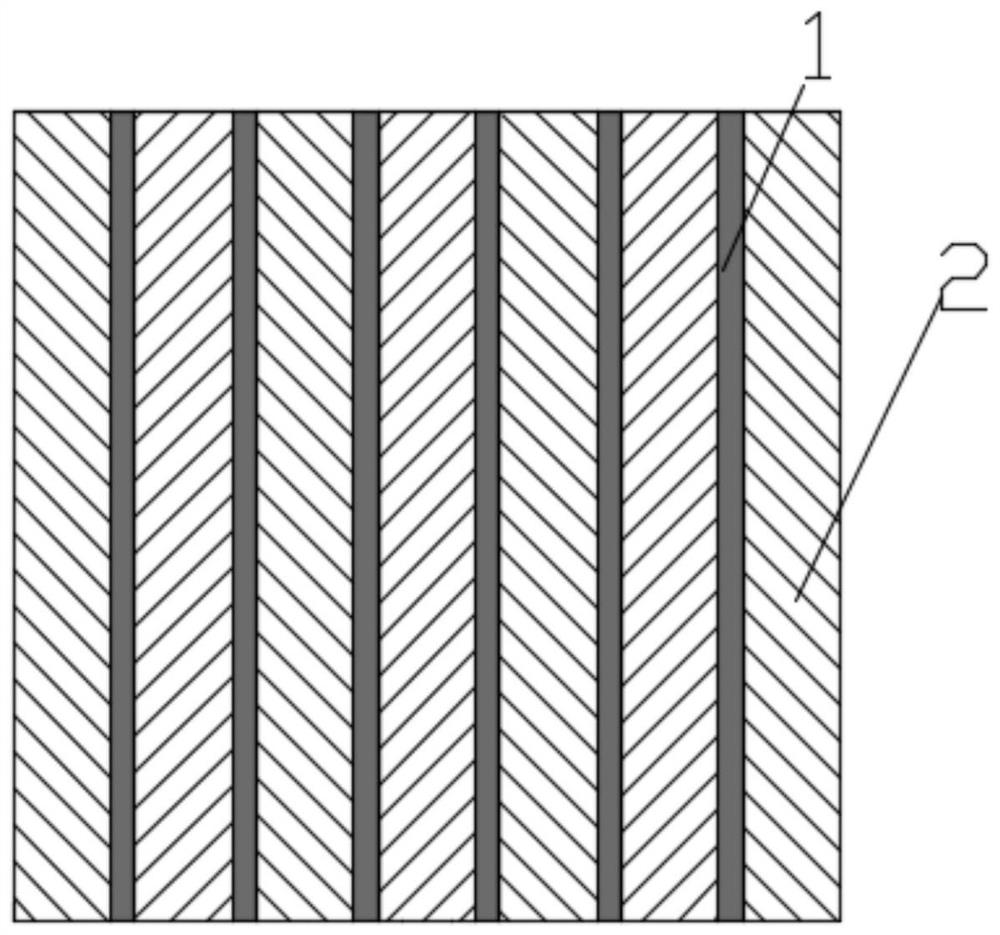

[0092] It mainly includes product forming mold assembly 2, sleeve mold 4, bottom plate 3, pressure head 9, secondary pressure plate 10 and so on.

[0093] The preheated product forming mold assembly 2 is placed on the bottom plate 3 in the cavity of the cover mold 4, and the base plate 3 with the product forming mold assembly 2 is placed on the workbench 6 in the cavity of the cover mold 4. The cover mold 4 and the working There is a sealing groove between the tables 6, between the press mandrel 5 and the workbench 6, and a sealing ring is placed for sealing. There is an air extraction channel 8 in the press mandrel 5, and a valve communicating with the air extraction channel 8 is provided in the middle of the bottom plate 3. The center hole 301, the press ejector rod 5 can drive the product forming mold assembly 2 to lift up and down in the cavity...

specific Embodiment approach 2

[0117] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the ceramic reinforcement powder in the second step is diamond powder, the preheating temperature in the sixth step is 500-600°C, and the holding time is 3 hours. The specific embodiment one is the same.

specific Embodiment approach 3

[0118] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the ceramic reinforcement powder in the second step is silicon carbide powder, the preheating temperature in the sixth step is 600-700°C, and the holding time is 4h. It is the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com