System for inspecting and collecting chemical fiber silk spindles and method for inspecting and collecting chemical fiber silk spindles

A technology of chemical fiber silk and silk ingots, which is applied in the field of inspection and collection of chemical fiber silk ingots. It can solve the problems of affecting the operation of the assembly line, prone to missed inspections, and heavy labor workload of workers, so as to improve inspection efficiency, production efficiency, and labor efficiency. The effect of intensity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

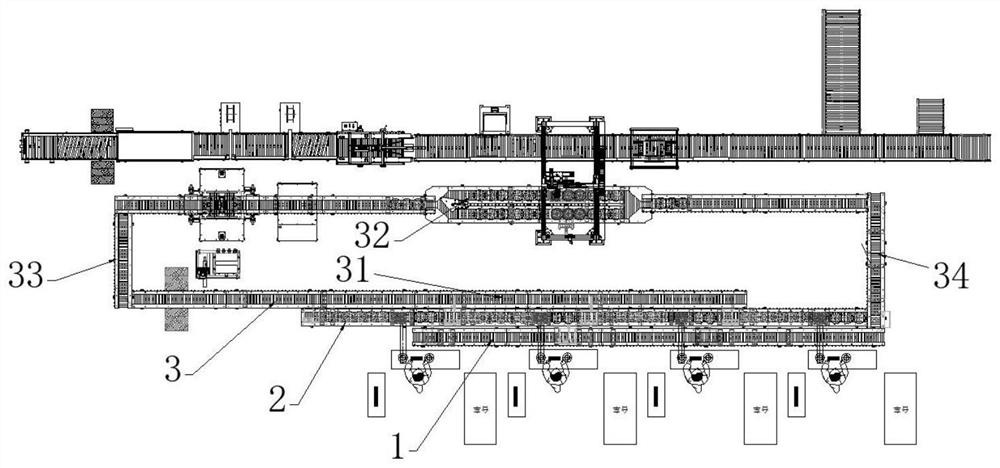

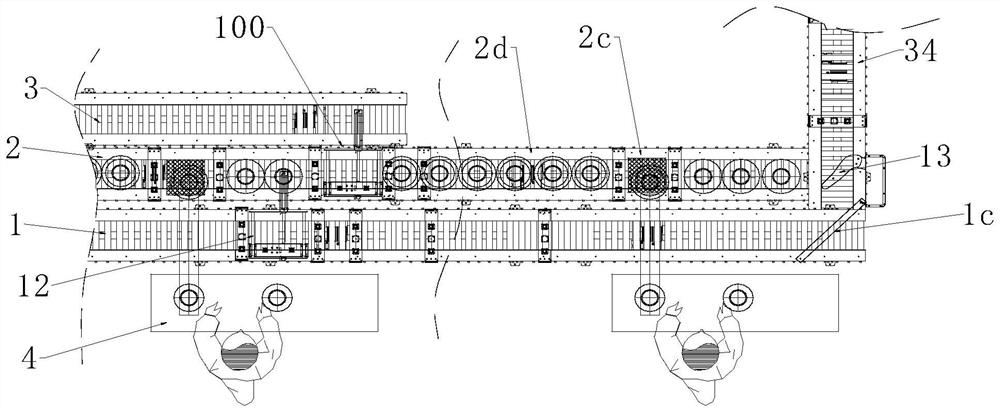

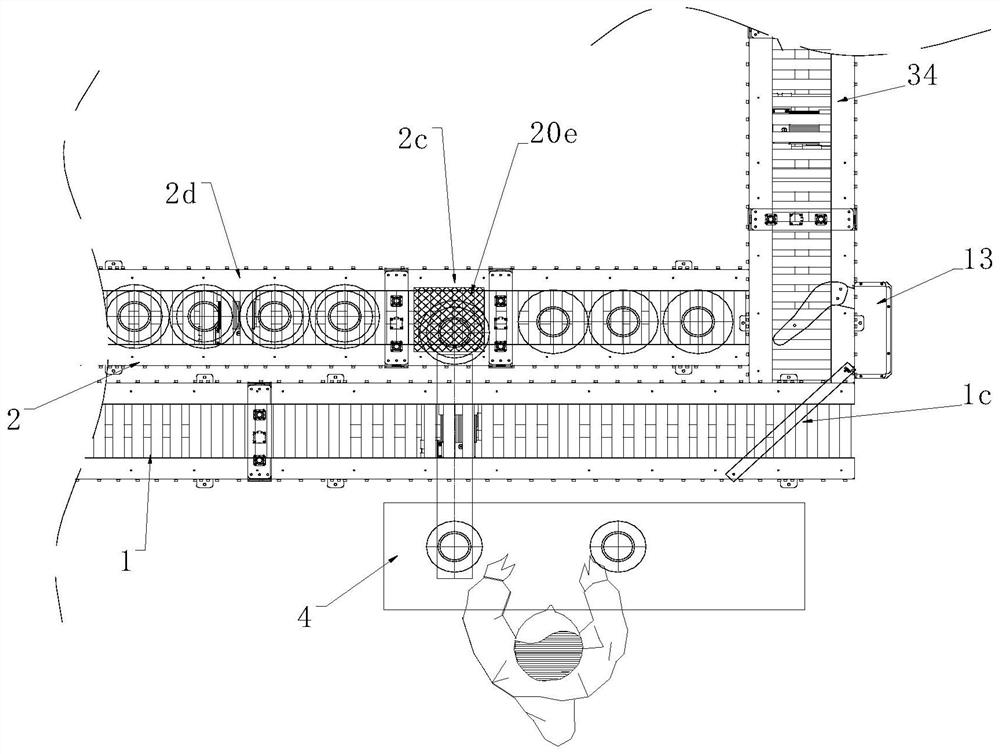

[0060] refer to Figure 1~5 , a system for inspecting and collecting chemical fiber ingots, wherein the system includes tooling 3a, a first conveyor belt 1, a second conveyor belt 2, and a third conveyor belt 3, and the first, second, and third conveyor belts are arranged in parallel , and the second conveyor belt 2 is located between the first conveyor belt 1 and the third conveyor belt 3 . The first, second and third conveyor belts are all equipped with a tool stop device 4c, a flow diversion mechanism 100 and an RFID read-write device 20e. Wherein the first conveyer belt 1, the second conveyer belt 2 and the third conveyer belt 3 are all roller-type conveyer belts which a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com