High borosilicate glass product girdling device

A technology of high borosilicate glass and products, applied in glass cutting devices, glass manufacturing equipment, grinding drive devices, etc., can solve the problems of easy cutting damage, inaccurate cutting, difficult multi-station cutting, etc., and achieve cutting quality. Good, improve work efficiency, improve the effect of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

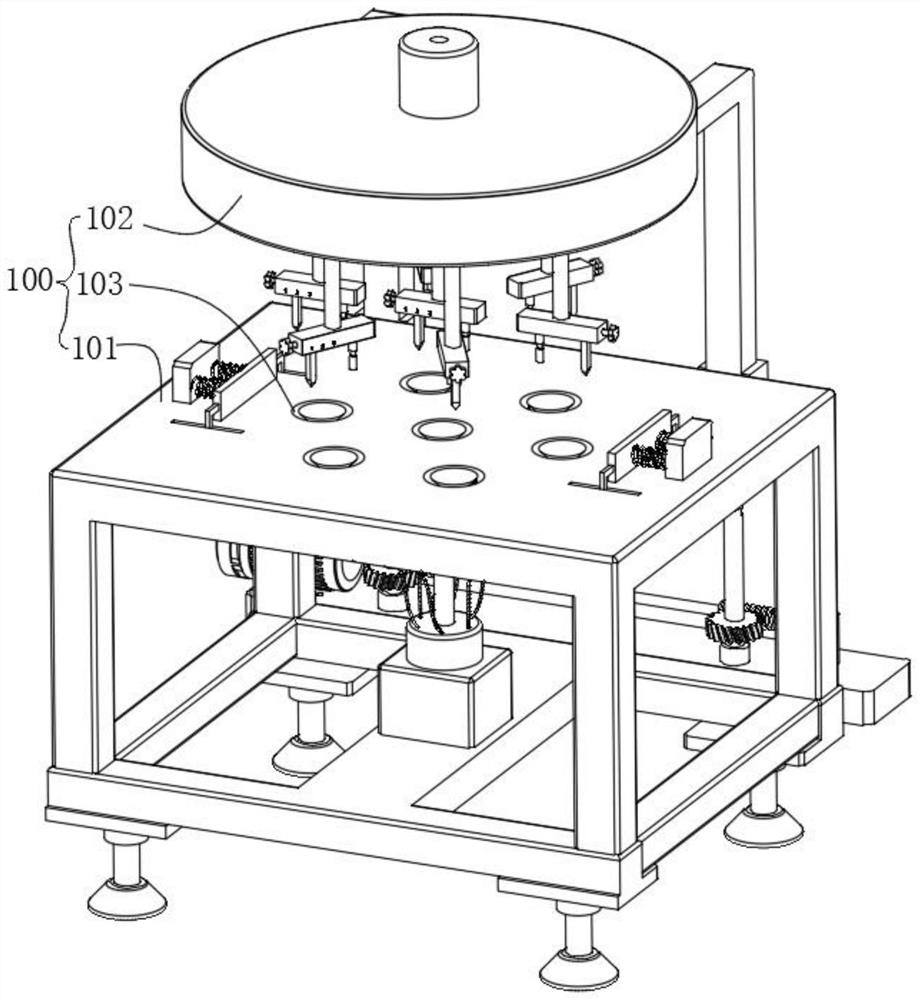

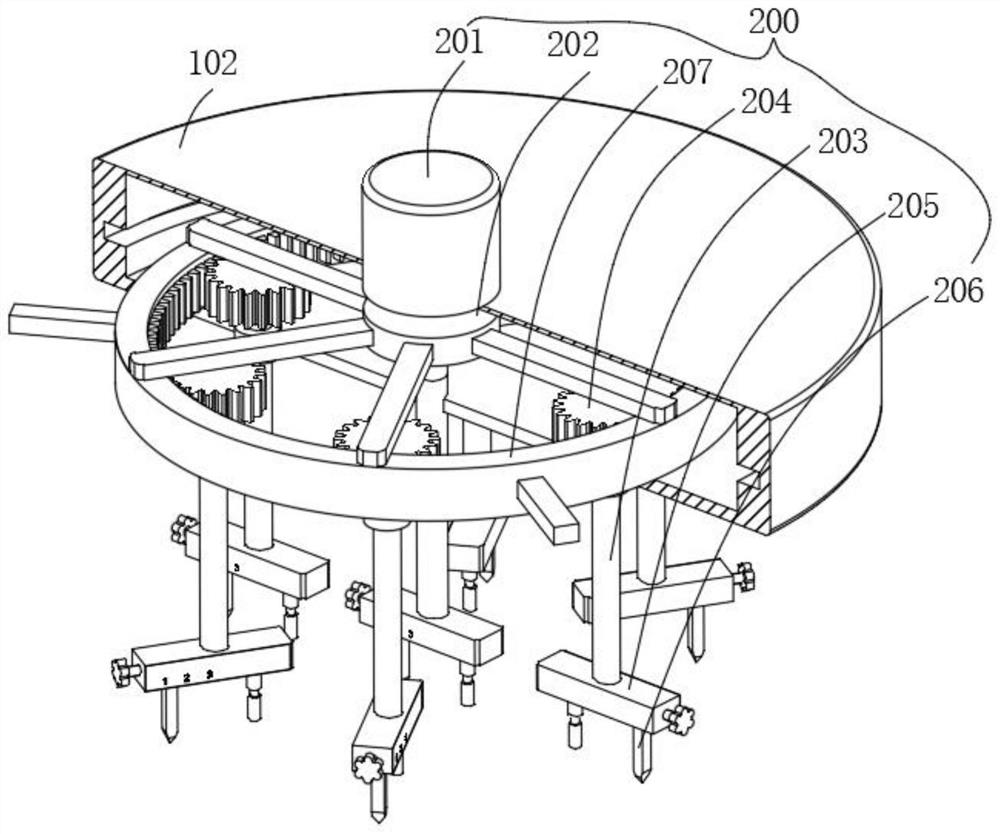

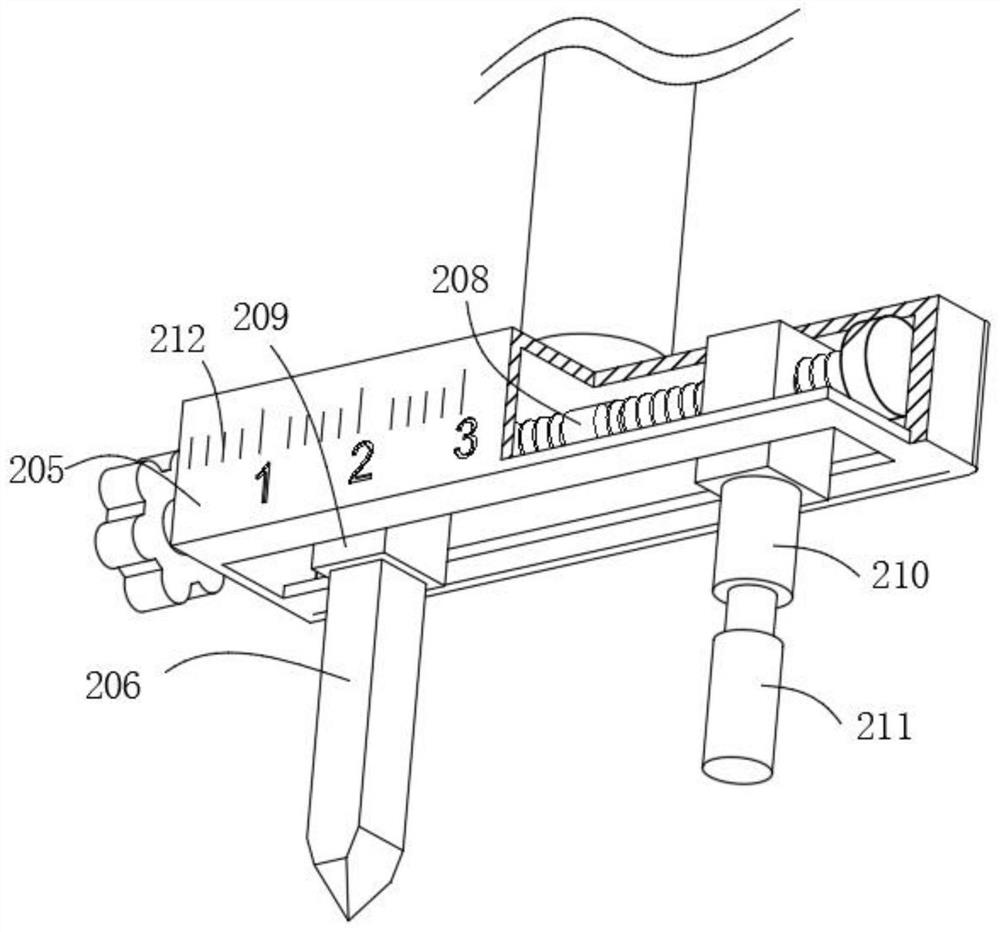

[0051] combine figure 1 , 2 As shown in and 3, the high borosilicate glass product ring cutting device provided by the present invention includes a body 100, a cutting mechanism 200, an adjustment mechanism 300, a lifting mechanism 400 and a positioning mechanism 500. The body 100 includes a workbench 101 and a workbench 101 The casing 102 above and a plurality of transmission holes 103 opened on the workbench 101, the cutting mechanism 200 includes a first motor 201 fixed on the casing 102, a transmission frame 202 fixed on the output end of the first motor 201, a fixed The gear ring 207 connected to the bottom of the transmission frame 202, the plurality of transmission shafts 203 rotatably mounted on the bottom of the housing 102, the gear 204 fixed on the top of the transmission shaft 203 and meshed with the gear ring 207, and fixed on the bottom of the transmission shaft 203 The connection box 205 at the end and the cutting knife 206 arranged at the bottom of the connect...

Embodiment 2

[0057] combine figure 2 with 5 As shown, on the basis of Embodiment 1, the adjustment mechanism 300 includes a second motor 301 installed on the workbench 101, an output shaft fixed to the output end of the second motor 301, a worm screw 302 sleeved on both sides of the output shaft, and Rotate and install the screw rod 303 on both sides of the workbench 101, the worm wheel 305 that is sleeved on the screw rod 303 and meshes with the worm screw 302 for transmission, and the connecting sleeve 304 that is suitable for sliding relative to the screw rod 303. The end of the connecting sleeve 304 is fixedly connected with the housing 102. The second motor 301 starts to drive the output shaft to rotate, the worm 302 rotates with the output shaft, the worm 302 and the worm wheel 305 are meshed for transmission, and the worm 302 drives the screw 303 to rotate through the worm wheel 305, so that the connecting sleeve 304 moves, and the housing 102 follows the connection The sleeve 304...

Embodiment 3

[0059] combine image 3 with 6 As shown, in the above embodiment, the lifting mechanism 400 includes a vacuum glass hoist 401, a suction cup arranged on the vacuum glass hoist 401, an electric push rod 402 placed on the vacuum glass hoist 401, and affixed to The connecting frame 403 at the end of the electric push rod 402 and a plurality of ejector rods 404 fixed on the connecting frame 403, the top of the ejector rod 404 is fixedly connected with the suction cup, the suction cup is located in the transmission hole 103, and the vacuum glass suction hoist 401 passes through the suction cup Suction is generated to fix the material and avoid shaking during cutting, so that the cutting quality of the material is better, and the electric push rod 402 pushes the connecting frame 403 to rise, and the ejector rod 404 rises with the vacuum glass suction hoist 401, and then the cutting can be carried out. The finished product is lifted up, which is convenient for the staff to process t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com