PBT/PET alloy material and preparation method thereof

A technology for alloy materials and raw materials, applied in the field of PBT/PET alloy materials and their preparation, can solve problems such as poor thermal deformation temperature stability, and achieve the effects of easy operation and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

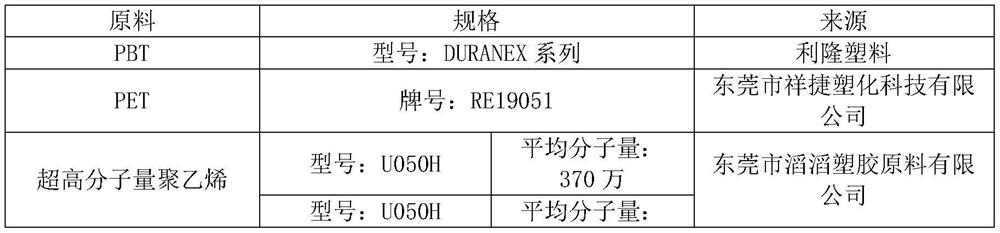

Method used

Image

Examples

Embodiment 1

[0037] A PBT / PET alloy material, comprising the following preparation steps:

[0038] S1. Dry PBT and PET at 130°C for 5h for use, and dry ultra-high molecular weight polyethylene and polyamide resin at 90°C for 40min for use;

[0039] S2, mix the dried 3kg PBT, 5kg PET, 0.4kg ultra-high molecular weight polyethylene, 0.8kg polyamide resin, 0.03kg nucleating agent and 0.1kg acrylate at a stirring speed of 300r / min for 40min to make the mixture , and then the mixture was extruded at 285 ° C to obtain PBT / PET alloy material;

[0040] The average molecular weight of the ultra-high molecular weight polyethylene used is 7 million; the polyamide resin used is a copolymer polyamide resin with a brand name of CM4000; the nucleating agent used is talcum powder; the acrylate used is ethyl acrylate.

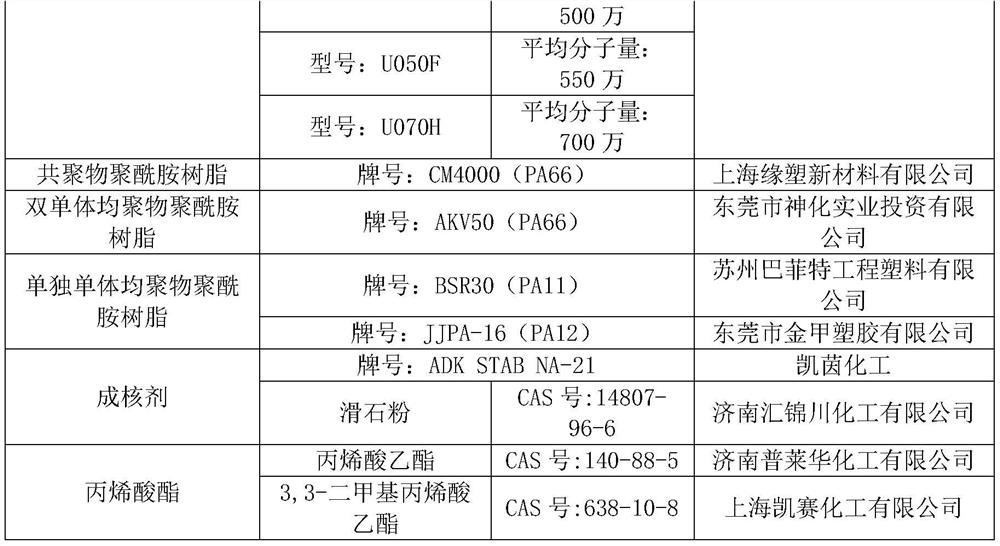

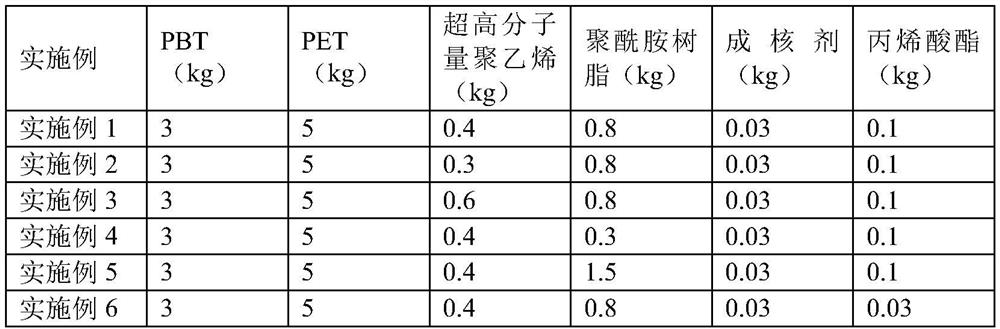

Embodiment 2-9

[0042] Examples 2-9 are all based on Example 1, and the only difference from Example 1 is that the consumption of each raw material is different, as shown in Table 2 for details.

[0043] Table 2. Consumption of each raw material in Examples 1-9

[0044]

[0045]

Embodiment 10

[0047] Example 10 is based on Example 9, and the only difference from Example 9 is that ethyl acrylate is replaced by ethyl 3,3-dimethacrylate of the same mass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com