A medium and high temperature mixed molten salt heat storage system with high latent heat and preparation method

A mixed molten salt, medium and high temperature technology, applied in chemical instruments and methods, heat exchange materials, etc., can solve the problem of narrow temperature range, and achieve the effect of low cost, low viscosity and low equipment performance requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

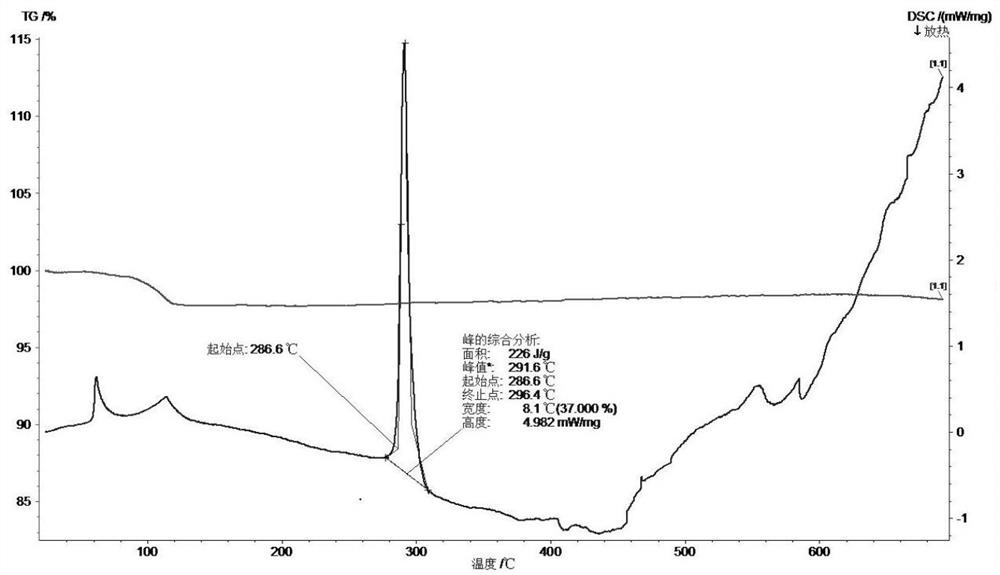

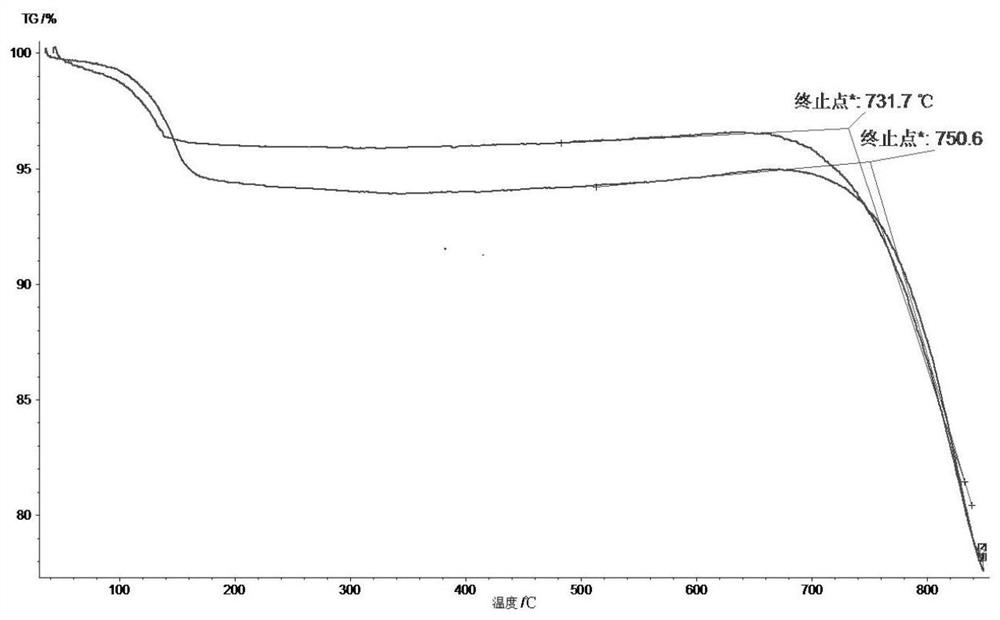

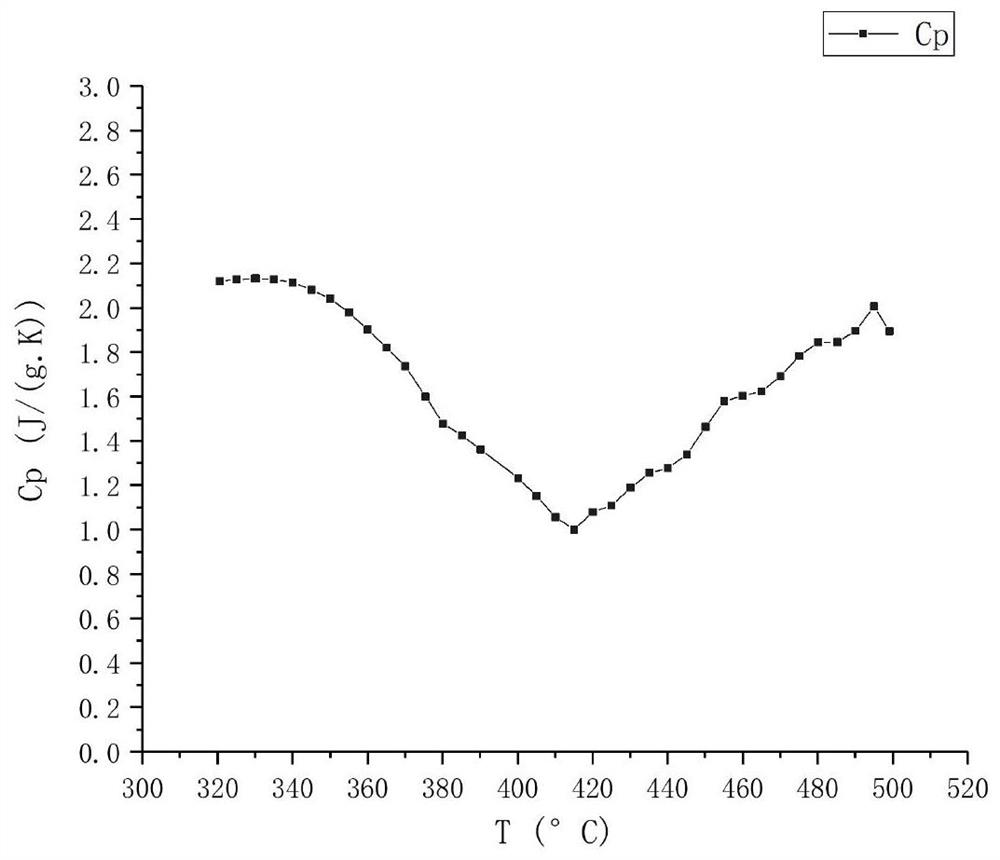

[0025] A ternary nitric acid molten salt system and a preparation method comprise the following steps.

[0026] S1. Mix 60.00-70.00wt.% sodium nitrate, 25.00-35.00wt.% sodium hydroxide and 5.00-10.00wt.% sodium carbonate in a crucible to obtain a mixture.

[0027] S2. Put the mixture into a muffle furnace for heating, set the heating rate of the muffle furnace to 10°C / min, set the holding temperature of the muffle furnace to 500°C, and set the heat preservation time of the melt in the muffle furnace to 3h.

[0028] S3. Heating and insulating the melt in a muffle furnace to obtain the mixed molten salt solid;

[0029] S4. Take out the mixed molten salt solid in the muffle furnace, place it in a drying box to cool naturally, put the cooled mixed molten salt into the ultrafine pulverizer for pulverization, and obtain 20-200 mesh solids. Said mixed molten salt powder;

[0030] S5. Place the pulverized mixed molten salt powder in a drying oven for constant temperature drying trea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com