Heat conduction structure for heat dissipation of PE plate

A heat conduction structure and plate technology, applied in indirect heat exchangers, heat exchange equipment, heat exchanger shells, etc., can solve the problems of poor air permeability, unfavorable ventilation and heat dissipation, and decreased heat resistance, so as to improve heat conduction, improve mechanical strength, The effect of improving the stability of the installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

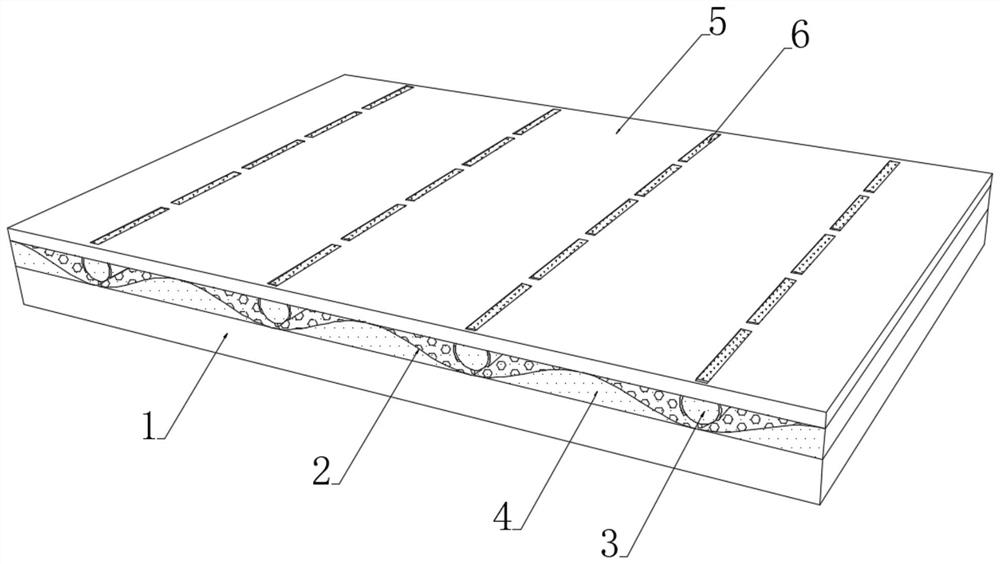

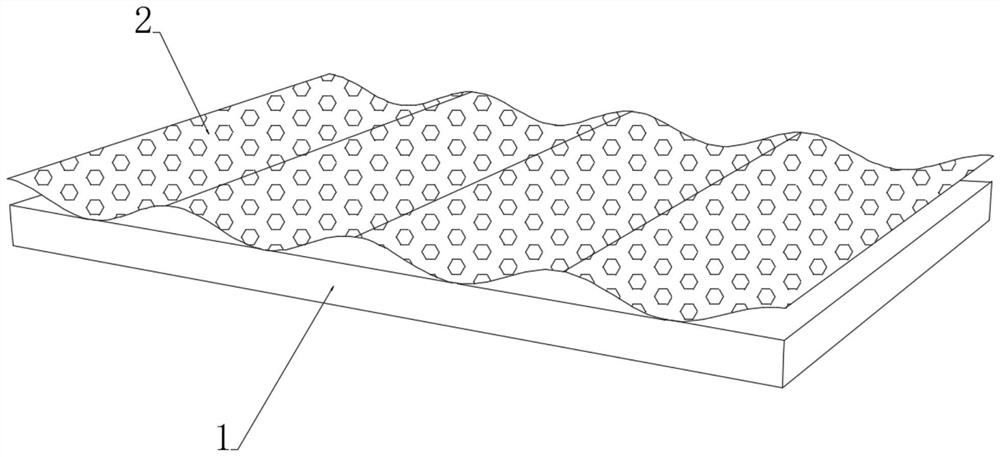

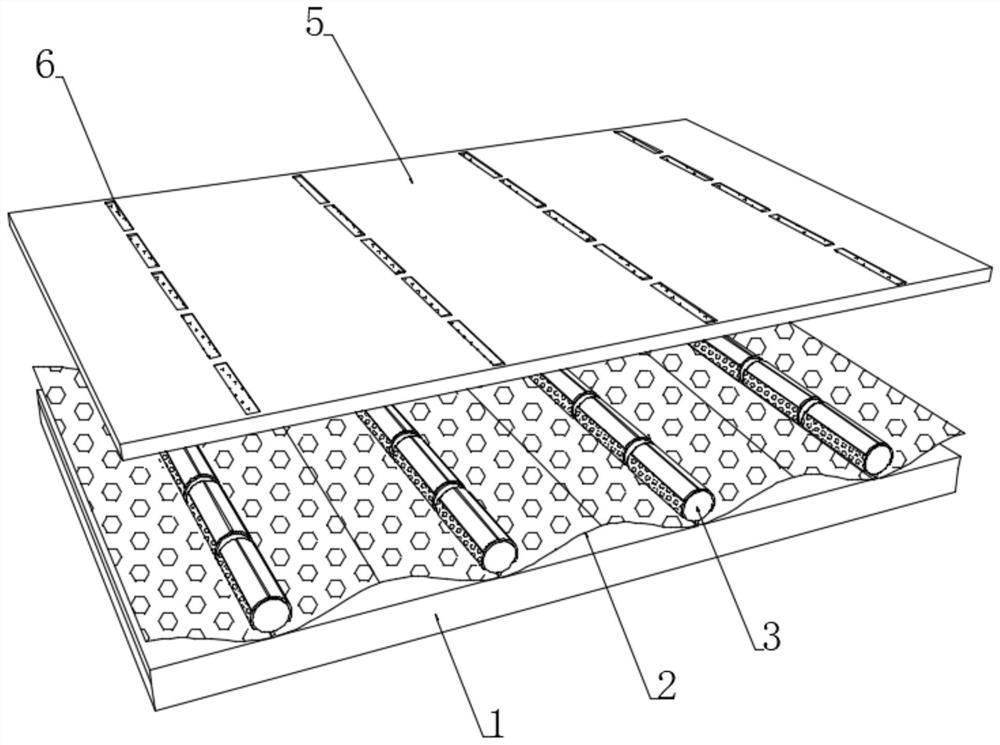

[0043] see Figure 1-3 , a heat conduction structure for PE sheet heat dissipation, including a honeycomb heat conduction sheet 2 attached to a PE sheet 1, a plurality of heat conduction columns 3 are distributed along the horizontal direction on the honeycomb heat conduction sheet 2, and the honeycomb heat conduction sheet 2 is in the shape of a wavy surface structure, a plurality of heat conduction columns 3 are evenly distributed on the concave surface of the honeycomb heat conduction sheet 2, and the honeycomb heat conduction sheet 2 is arranged in a wave shape, which is beneficial to improve the connection area between it and the heat conduction column 3 on the one hand, and on the other hand the heat conduction column 3 Located on its concave surface, it effectively improves the installation stability of the honeycomb heat conduction sheet 2. The honeycomb heat conduction sheet 2 is made of graphite fiber material. There are a number of honeycomb pores on the honeycomb he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com