Comprehensive test method for SiC wafer and epitaxial layer structure thereof

A comprehensive testing and epitaxial layer technology, applied in optical testing flaws/defects, measuring devices, material analysis by optical means, etc., can solve the problems of use and difference, improve economic efficiency, reduce cost input, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

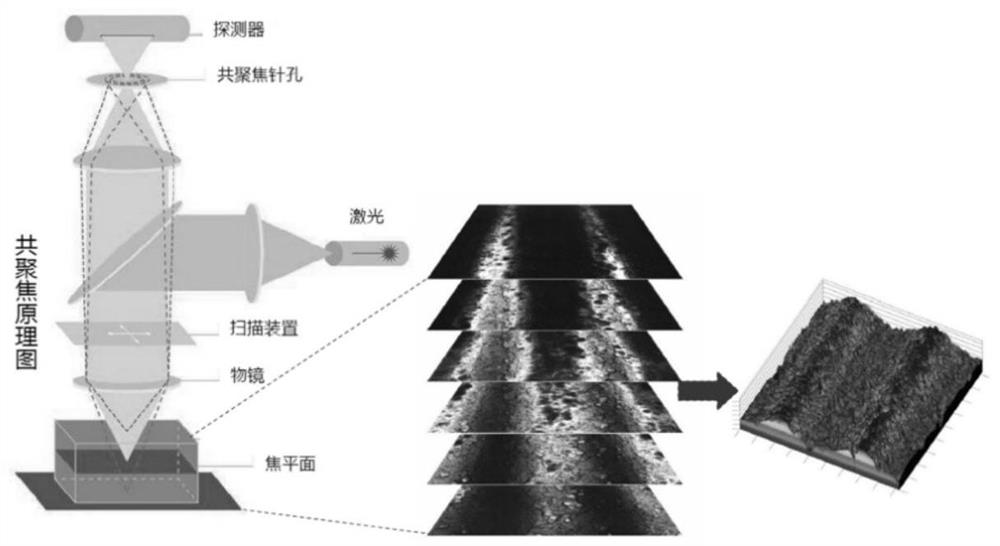

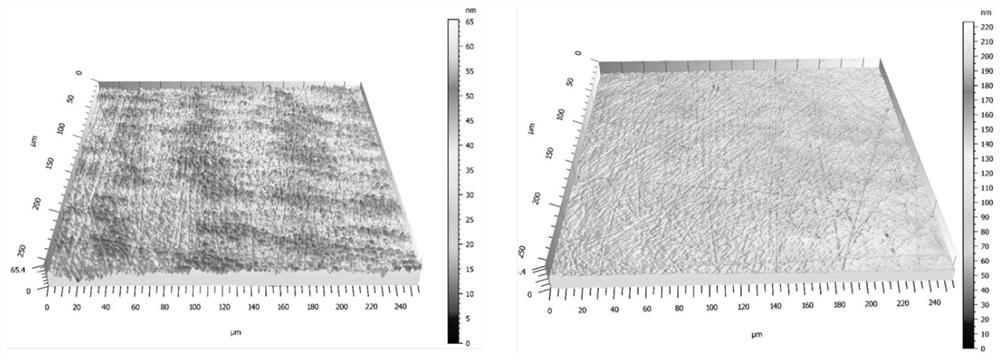

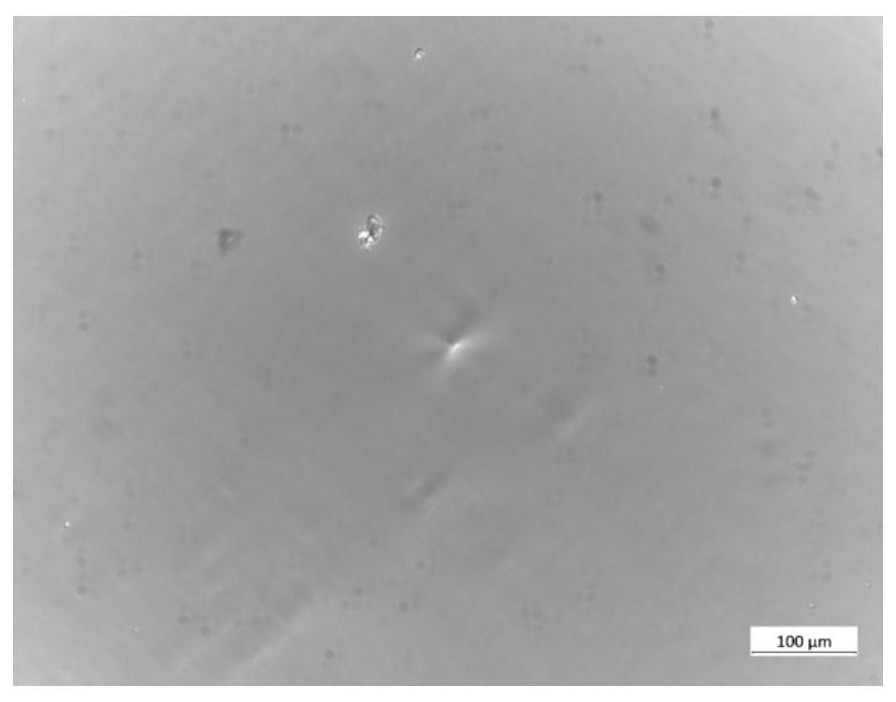

Method used

Image

Examples

Embodiment Construction

[0038] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the embodiments of the present invention. Apparently, the described embodiments are only some of the embodiments of the present invention, not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

[0039] Explanation of terms:

[0040] i. Micropipe defect: A crystallization defect in SiC wafers, which belongs to the category of line defects, physical holes with micron-scale diameters, and threading screw dislocations with large Burgers vectors. It is a unique defect in SiC crystals, which can extend for a long distance in the crystal, even throughout the entire crystal, and has a great impact on the performance and yield of SiC devices.

[0041] ii. Epitaxial layer: Si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com