High-reliability packaging structure and packaging method for microwave piece cover plate

A technology of packaging structure and packaging method, which is applied in the directions of electrical components, electric solid-state devices, semiconductor devices, etc., can solve the problems of high-reliability packaging structure and method of unseen microwave components, unseen encapsulation cover plate structure and packaging method, etc. The realization of micro-assembly promotes, enhances the integration density, and achieves the effect of highly reliable integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

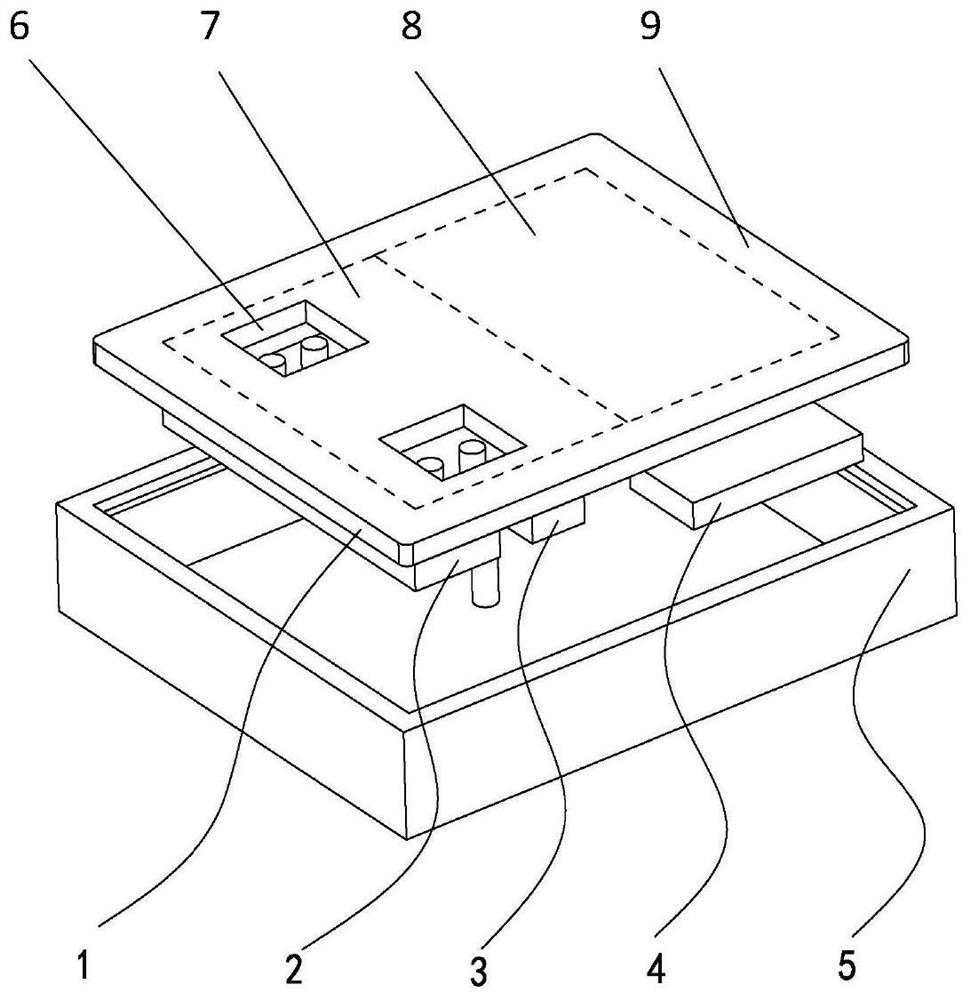

[0035] This embodiment discloses a highly reliable packaging structure for a cover plate 1 of microwave components, including a cover plate 1 and a box body 5. The cover plate 1 includes an external output interface 6, and the middle part of the cover plate 1 includes chips and ceramics. The circuit substrate assembly area 7 also includes an organic circuit substrate assembly area 8, and a sealing connection portion 9 is arranged at the edge of the cover plate 1, and the sealing connection portion 9 extends along the edge of the cover plate 1 and forms a closed ring; the entire cover plate in this example It is prepared by integrated powder metallurgy of gradient silicon-aluminum materials. The chip and ceramic circuit substrate assembly area 7 adopts AlSi50 with a thermal expansion coefficient of 11ppm (Al accounts for 50%, and Si accounts for 50%). The thermal expansion coefficient of the organic circuit substrate assembly area 8 AlSi35 (Al accounts for 65%, Si accounts for 3...

Embodiment 2

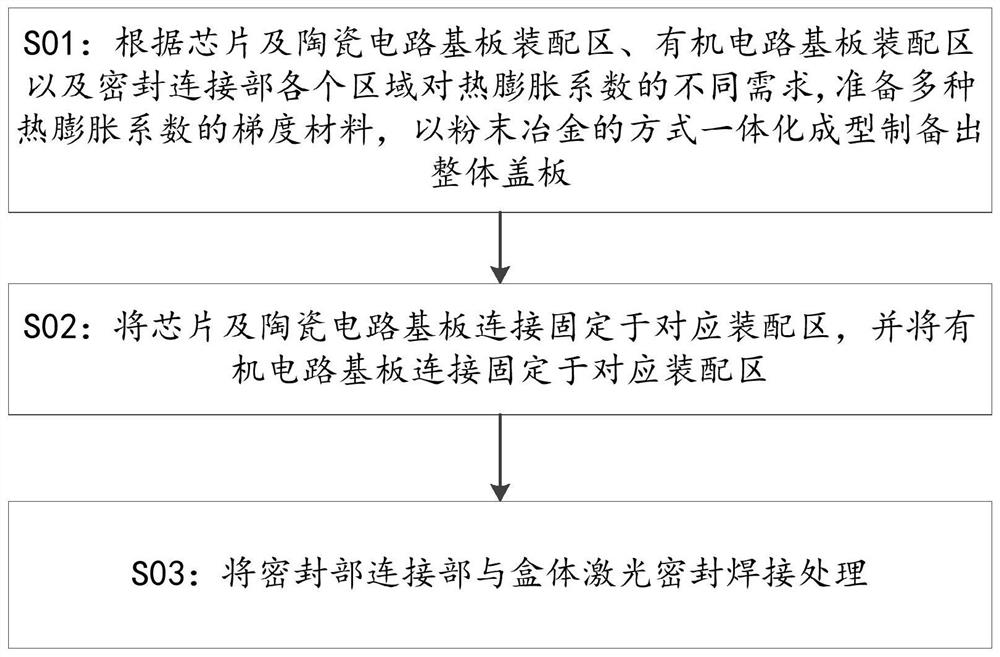

[0049] The content of the above-mentioned embodiment 1 discloses the encapsulation structure, and this embodiment discloses the corresponding encapsulation method for realizing the encapsulation structure, which is now specifically explained:

[0050] A highly reliable packaging method for a cover plate of a microwave component, used to realize the packaging of the above packaging structure, comprising:

[0051] S01: According to the different requirements for the thermal expansion coefficient of the chip and ceramic circuit substrate assembly area, the organic circuit substrate assembly area, and the sealing connection area, prepare a variety of gradient materials with thermal expansion coefficients, and prepare the integral cover by integral molding in the form of powder metallurgy plate;

[0052] S02: Connect and fix the chip and the ceramic circuit substrate in the corresponding assembly area, and connect and fix the organic circuit substrate in the corresponding assembly ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com