Display panel and manufacturing method thereof

A technology for a display panel and a manufacturing method, which is applied in the manufacturing of semiconductor/solid-state devices, electrical components, and electrical solid-state devices, etc., can solve problems such as mutual crosstalk, and achieve the effect of ensuring normal operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

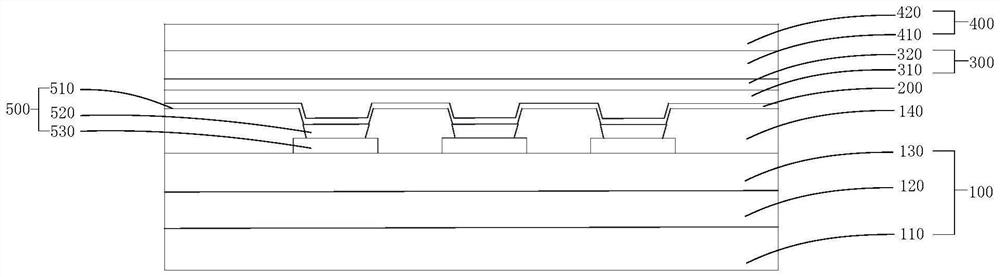

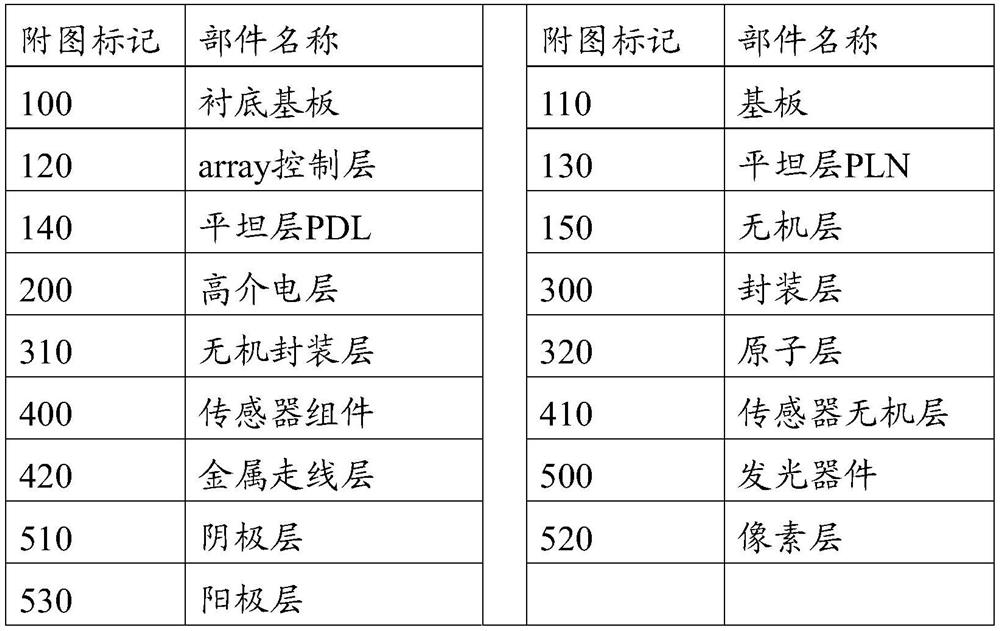

[0042] The first embodiment of the present application discloses a display panel, which includes from bottom to top: a base substrate 100, a light emitting device 500, an encapsulation layer 300, and a sensor assembly 400, and the encapsulation layer 300 passes between the light emitting device 500 and the sensor assembly 400 Separated, wherein both the light emitting device 500 and the sensor component 400 are energized to work, and when the encapsulation layer 300 is thin, the capacitance of the encapsulation layer 300 is low, and mutual crosstalk between the light emitting device 500 and the sensor component 400 is prone to occur, resulting in abnormal light emission or sensor failure occurs.

[0043] In view of this, the display panel in this embodiment further includes: a high dielectric layer 200, the high dielectric layer 200 is arranged between the encapsulation layer 300 and the light emitting device 500, the high dielectric layer 200 has a relatively high dielectric p...

Embodiment 2

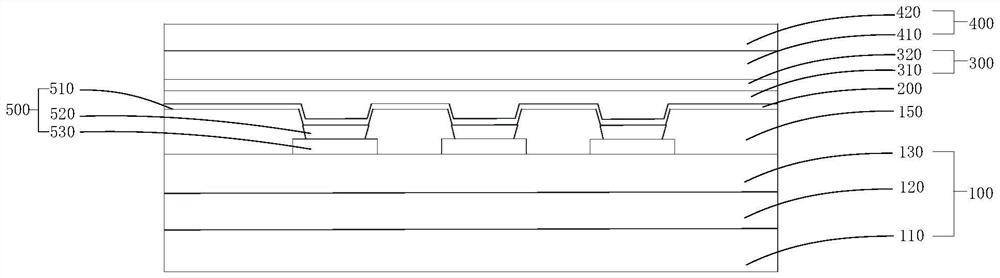

[0049] The second embodiment of the present application relates to a display panel, which is generally the same as the display panel in the first embodiment. The control layer 120, the flat layer PLN130 disposed on the array control layer 120, and the inorganic layer 150 disposed on the flat layer PLN130. In this embodiment, the flat layer PDL140 in the first embodiment is replaced by the inorganic layer 150. The inorganic layer 150 It is disposed on the flat layer PLN130 , and the light emitting device 500 is disposed in the inorganic layer 150 . The inorganic layer 150 can further strengthen the water and oxygen barrier capability of the side of the pixel layer 520 to protect the light emitting device 500 .

Embodiment 3

[0051] The third embodiment of the present application discloses a method for manufacturing a display substrate, which can be used to manufacture the display substrate in the first embodiment or the second embodiment, including the following steps:

[0052] A base substrate is provided; the base substrate includes: a substrate, an array control layer disposed on the substrate, a flat layer PLN disposed on the array control layer, and a flat layer PDL disposed on the flat layer PLN; wherein the flat layer can be formed by the PDL replaced by an inorganic layer.

[0053] disposing a light emitting device on the substrate;

[0054] Deposit a high dielectric layer on the light-emitting component; the high dielectric layer is Al 2 o 3 Film layer, ZrO 2 film or HfO 2 One of the membrane layers. In this embodiment, the PVD method can be used to deposit a certain thickness of Al 2 o 3 , forming Al 2 o 3 film layer, deposited directly on the cathode layer.

[0055] An encapsu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com