Flame-proof three-phase asynchronous motor

A three-phase asynchronous motor technology, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of untimely heat discharge and decreased working efficiency of three-phase asynchronous motors, so as to improve work efficiency, reduce temperature, increase The effect of the cooling area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

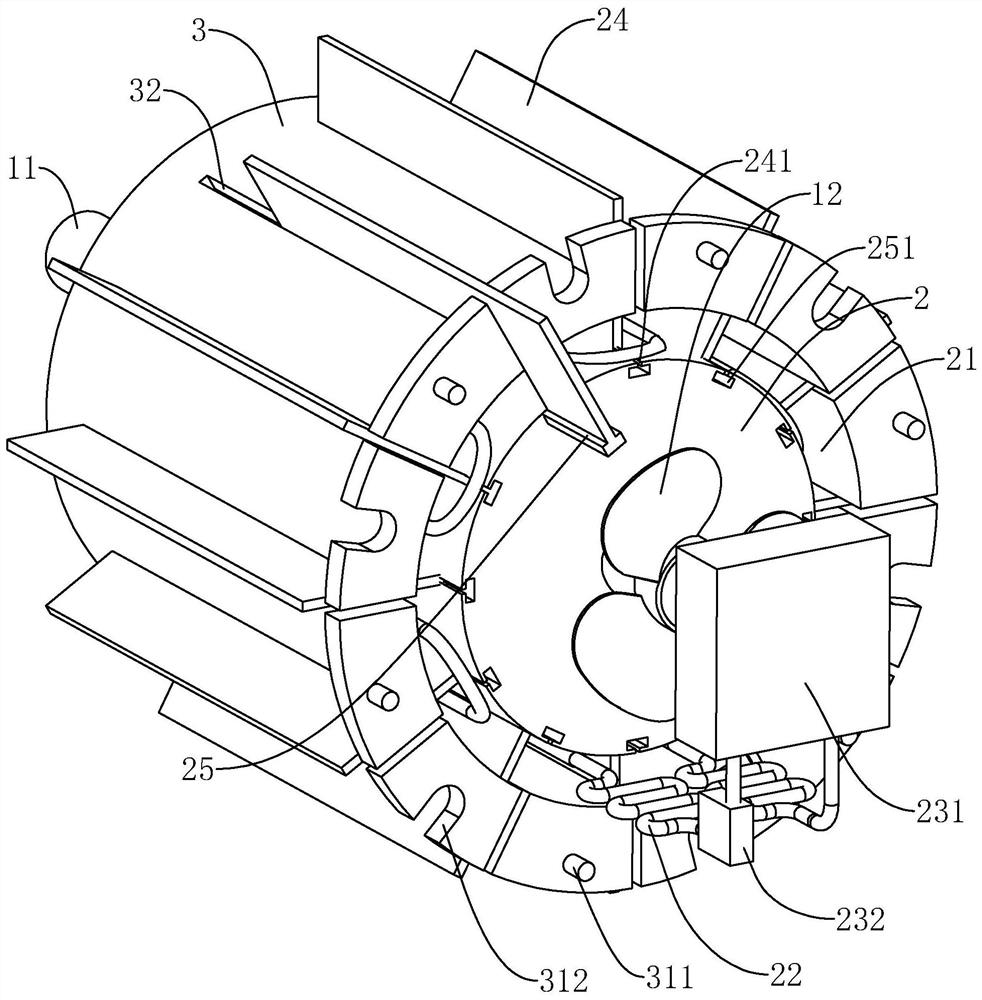

[0033] The following is attached Figure 1-3 The application is described in further detail.

[0034] The embodiment of the present application discloses a flameproof three-phase asynchronous motor.

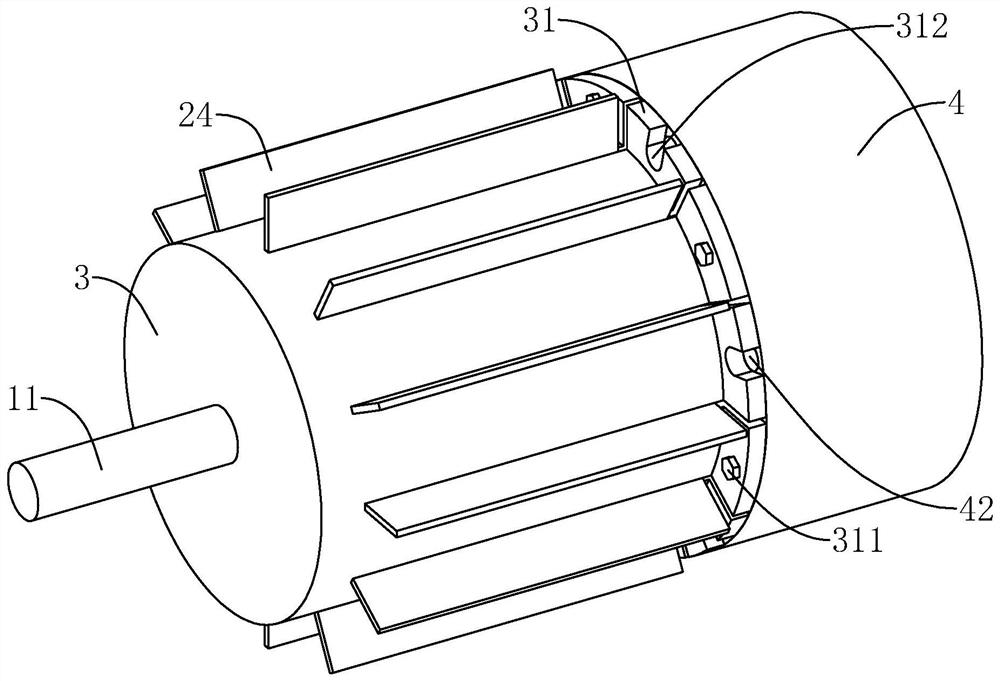

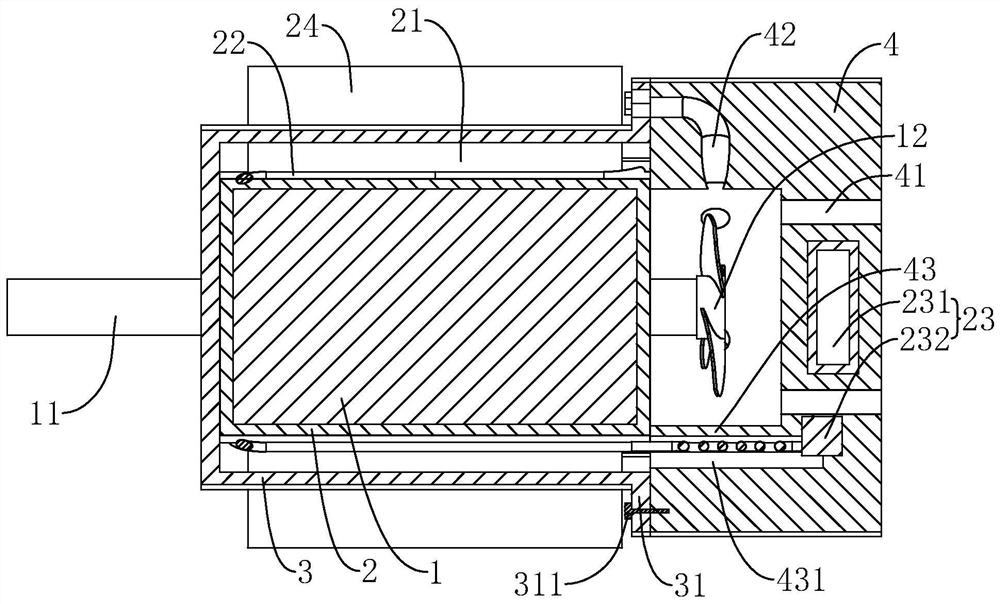

[0035] refer to figure 1 and figure 2 A flameproof three-phase asynchronous motor includes a body 1, an inner shell 2 sealed and fixedly connected to the body 1, an outer shell 3 covering the inner shell 2, and the outer shell 3 and the inner shell 2 are also fixedly connected.

[0036] refer to figure 2, and the body 1 includes a rotating shaft 11, the two ends of the rotating shaft 11 extend out of the inner shell 2 and the outer shell 3, one end of the outer shell 3 is detachably connected to the rear end cover 4, and one end of the rotating shaft 11 extending into the rear end cover 4 is coaxially connected to a The fan 12, the diameter of the fan 12 is the same as the diameter of the rear end cover 4, the rear end cover 4 is provided with a number of air inlets 41 on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com