Anticoagulant coating and preparation method thereof

An anti-coagulation and coating technology, applied in the field of anti-coagulation coating and its preparation, can solve the problems of reduced anti-coagulation effect, restricted movement, monopoly, etc., and achieves improved blood stability, increased stability, and good application. Potential effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

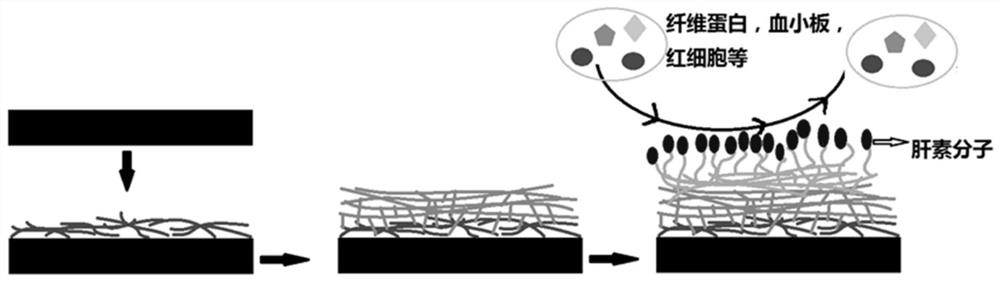

[0051] An embodiment of the anticoagulant coating of the present invention, the anticoagulant coating described in this embodiment is polydopamine-polylysine-(No. 1 heparin-protein complex) coating, the structure is as attached figure 1 As shown, it includes substrate 1, polydopamine coating 2, polyamino compound connecting layer 3, and heparin-protein functional layer 4 from bottom to top, and the layers are connected by covalent bonds; the preparation process is as shown in the attached figure 2 As shown, the details are as follows:

[0052] Step 1. Weigh 500 mg of dopamine hydrochloride and dissolve it in 500 ml of deionized water, adjust the pH to 8.5, then add 500 mg of sodium periodate to dissolve, and prepare coating solution 1. Use a peristaltic pump to suck the coating liquid 1 into the circulating coating system, use the PVC pipe to be coated as the circulation channel pipeline, and put the parts to be coated of other materials to be coated into the liquid accumulat...

Embodiment 2

[0057] An embodiment of the anticoagulant coating of the present invention, the anticoagulant coating described in this embodiment is polydopamine-polyethyleneimine-(No. 1 heparin-protein complex) coating, and the structure is as attached figure 1 As shown, it includes substrate 1, polydopamine coating 2, polyamino compound connecting layer 3, and heparin-protein functional layer 4 from bottom to top, and the layers are connected by covalent bonds; the preparation process is as shown in the attached figure 2 As shown, the details are as follows:

[0058] Step 1. Weigh 50 mg of dopamine hydrochloride and dissolve it in 500 ml of deionized water, adjust the pH to 7, then add 50 mg of sodium periodate to dissolve, and prepare coating solution 1. Use a peristaltic pump to suck the coating liquid 1 into the circulating coating system, use the PVC pipe to be coated as the circulation channel pipeline, and put the parts to be coated of other materials to be coated into the liquid ac...

Embodiment 3

[0063] An embodiment of the anticoagulant coating of the present invention, the anticoagulant coating in this embodiment is polydopamine-polyethyleneimine-(No. 2 heparin-protein complex), and the structure is as attached figure 1 As shown, it includes substrate 1, polydopamine coating 2, polyamino compound connecting layer 3, and heparin-protein functional layer 4 from bottom to top, and the layers are connected by covalent bonds; the preparation process is as shown in the attached figure 2 As shown, the details are as follows:

[0064] Step 1. Weigh 5000 mg of dopamine hydrochloride and dissolve it in 500 ml of deionized water, adjust the pH to 10, then add 5000 mg of sodium periodate to dissolve, and prepare coating solution 1. Use a peristaltic pump to suck the coating liquid 1 into the circulating coating system, use the PVC pipe to be coated as the circulation channel pipeline, and put the parts to be coated of other materials to be coated into the liquid accumulation bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com