Devolatilization device

A devolatilizer, one-to-one correspondence technology, applied in the field of devolatilizer, can solve the problems such as difficult transformation, achieve enhanced effect, good volatilization effect, and increase volatilization interface area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

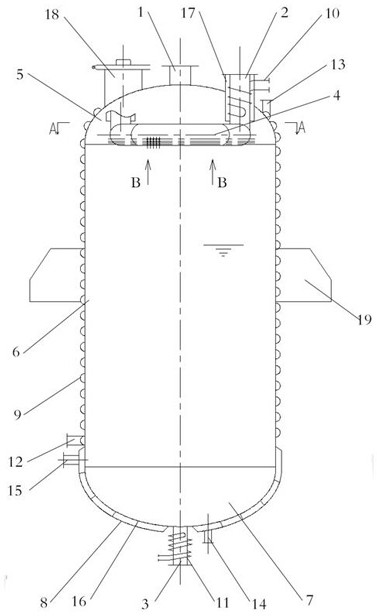

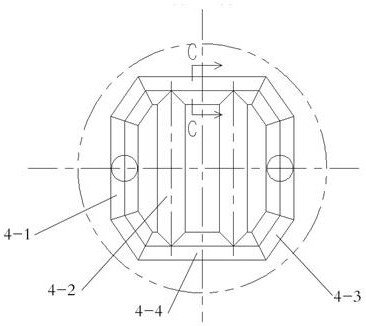

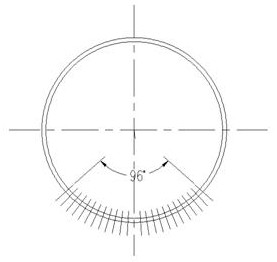

[0030] Such as Figure 1-7 As shown, a devolatilizer, the devolatilizer includes a devolatilizer body, the top of the devolatilizer body is provided with a gas phase outlet 1, the upper part is provided with a material inlet 2, and the bottom is provided with a material outlet 3. A material distributor 4 is installed in the device body, and the material distributor 4 is located on the upper part of the devolatilizer body; there are two material inlets 2; the material distributor 4 is spliced by a number of distribution pipes, in the shape of "mesh", The material distributor 4 is placed horizontally, and its upper side is provided with two feed ports, the two feed ports are symmetrical about the central axis of the material distributor 4, and its lower side is provided with a number of discharge ports; the material inlet 2 are connected to the feed inlet one by one; the devolatizer body is also equipped with a heat preservation device; the material inlet 2, the material outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com