Processing technology and application method of anchor rod capable of improving anchoring performance

A processing technology and technology for anchoring rods, which are used in the installation of anchor rods, earth-moving drilling, mining equipment, etc., which can solve the problems of weakening of the yield strength and tensile strength of anchor rods, high processing and construction costs, and reduced anchoring efficiency of anchor rods, etc. To improve the conversion efficiency of preload force, increase the anchoring effect, and achieve the effect of stable support of the roadway

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

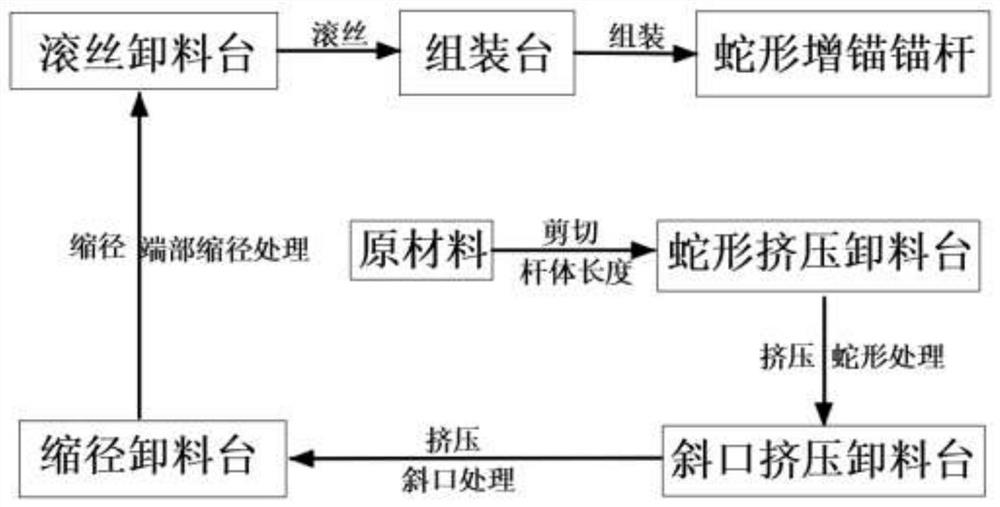

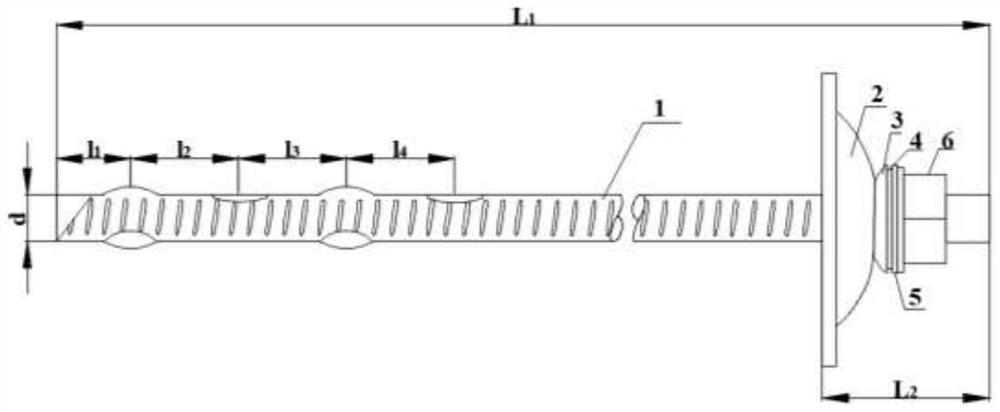

[0039] In this embodiment, a processing technology of an anchor rod that can improve anchoring efficiency is mainly characterized in that it includes an extrusion process, and in the extrusion process, a specially designed snake is formed at one end of the anchor rod body 1 (inner rod) through standard extrusion. Shape mouth, when using rebar as raw material, it can be summarized as the following steps:

[0040] (1) Use a shearing machine to cut the raw rebar into the required length.

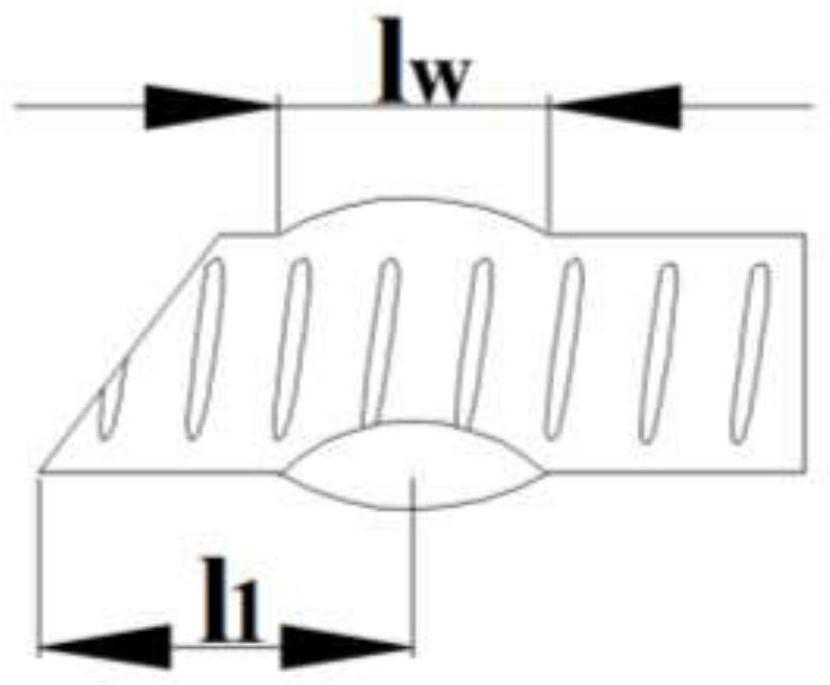

[0041] (2) Select the serpentine groove extrusion die according to the diameter of the rebar, and perform standard extrusion to generate the serpentine mouth.

[0042] (3) Carry out secondary shearing and pressing, use a shearing mold, adjust the shearing angle of the shearing mold, and perform end bevel processing.

[0043] (4) Use the reduction die to reduce the standard diameter of the qualified rebar with the end bevel treatment.

[0044] (5) Perform standard rolling on the thread rolling...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com