Preparation method of graphite intercalation compound negative electrode material suitable for fast-charging lithium ion battery and product and application thereof

A lithium ion battery, interlayer compound technology, applied in battery electrodes, graphite, negative electrodes, etc., can solve the problems of shortened lithium ion conduction paths, poor high-rate performance, and low negative energy density, and achieve smooth ion transmission channels. , the effect of low cost of raw materials and few preparation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A preparation method for a graphite intercalation compound negative electrode material suitable for fast-charging lithium-ion batteries, specifically comprising the following steps:

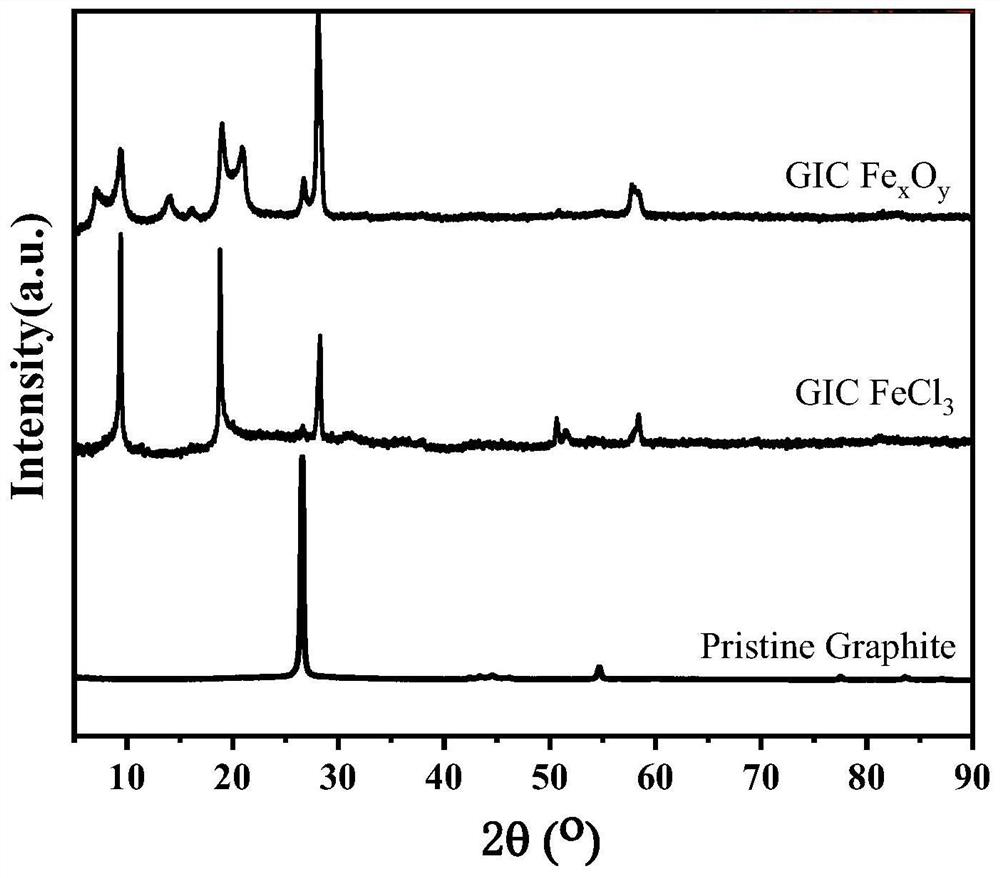

[0036] (1) Evenly mix 300-mesh flake graphite and anhydrous ferric chloride at a mass ratio of 1:5, seal it in a vacuum reactor, raise the temperature to 307°C at a rate of 5°C / min, keep it warm for 12 hours, and cool with the furnace , to obtain the intermediate product of the interlayer compound;

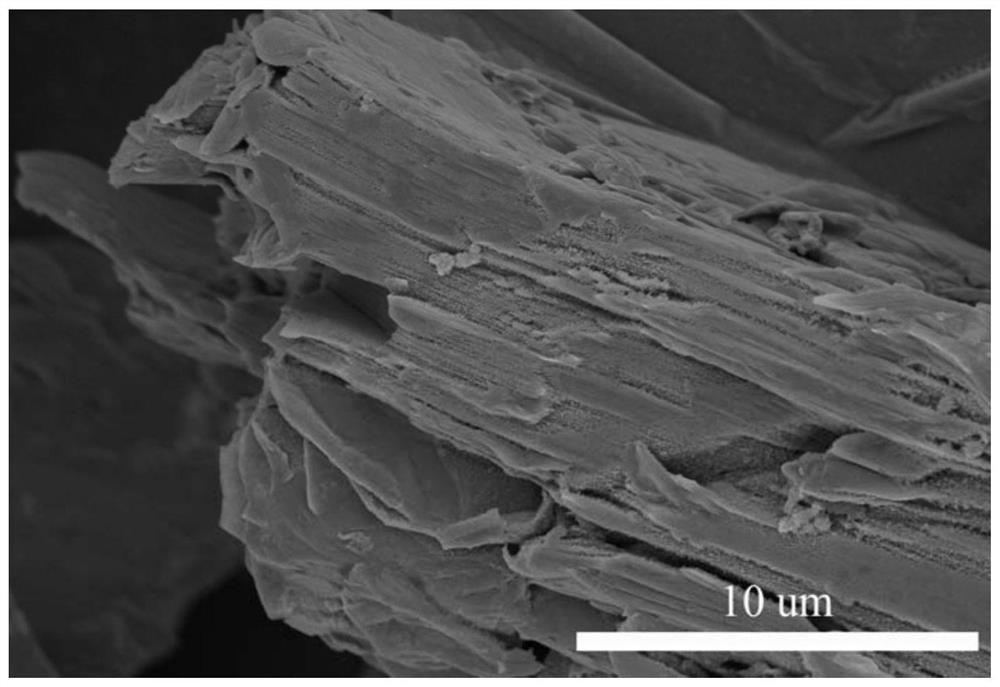

[0037] (2) Take out the intermediate product of the interlayer compound, add a sufficient amount) of 0.1M NaOH solution (the molar ratio of NaOH to anhydrous ferric chloride for preparing the intermediate product of the interlayer compound is greater than 1), ultrasonicate the solution for 30min, 300 meshes of graphite interlayer compound (GIC) were obtained, and the product was washed with deionized water several times, separated by suction filtration, and dried in an oven at 80° C. for 12 ho...

Embodiment 2

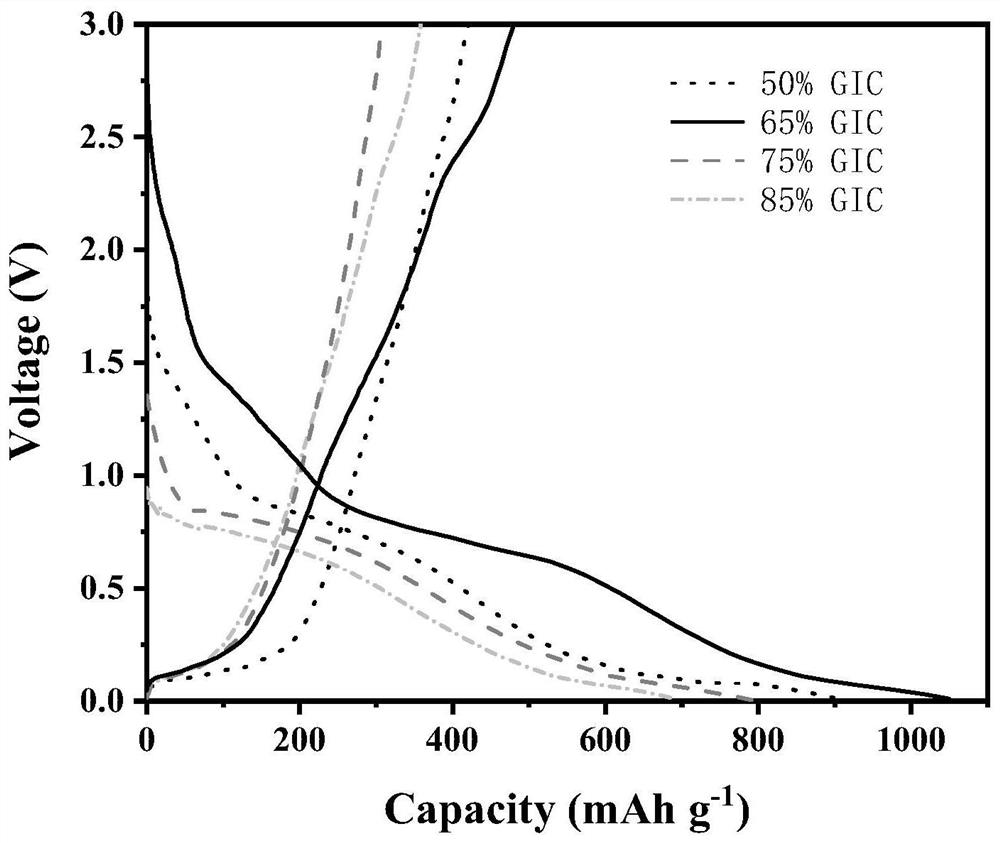

[0041] The preparation method of the graphite intercalation compound negative electrode material suitable for fast-charging lithium-ion batteries provided by this embodiment, except that the mass ratio of graphite intercalation compound and graphite flakes in step (3) is 0.65:0.35, the remaining steps and implementation Example 1 is the same.

Embodiment 3

[0043] The preparation method of the graphite intercalation compound negative electrode material suitable for fast-charging lithium-ion batteries provided by this embodiment, except that the mass ratio of graphite intercalation compound and graphite flakes in step (3) is 0.75:0.25, the remaining steps and implementation Example 1 is the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com