High-temperature and high-pressure sulfur deposition microscopic seepage visualization experiment device and method

A high-temperature, high-pressure, microscopic seepage technology, applied in the field of oil and gas reservoir development research, can solve the problems of uncontrollable heating, blockage of natural gas seepage channels, control of pressure and flow rate during seepage process, and inaccurate detection. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

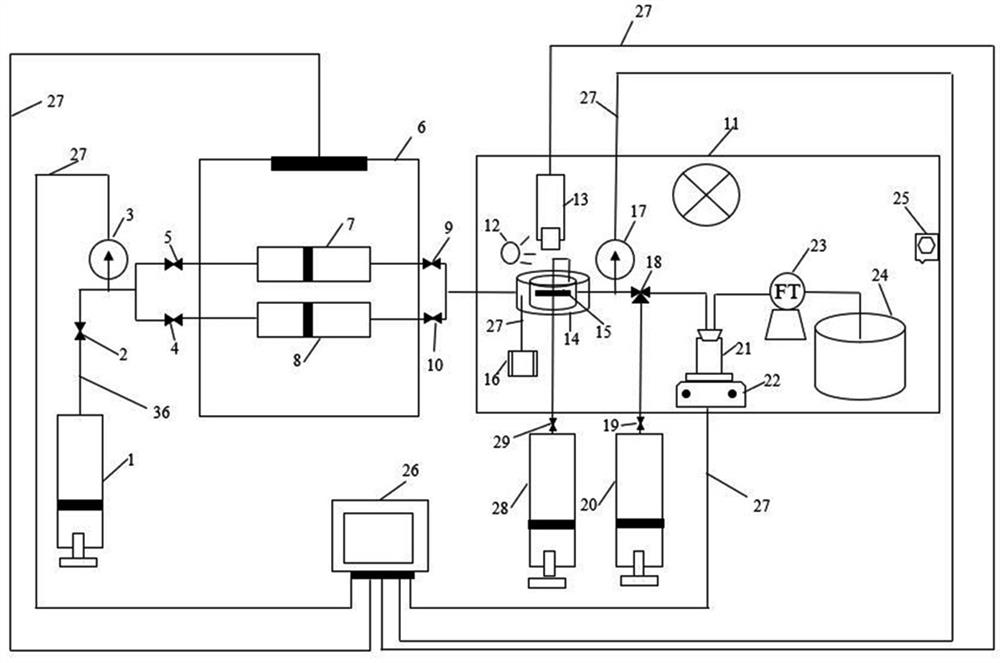

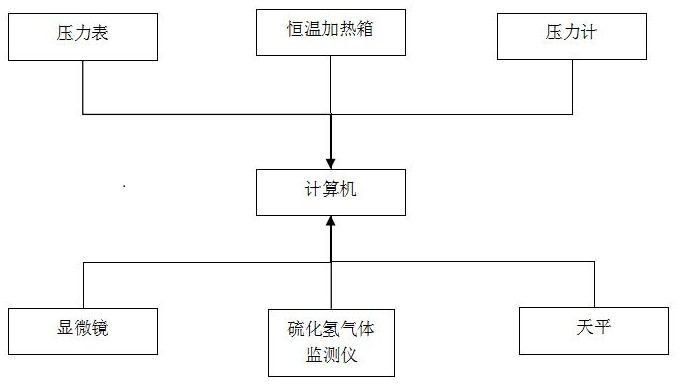

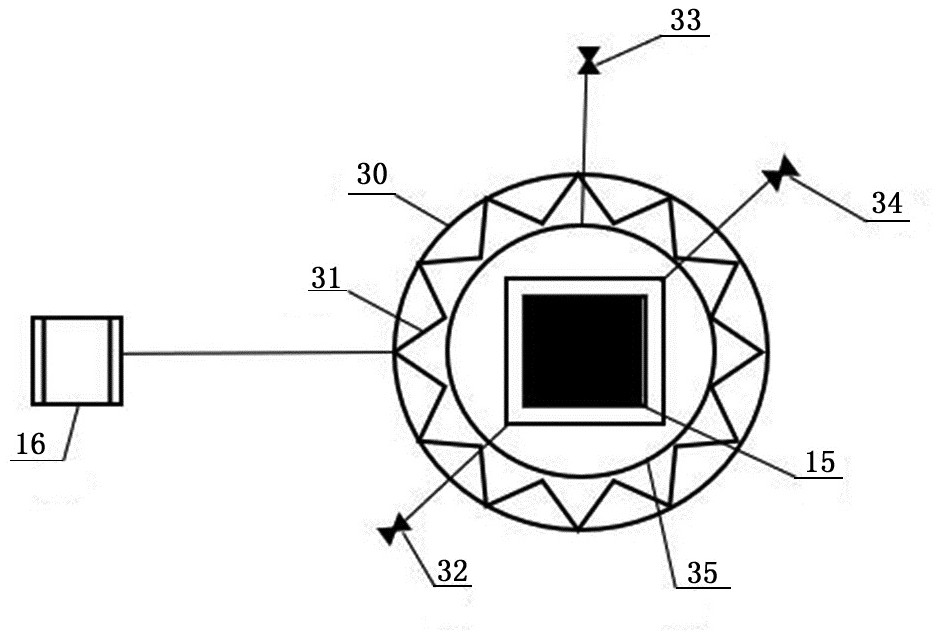

[0031] In this example, if figure 1 with figure 2As shown, a high-temperature and high-pressure sulfur deposition microscopic visual seepage experimental device is composed of an injection system, a high-temperature and high-pressure visible kettle 14, a pressure supply system, a data acquisition and analysis system, a fluid recovery system, and an injection branch pipe 36; the injection system includes ISCo Micro injection pump 1, intermediate container, constant temperature heating box 6 and pressure gauge 3, the intermediate container is set in the constant temperature heating box 6, ISCo micro injection pump 1 is connected with the intermediate container, and pressure gauge 3 is set between the ISCo micro injection pump 1 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com