Method for preparing dried sea cucumber by combined drying

A combined drying and sea cucumber technology, applied in the direction of food drying, dry preservation of meat/fish, food ingredients as antimicrobial preservation, etc., to achieve the effects of improving drying efficiency and quality, good viscoelasticity, and good texture characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

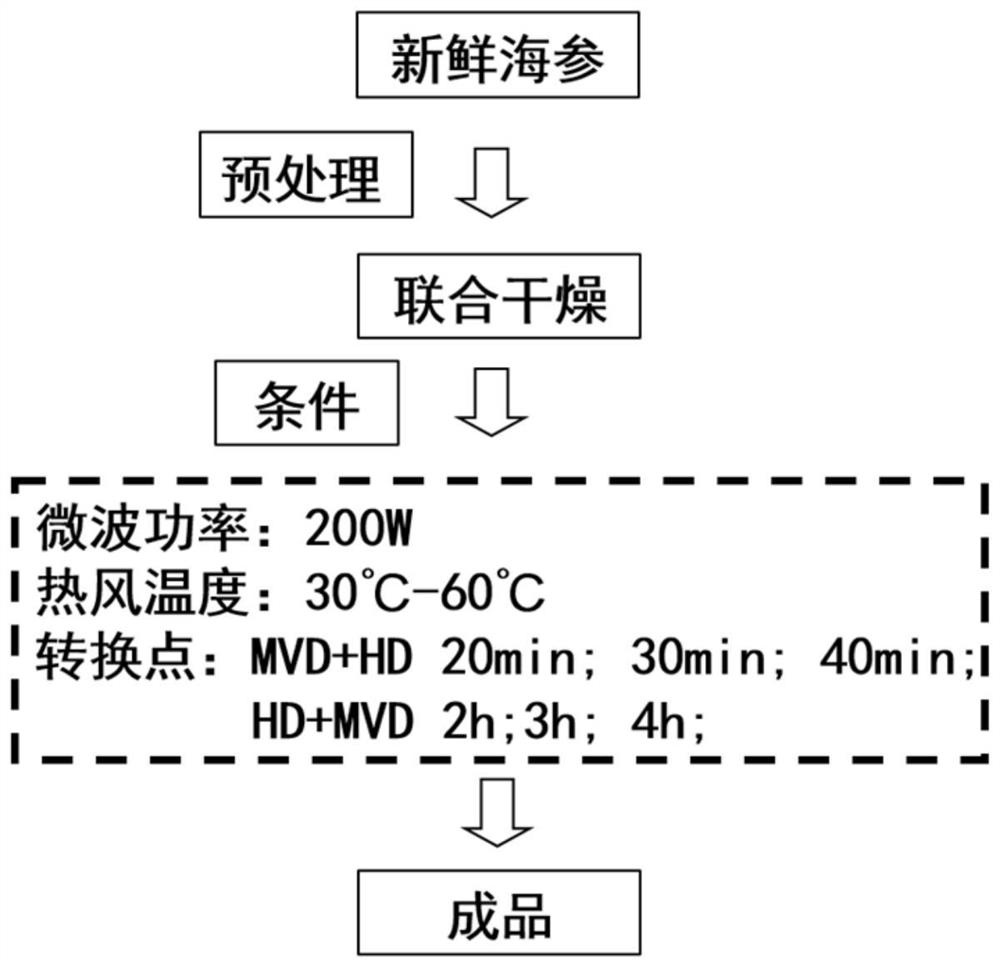

Method used

Image

Examples

Embodiment 1

[0028] S1. Selection of raw materials: select 25.0-33.5g of fresh sea cucumbers, plump, thick meat, fresh and pollution-free live sea cucumbers;

[0029] S2. Remove intestines and viscera: cut fresh sea cucumber from the ventral surface forward from the anus to 1 / 4 of the body length, quickly remove the intestines and viscera, wash with water, and drain;

[0030] S3. Boiling: put the sea cucumber in deionized water at 100°C and boil for 30 minutes to fix the shape of the sea cucumber;

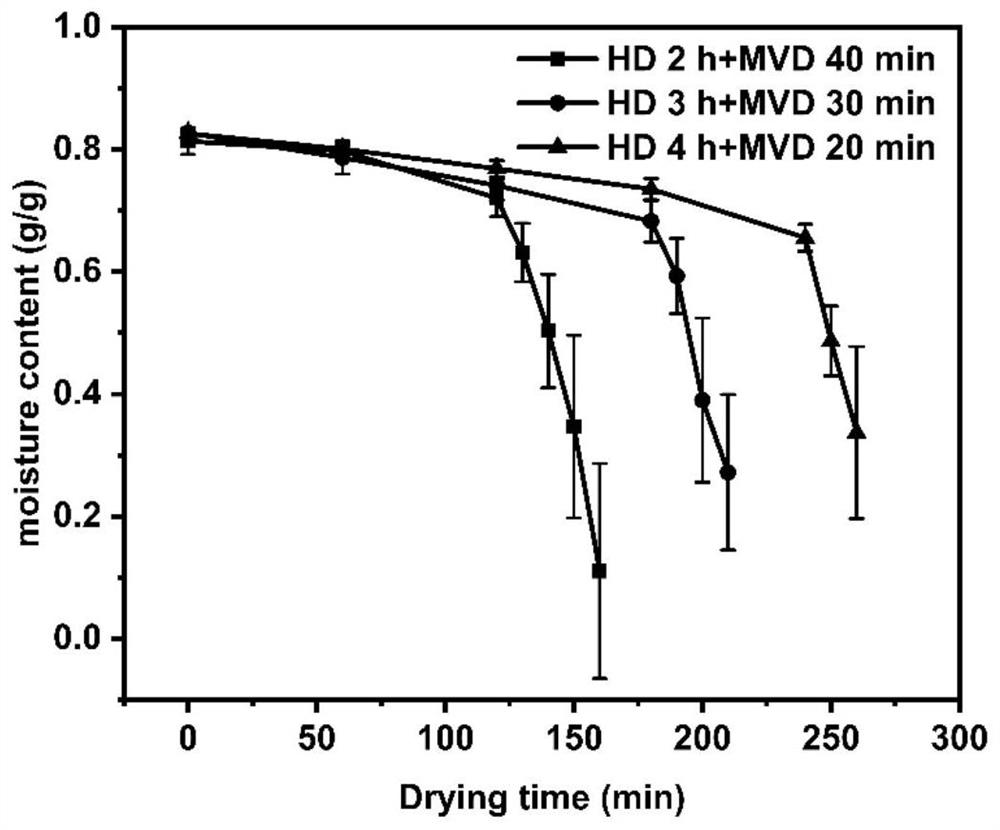

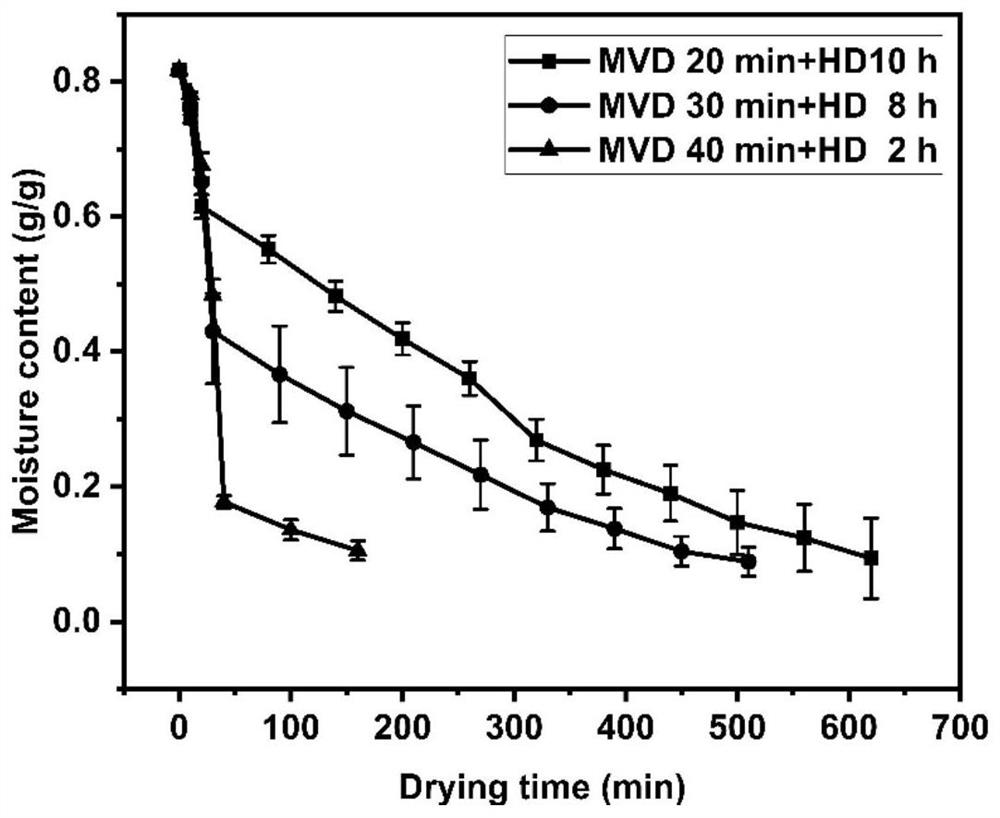

[0031] S4. Hot air drying: The hot air drying is carried out in the electric blast drying oven in the laboratory, the set temperature is 30°C, and the drained sea cucumbers are evenly placed on the tray of the drying oven. The specific drying method After drying for 1 hour, slow recovery for 1 hour, and repeat twice in total; measure the water content of sea cucumbers during slow recovery;

[0032] S5. Perform microwave vacuum drying on the sea cucumbers. Every 10 minutes of drying, slow dryin...

Embodiment 2

[0034] S1. Selection of raw materials: select 25.0-33.5g of fresh sea cucumbers, plump, thick meat, fresh and pollution-free live sea cucumbers;

[0035] S2. Remove intestines and viscera: cut fresh sea cucumber from the ventral surface forward from the anus to 1 / 4 of the body length, quickly remove the intestines and viscera, wash with water, and drain;

[0036] S3. Boiling: put the sea cucumber in deionized water at 100°C and boil for 30 minutes to fix the shape of the sea cucumber;

[0037] S4. Hot air drying: The hot air drying is carried out in the electric blast drying oven in the laboratory, the set temperature is 45°C, and the drained sea cucumbers are evenly placed on the tray of the drying oven. The specific drying method After drying for 1 hour, slow recovery for 1 hour, and repeat three times in total; measure the water content of sea cucumber during slow recovery;

[0038] S5. Perform microwave vacuum drying on the sea cucumbers. Every 10 minutes of drying, slow ...

Embodiment 3

[0040] S1. Selection of raw materials: select 25.0-33.5g of fresh sea cucumbers, plump, thick meat, fresh and pollution-free live sea cucumbers;

[0041] S2. Remove intestines and viscera: cut fresh sea cucumber from the ventral surface forward from the anus to 1 / 4 of the body length, quickly remove the intestines and viscera, wash with water, and drain;

[0042] S3. Boiling: put the sea cucumber in deionized water at 100°C and boil for 30 minutes to fix the shape of the sea cucumber;

[0043] S4. Hot air drying: The hot air drying is carried out in the electric blast drying oven in the laboratory, the set temperature is 60°C, and the drained sea cucumbers are evenly placed on the tray of the drying oven. The specific drying method As follows: follow the steps of drying for 1 hour and tempering for 1 hour, and repeat four times in total; measure the water content of sea cucumbers during the tempering;

[0044] S5. Carry out microwave vacuum drying to sea cucumbers, every 10 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com