Honeycomb paperboard with holes in honeycomb wall surface of sandwich layer

A technology of honeycomb cardboard and sandwich layer, which is applied in the direction of paper/cardboard layered products, papermaking, paper, etc., and can solve problems affecting the compressive strength of honeycomb cardboard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

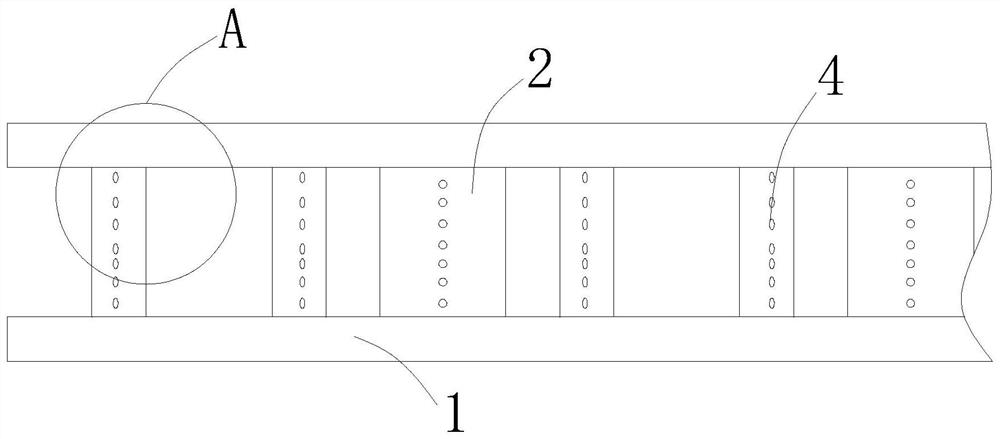

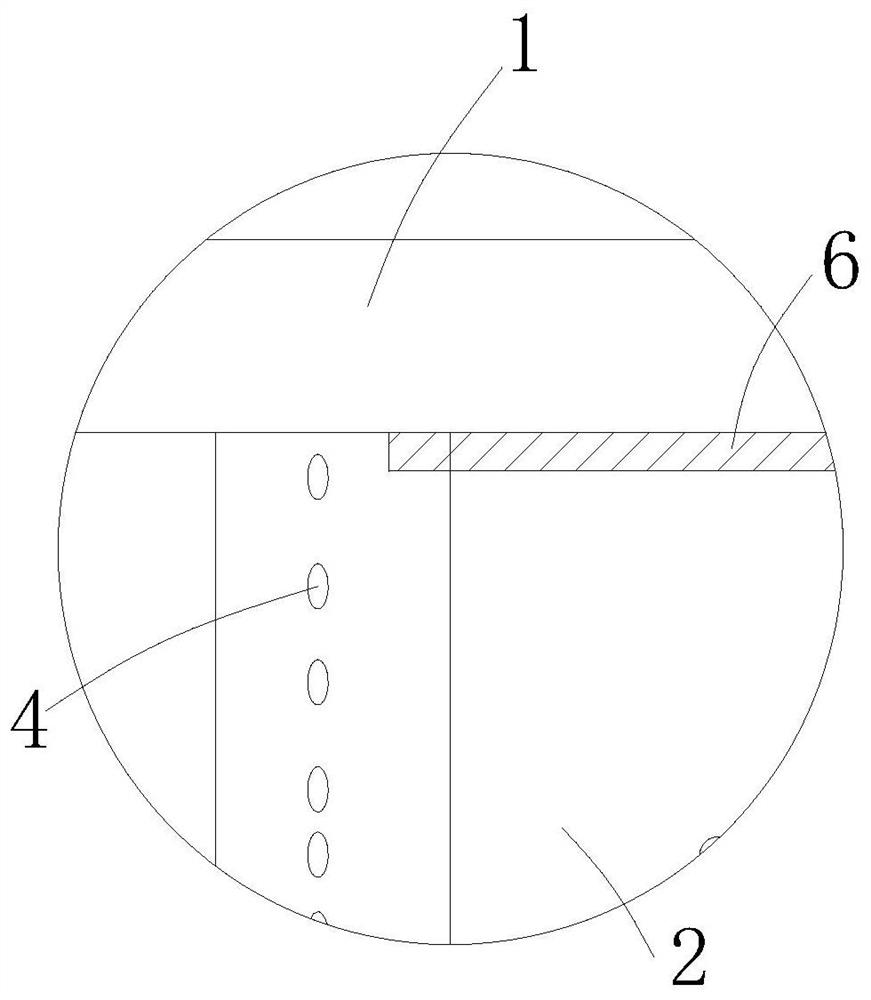

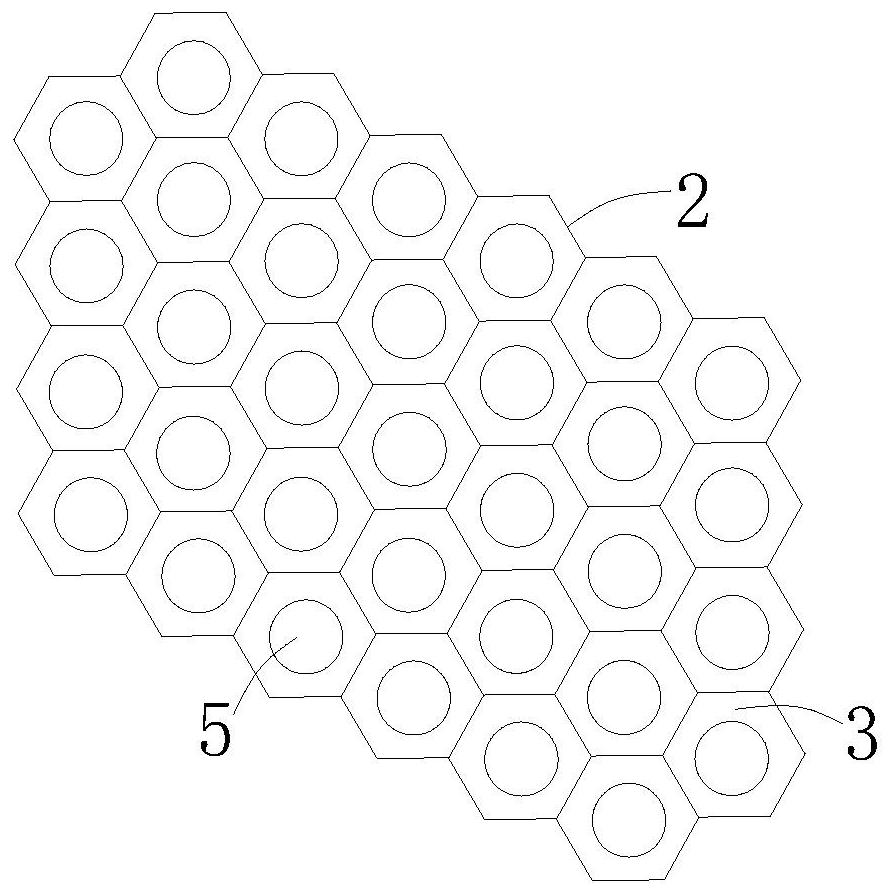

[0029] refer to Figure 1-3 As shown, the honeycomb paperboard with holes on the honeycomb wall surface of the sandwich layer includes honeycomb core paper 2, the face paper 1 arranged above and below the honeycomb core paper 2, honeycomb 3 is arranged in the honeycomb core paper 2, and the upper and lower side walls of the honeycomb 3 Adhesive layers 6 are arranged on both, and desiccant 5 is arranged between the two adhesive layers 6 , and a plurality of drying holes 4 are arranged on each spaced side wall of the honeycomb 3 , and the drying holes 4 are arranged in a vertical state.

[0030] In this embodiment, adhesive glue is applied on the facing sides of the two face papers 1 , the honeycomb core paper 3 is bonded to the two face papers 1 respectively, and the adhesive glue in the honeycomb 3 forms an adhesive layer 6 .

[0031] The desiccant includes in parts by weight: 20 parts of anhydrous calcium chloride, 10 parts of silicic acid, 5 parts of degreasing agent, and 3 ...

Embodiment 2

[0039] refer to Figure 1-3 As shown, the honeycomb paperboard with holes on the honeycomb wall surface of the sandwich layer includes honeycomb core paper 2, the face paper 1 arranged above and below the honeycomb core paper 2, honeycomb 3 is arranged in the honeycomb core paper 2, and the upper and lower side walls of the honeycomb 3 Adhesive layers 6 are arranged on both, and desiccant 5 is arranged between the two adhesive layers 6 , and a plurality of drying holes 4 are arranged on each spaced side wall of the honeycomb 3 , and the drying holes 4 are arranged in a vertical state.

[0040] In this embodiment, adhesive glue is applied on the facing sides of the two face papers 1 , the honeycomb core paper 3 is bonded to the two face papers 1 respectively, and the adhesive glue in the honeycomb 3 forms an adhesive layer 6 .

[0041]The desiccant includes in parts by weight: 22 parts of anhydrous calcium chloride, 12 parts of silicic acid, 7 parts of degreasing agent, and 4 p...

Embodiment 3

[0049] refer to Figure 1-3 As shown, the honeycomb paperboard with holes on the honeycomb wall surface of the sandwich layer includes honeycomb core paper 2, the face paper 1 arranged above and below the honeycomb core paper 2, honeycomb 3 is arranged in the honeycomb core paper 2, and the upper and lower side walls of the honeycomb 3 Adhesive layers 6 are arranged on both, and desiccant 5 is arranged between the two adhesive layers 6 , and a plurality of drying holes 4 are arranged on each spaced side wall of the honeycomb 3 , and the drying holes 4 are arranged in a vertical state.

[0050] In this embodiment, adhesive glue is applied on the facing sides of the two face papers 1 , the honeycomb core paper 3 is bonded to the two face papers 1 respectively, and the adhesive glue in the honeycomb 3 forms an adhesive layer 6 .

[0051] The desiccant includes in parts by weight: 25 parts of anhydrous calcium chloride, 13 parts of silicic acid, 8 parts of degreasing agent, and 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com