Plant extract interior wall latex paint and preparation method thereof

A technology for interior wall latex paint and extraction, which is applied to the field of interior wall latex paint to achieve the effects of high stability, low cost of raw materials and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

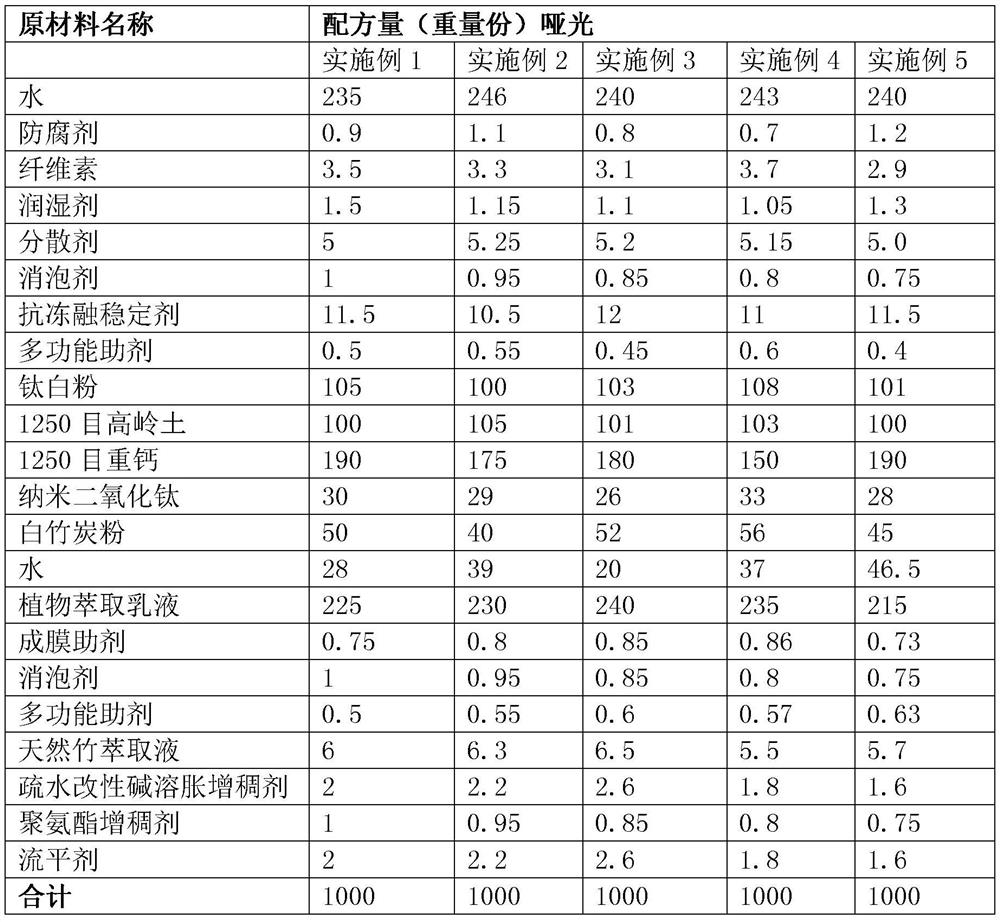

[0056] The formula of a plant extract interior wall latex paint is shown in Table 2.

[0057] The formula of table 2 experimental example 1

[0058]

[0059] The preparation method of this experimental example is as follows:

[0060] ① First add water to the production tank, turn on the high-speed disperser equipment, and adjust the dispersion speed to 350r / min. Add raw materials No. 2-8 in sequence, adjust the dispersion speed to 400r / min, and disperse and stir for 5 minutes to enter the next process stage;

[0061] ② Adjust the dispersion speed to 800r / min-1200r / min (adjusted according to the production volume), add raw materials No. 9-13 in turn, disperse and stir for 30 minutes, and test the fineness. After the fineness is ≤ 35μm, enter the next process stage ;

[0062] ③ Adjust the dispersion speed to 500r / min, add raw materials No. 14-16 in sequence, and disperse for 5 minutes to enter the next process stage;

[0063] ④ Adjust the dispersion speed to 400r / min, add...

experiment example 2

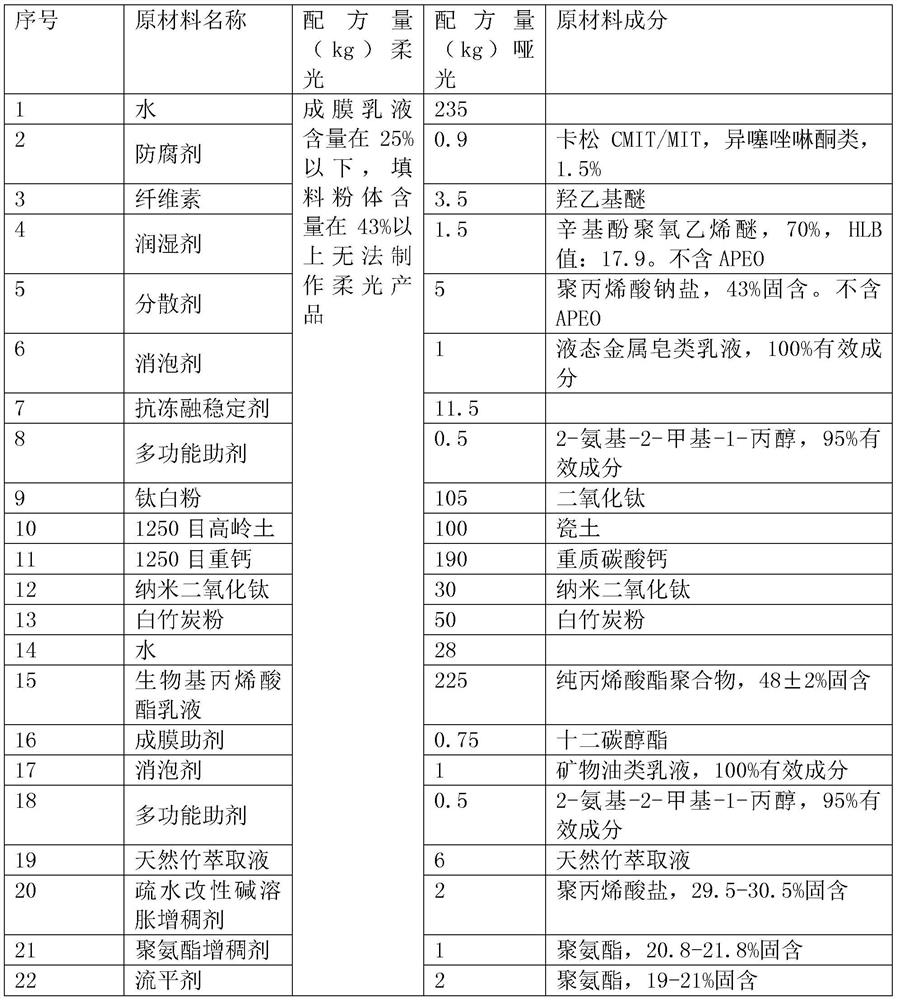

[0070] The formula of a plant extract interior wall latex paint is shown in Table 4.

[0071]

[0072]

[0073] The formula of table 4 experimental example 2

[0074] The preparation method of the above coating is the same as in Experimental Example 1.

[0075] The detection results of this experimental example are shown in Table 5.

[0076] The detection result of table 5 experimental example 2

[0077] Fineness 35μm Biobased content 4.6% viscosity 25℃105KU Effective rate of killing bacteria in 2 hours 99.12% pH 9 BaiDu 0.905 contrast ratio 0.95 contain 56.25% (matte) color White Scrub resistant 10000 times (matte)

experiment example 3

[0079] The formula of a plant extract interior wall latex paint is shown in Table 6.

[0080] The formula of table 6 experimental example 3

[0081]

[0082]

[0083] The preparation method of the above coating is the same as in Experimental Example 1.

[0084] The detection results of this experimental example are shown in Table 7.

[0085] The detection result of table 7 experimental example 3

[0086] Fineness 35μm Biobased content 4.8% viscosity 25℃105KU Effective rate of killing bacteria in 2 hours 99.4% pH 9 BaiDu 0.905 contrast ratio 0.955 contain 57.95% (matte) color White Scrub resistant 10000 times (matte)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com