Assembly type bathroom system and assembly method thereof

An assembly method and assembly technology, applied in the field of building bathroom, can solve the problems of cumbersome cleaning, low assembly efficiency, and high requirements for installation site space environment, and achieve the effect of large space utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

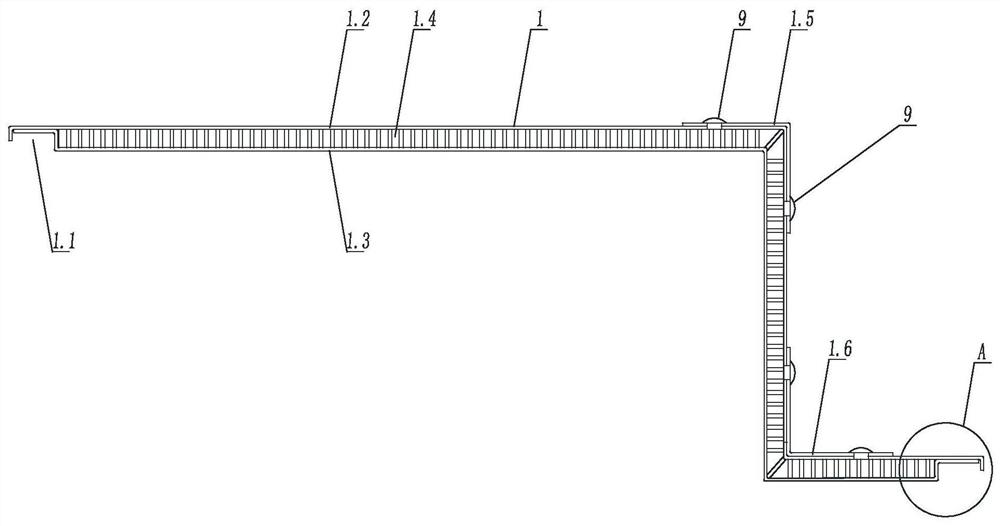

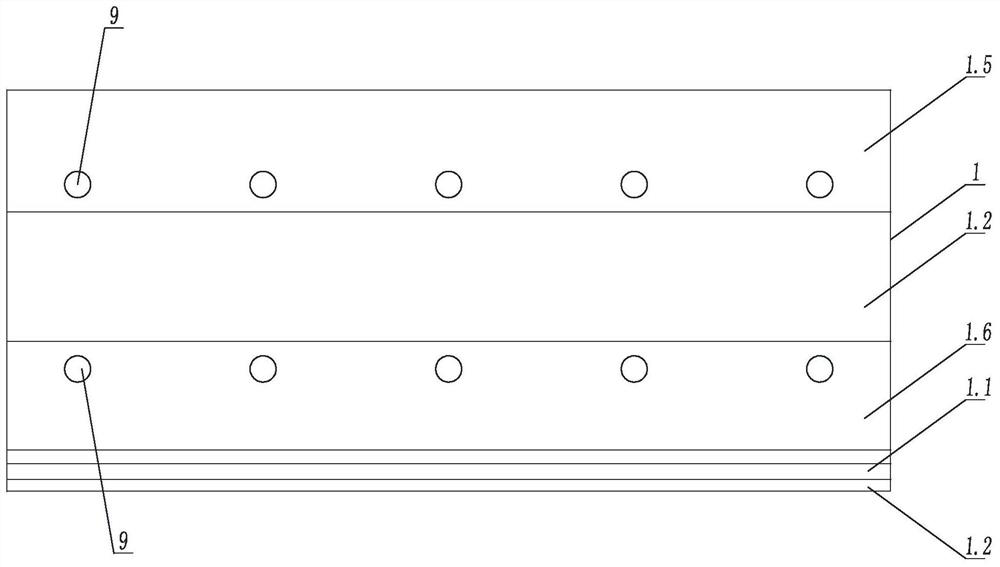

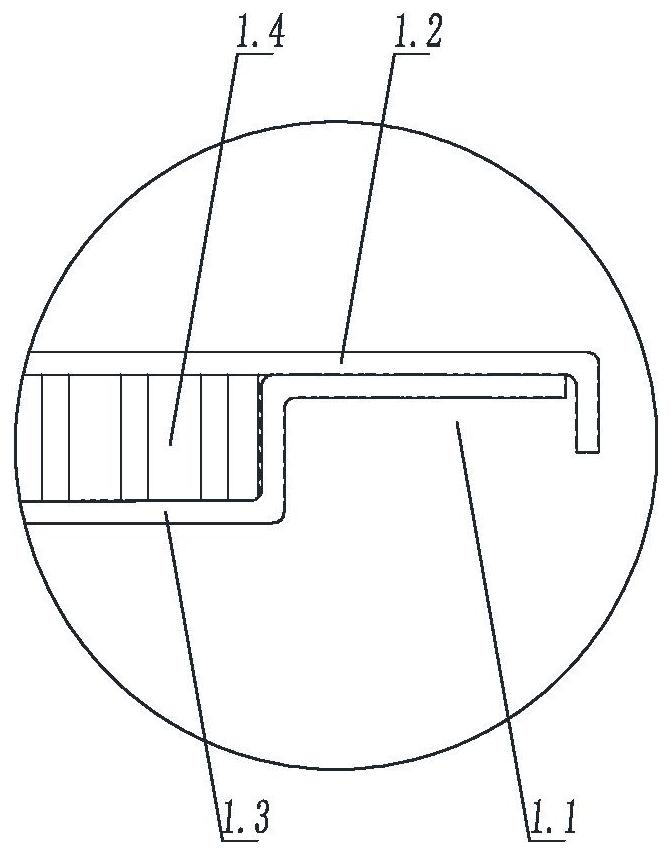

[0045] figure 1 Schematic diagram of the structure of the ceiling; figure 2 for figure 1 right view of image 3 for figure 1 Enlarged view of part A. Such as Figures 1 to 3 As shown, a prefabricated bathroom system includes a wall panel and a ceiling 1. The ceiling 1 is a Z-shaped panel. The Z-shaped panel is bent from one panel. The corners of the Z-shaped panel are at right angles. Set the angle aluminum reinforcement, the length of the angle aluminum is consistent with the length of the Z-shaped plate, the angle aluminum is fixedly connected with the two right-angle sides of the Z-shaped plate, and the notch 1.1 is set on the edge of the right-angle side of the Z-shaped plate, and the notch 1.1 The length is consistent with the length of the Z-shaped plate, the notch 1.1 is integrally formed with the Z-shaped plate, the opening direction of the notch 1.1 is the direction of the decorative surface, and the angle aluminum is arranged on the Z-shaped plate opposite to t...

Embodiment 2

[0064] Figure 11 It is a schematic diagram of the connection between the wallboards of the second embodiment of the present invention (top view direction); Figure 12 It is the bottom view of embodiment two ceiling; Figure 13 It is the left view of the second embodiment. Such as Figures 11 to 13 As shown, embodiment two is an assembly method when a corner needs to be installed, including the following steps:

[0065] Step 1, according to the size of the installation site, pre-set the size of the matching wallboard and the size of the ceiling, and install the pendant 2 and the fastener 3 on the corresponding wallboard; the wallboard in the second embodiment is aluminum The honeycomb panel comprises a first wall panel 4, a second wall panel 5, a third wall panel 6, a fourth wall panel 7, and a fifth wall panel 8. A pendant 2c is set on one side of the first wall panel 4, and The other side of the wallboard 4 is provided with a mirrored hanging part 2c', and the fasteners ...

Embodiment 3

[0075] Figure 15 It is a schematic diagram of the connection between the three wallboards of the embodiment of the present invention (top view direction); Figure 16 It is the bottom view of embodiment three ceilings; Figure 17 It is the left view of the third embodiment. Such as Figures 15 to 17 As shown, the third embodiment is due to the limitation of the installation site, such as the height of the elevator or the height of the door, etc., it is necessary to disassemble the wall panel and the ceiling into small pieces for installation. The assembly method of the third embodiment includes the following steps:

[0076] Step 1, pre-set the size of the matching wallboard and the size of the ceiling according to the size of the installation site, and install the pendant 2 and the fastener 3 on the corresponding wallboard; the wallboard in the third embodiment is aluminum Honeycomb panels, including the first wall panel 4, the second wall panel 5, the third wall panel 6, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com