Smelting equipment for cable processing based on graphene

A smelting equipment and graphene technology are applied in the field of graphene-based smelting equipment for cable processing, and can solve problems such as affecting the electrical conductivity of graphene cables, poor control accuracy of filling amount, and graphene content lower than a specified value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

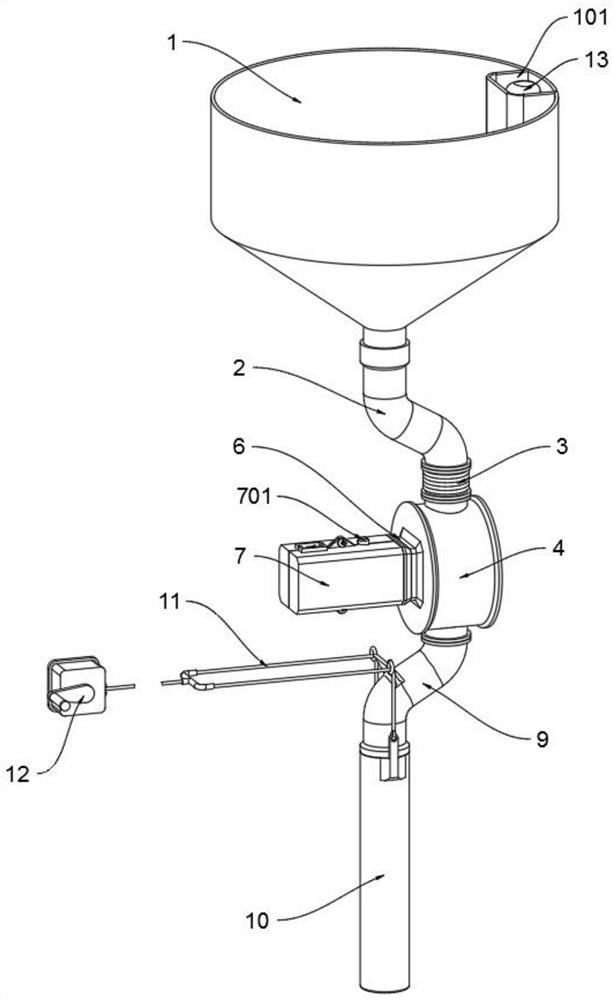

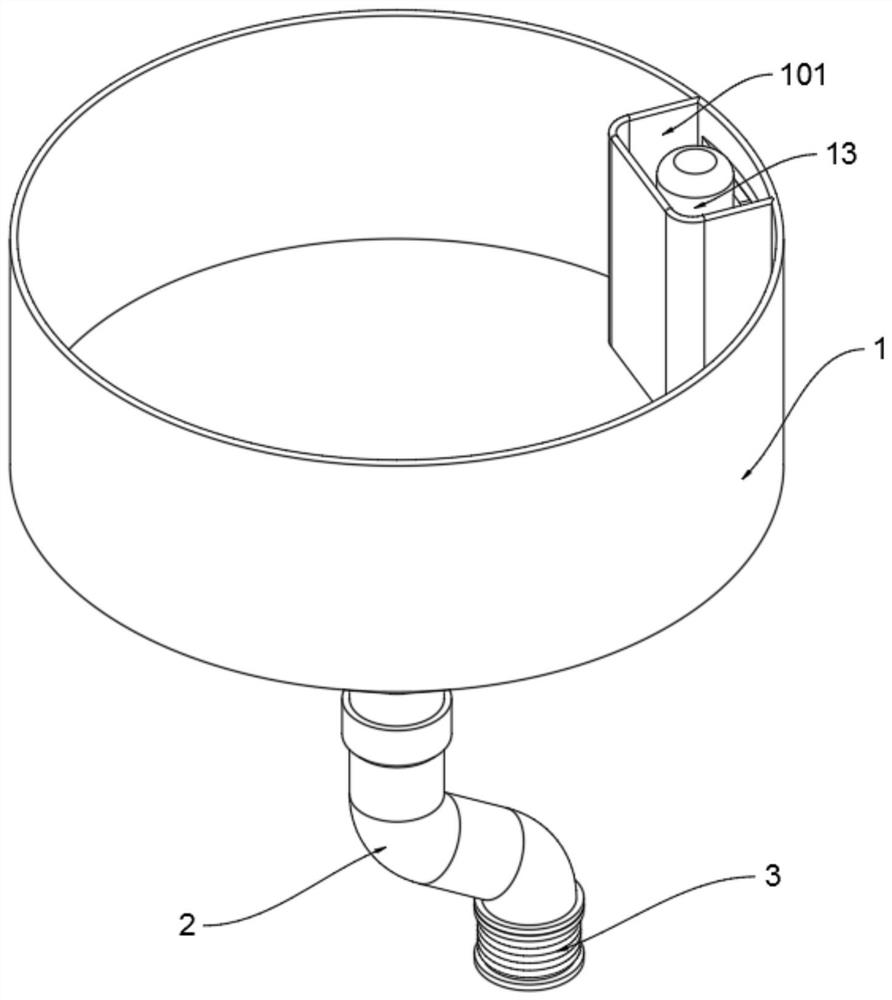

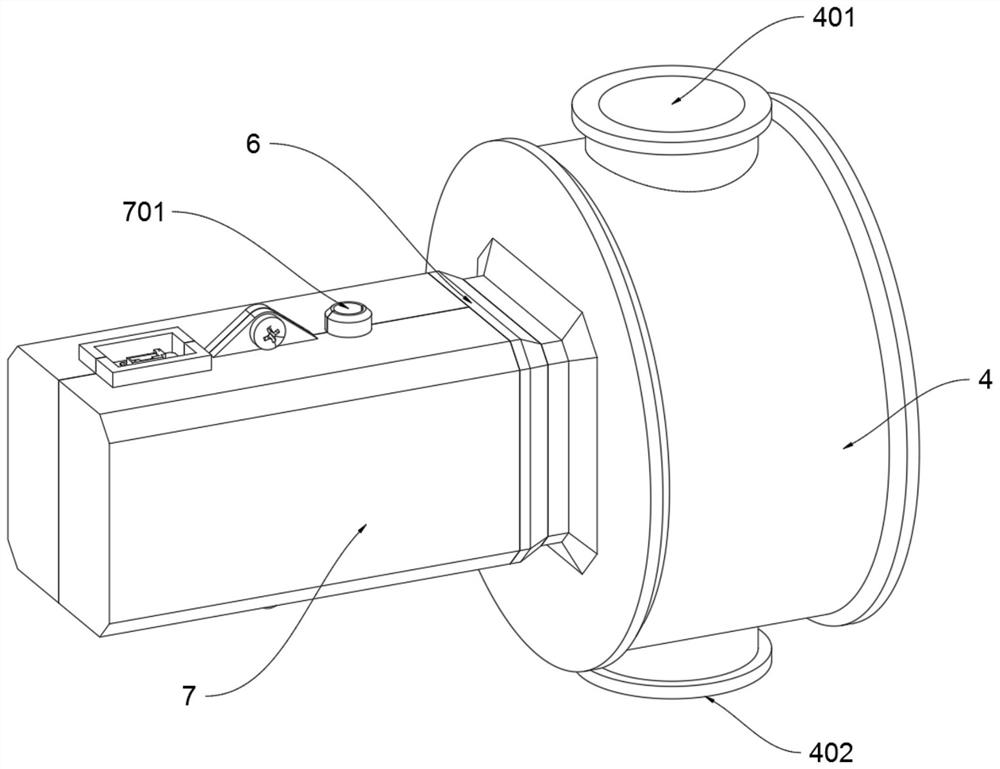

[0030] as attached figure 1 to attach Figure 7 Shown:

[0031] The present invention provides a graphene-based smelting equipment for cable processing, comprising a storage funnel 1, a quantitative filling box 4, a heat insulation shell 7, a discharge pipe 9 and a hand crank 12; the storage funnel 1 passes through the feed pipe 2 is connected with the telescopic tube 3, and the vibrating motor 13 is located in the storage funnel 1; the inside of the quantitative filling box 4 is a hollow structure, and the top of the quantitative filling box 4 is connected with the feeding pipe 2 through the telescopic tube 3, and Turning block 5 is located inside quantitative filling box 4; heat insulation shell 7 is installed on the outside of quantitative filling box 4 through heat insulation connection seat 6; heat insulation shell 7 is made of two parts, and heat insulation shell 7 two parts are connected on the Together, and the upper and lower sides of the heat-insulating shell 7 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com