Milling chatter prediction method for thin bottom plate

A technology of milling chatter and prediction method, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problem of reduced accuracy in the stability domain, no consideration of the influence of dynamic cutting forces, and unfavorable machining process stability parameters selection and other problems, to achieve the effect of improving the accuracy of stability prediction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

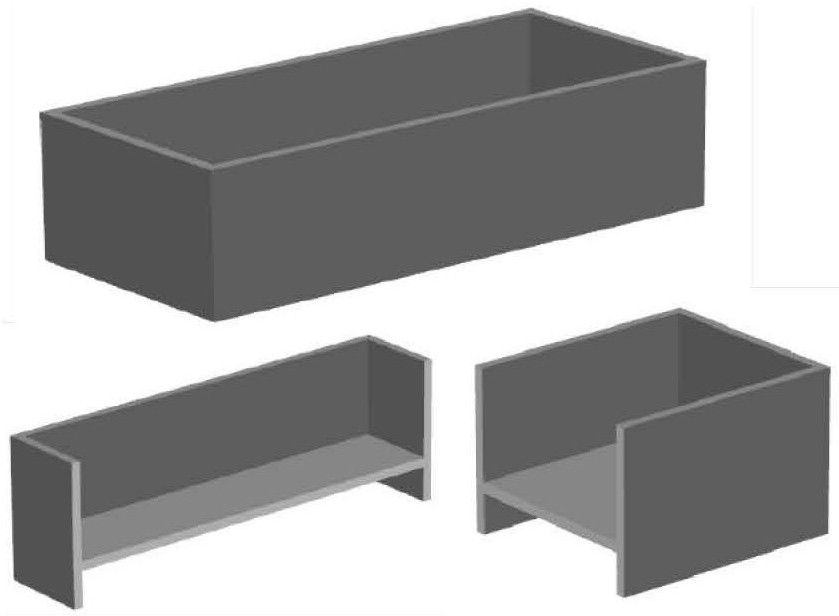

[0045] Example 1: The size of the cutting part of the cavity is 172mm×70mm×3mm, the material is aluminum alloy 7075, the modulus of elasticity is 71.0GPa, and the density is 2830kg / m 3 , Poisson's ratio is 0.3.

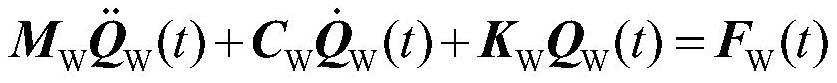

[0046] 1. The dynamic state equation of the workpiece during milling is:

[0047]

[0048] m W ,C W ,KW Represents the mass, damping, and stiffness matrices of the initial workpiece; and Q W (t) represents the acceleration, velocity and displacement vector of the workpiece under physical coordinates; F W (t) represents the dynamic cutting force acting on the workpiece.

[0049] 2. During the milling process of thin base plate, the dynamic cutting force acting on the workpiece at time t:

[0050]

[0051] K tra Represents the cutting force coefficient matrix, K tra =[875,350,296] T ; g(φ j (t,a p )) represents the cutting state function, its value is 1 when the tooth participates in cutting, and the value is 0 when it does not participate in cutting; ...

Embodiment 2

[0073] Example 2: The size of the processed part of the cavity is 180mm×65mm×3.5mm; the material is aluminum alloy 7050, the modulus of elasticity is 71.7GPa, and the density is 2830kg / m 3 , Poisson's ratio is 0.3.

[0074] 1. The dynamic state equation of the workpiece during milling is:

[0075]

[0076] m W ,C W ,K W Represents the mass, damping, and stiffness matrices of the initial workpiece; and Q W (t) represents the acceleration, velocity and displacement vector of the workpiece under physical coordinates; F W (t) represents the dynamic cutting force acting on the workpiece.

[0077] 2. During the milling process of thin base plate, the dynamic cutting force acting on the workpiece at time t:

[0078]

[0079] K tra Represents the cutting force coefficient matrix, K tra =[896,371,311] T ; g(φ j (t,a p )) represents the cutting state function, its value is 1 when the tooth participates in cutting, and the value is 0 when it does not participate in cut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com