Test device with electromagnetic shielding and capable of releasing melt

A technology of electromagnetic shielding and testing equipment, which is applied in the field of testing equipment for molten materials and testing equipment for releasing molten materials with electromagnetic shielding. Simulation test vitrification treatment and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

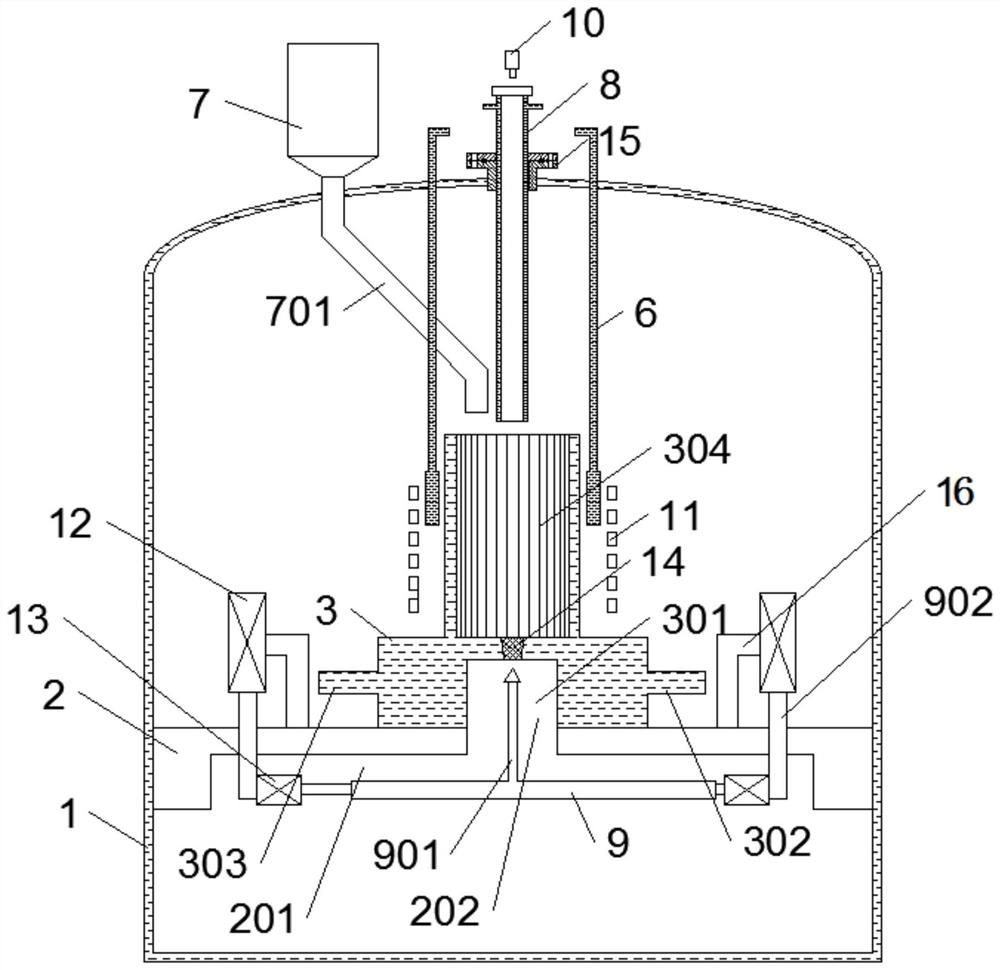

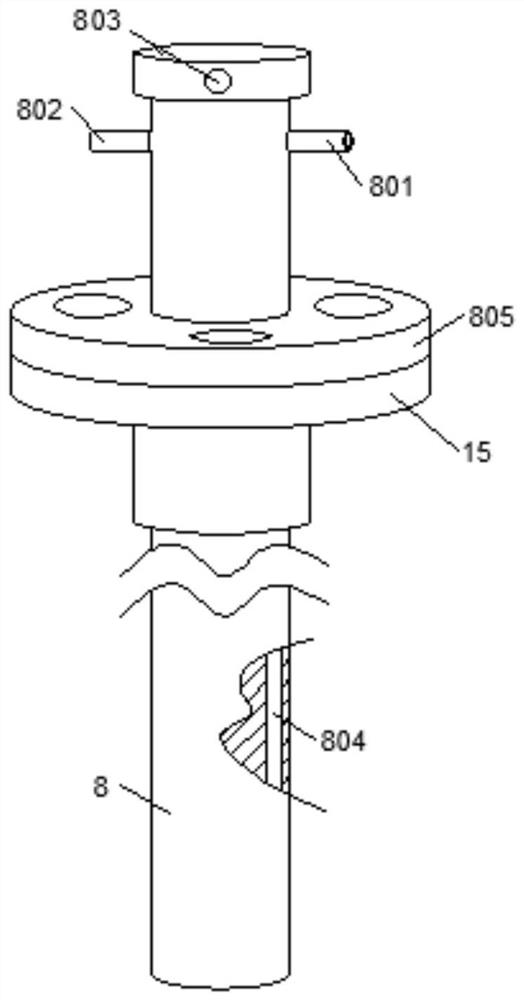

[0058] like Figure 1-Figure 6 As shown, a test device with electromagnetic shielding and releasable melt provided in this embodiment includes a furnace body of the device, a base support is fixed inside the furnace body of the device, and the upper side of the base support is provided with A cold crucible, the cold crucible is provided with a crucible body, an induction coil is sleeved on the crucible body, and an electromagnetic shielding device that can move along the axis of the crucible is arranged between the induction coil and the crucible body; the crucible body is Water-cooled tubes and refractory filling materials.

[0059] Through the above technical solution, the crucible body is composed of water-cooled tubes and refractory filling materials, instead of dividing the crucible chassis and crucible body, so the structure is simple, the effect of melting is obvious, and the efficiency of detection and the convenience of use are improved.

Embodiment 2

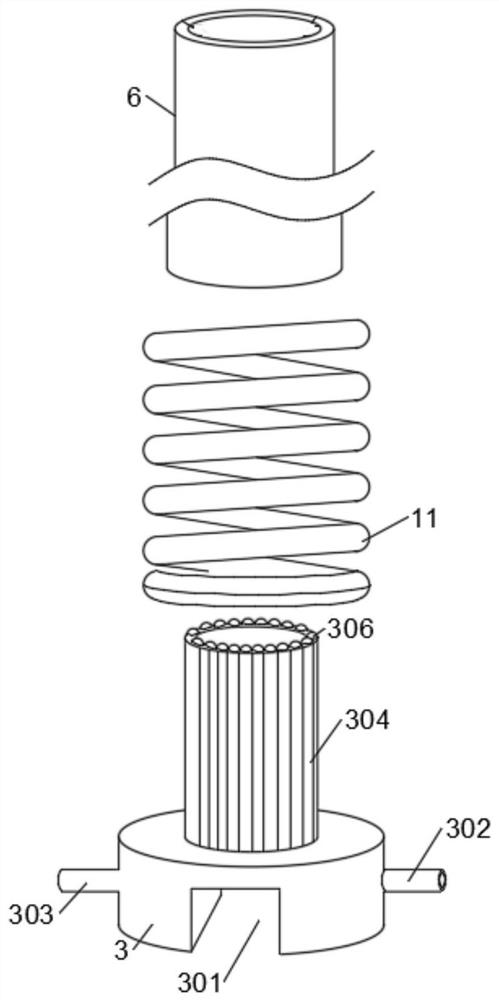

[0061] The induction coil is sleeved on the periphery of the crucible body, the induction coil is connected to the external cooling circulation system through a water pipe, and there is a gap between the induction coil and the crucible body, the gap is to ensure that the electromagnetic shielding device can Move up and down along the axis of the crucible.

[0062] The induction coil is made of copper tube, with cooling water inside, coiled on the outside of the crucible body, and converts the high-frequency alternating current generated by the power supply into a high-frequency alternating electromagnetic field, and then heats and melts the test working medium in the cold crucible, simulating the interior of the melt pool heat source.

[0063] Further, the crucible body is cylindrical, and the outer circumference of the crucible body is arranged with several first water-cooled tubes and second water-cooled tubes, each of the first water-cooled tubes and each of the second wate...

Embodiment 3

[0067] The bottom of the cold crucible is provided with a cold crucible release groove, the center of the bottom of the cold crucible is provided with a discharge hole, the inside of the discharge hole is provided with a plug, and the bottom of the discharge hole is provided with a release mechanism , the release mechanism is fixedly provided with a thimble rod on the same vertical axis as the plug;

[0068] The release mechanism includes a longitudinal push rod, a longitudinal telescopic machine, a horizontal push rod, a horizontal telescopic machine and a thimble bar, and two of the longitudinal telescopic machine, the horizontal telescopic machine and the longitudinal push rod are provided, and the longitudinal push One end of the rod is connected to the longitudinal telescopic machine, the other end of the longitudinal push rod is connected to the horizontal push rod, and the horizontal telescopic machine is also arranged on the longitudinal push rod, and the horizontal tel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com