Line production device for wrapping zongzi

A technology of assembly line operation and zongzi, which is applied in packaging, cleaning methods and utensils, and cleaning methods using liquids, etc. It can solve the problems of affecting the quality of zongzi products, reducing work efficiency, and increasing error rates, so as to reduce the workload and errors of workers. The effect of improving efficiency, improving production efficiency and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

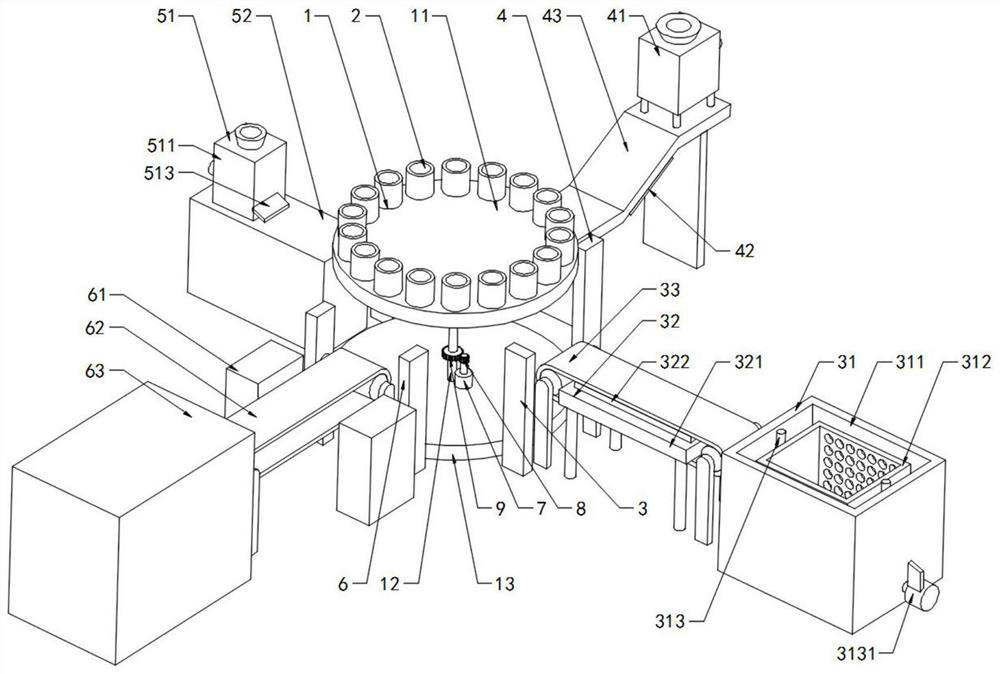

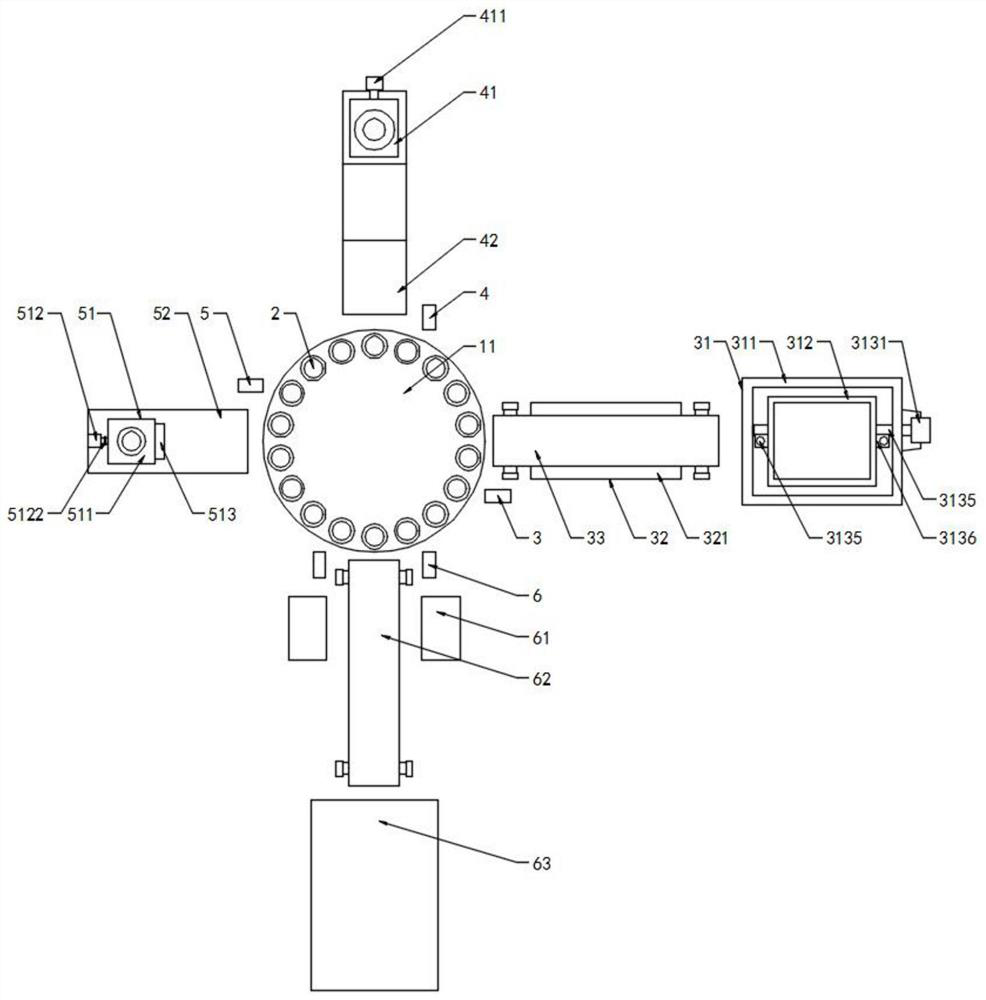

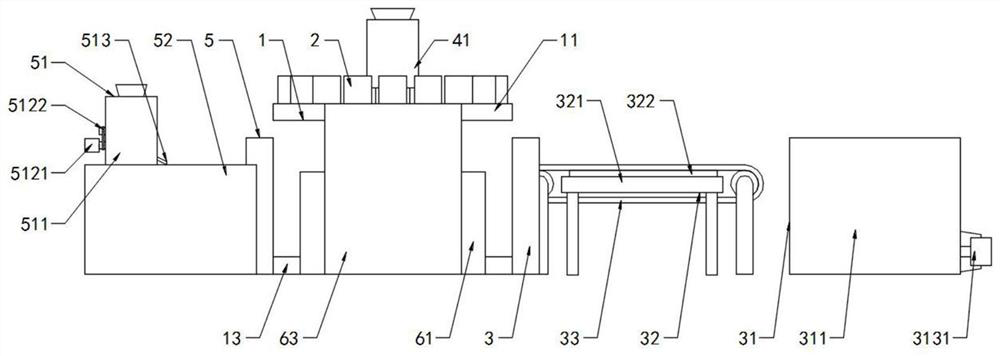

[0037] see Figure 1-8, a kind of assembly line device for wrapping zongzi, comprising a workbench 1, the workbench 1 is composed of a top plate 11 and a bottom plate 13 rotated through a rotating column 12, and the top of the top plate 11 is fixedly connected with a plurality of zongzi leaf holders 2 near the outside to keep the work The zong leaves in the process will not scatter, and a plurality of zong leaf holders 2 are equiangularly distributed around their center lines. The first drive motor 7 is installed on the bottom plate 13, and an active cylinder is sleeved outside the output shaft of the first drive motor 7. The gear 8 and the outer side of the rotating column 12 are sleeved with the driven cylindrical gear 9 meshing with the driving cylindrical gear 8 to realize the uniform rotation of the top plate 11. There are multiple stations on the outside of the workbench 1 equiangularly distributed around its axis. Leaf preparation station 3, glutinous rice preparation s...

Embodiment 2

[0039] The difference from Example 1 is that

[0040] see Figure 5 and Figure 6 The reed leaf cleaning device 31 is made up of a water tank 311, a cleaning tank 312, a lifting mechanism 313 and an ultrasonic cleaning mechanism 314. The ultrasonic cleaning mechanism 314 is located at the bottom of the water tank 311. Under the action of ultrasonic waves, the surface of the reed leaves is fully cleaned. Lifting mechanism 313 is fixedly connected, realizes the purpose that cleaning tank 312 enters and exits water tank 311, is convenient to pick and place of reed leaves.

[0041] see Figure 5 and Figure 6 , the cleaning box 312 is a porous box, and the ultrasonic wave is transmitted to the surface of the reed leaf through the water medium to clean the dirt on the surface of the reed leaf. Gear 3134, transmission screw rod 3135 and slide block 3136 are formed, and transmission shaft 3132 is installed between the inner surface wall on both sides of water tank 311 close to th...

Embodiment 3

[0044] The difference from Example 1 is that

[0045] see figure 1 , Figure 4 and Figure 7 , the vertical section of glutinous rice placing platform 43 is " Z " font, and glutinous rice washing device 41 is installed on the horizontal end of its top, and glutinous rice washing device 41 is made up of the 3rd drive motor 411 and stirring rod 412, and the 3rd drive motor 411 The output shaft of the output shaft is connected with the stirring rod 412 to drive and clean the glutinous rice. The glutinous rice drying device 42 is composed of a mounting plate 421 and a second heating plate 422. The mounting plate 421 is fixedly connected to the bottom of the inclined surface of the glutinous rice placing platform 43, and the second The heating plate 422 is in contact with the bottom of the inclined surface, and the cleaned glutinous rice after elutriation is dried by the second heating plate 422, and slides down to the horizontal end of the glutinous rice placing platform 43 bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com