Leaching equipment for high-concentration heavy metal contaminated soil and leaching method thereof

A technology for polluted soil and heavy metals, which is applied in the restoration of polluted soil and the improvement of process efficiency, can solve the problems of difficult use, limited leaching mechanism and reaction conditions, and difficult to meet the requirements of treatment effect, and achieves simple components. , Good rinsing and removal effect, the effect of the method is not complicated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

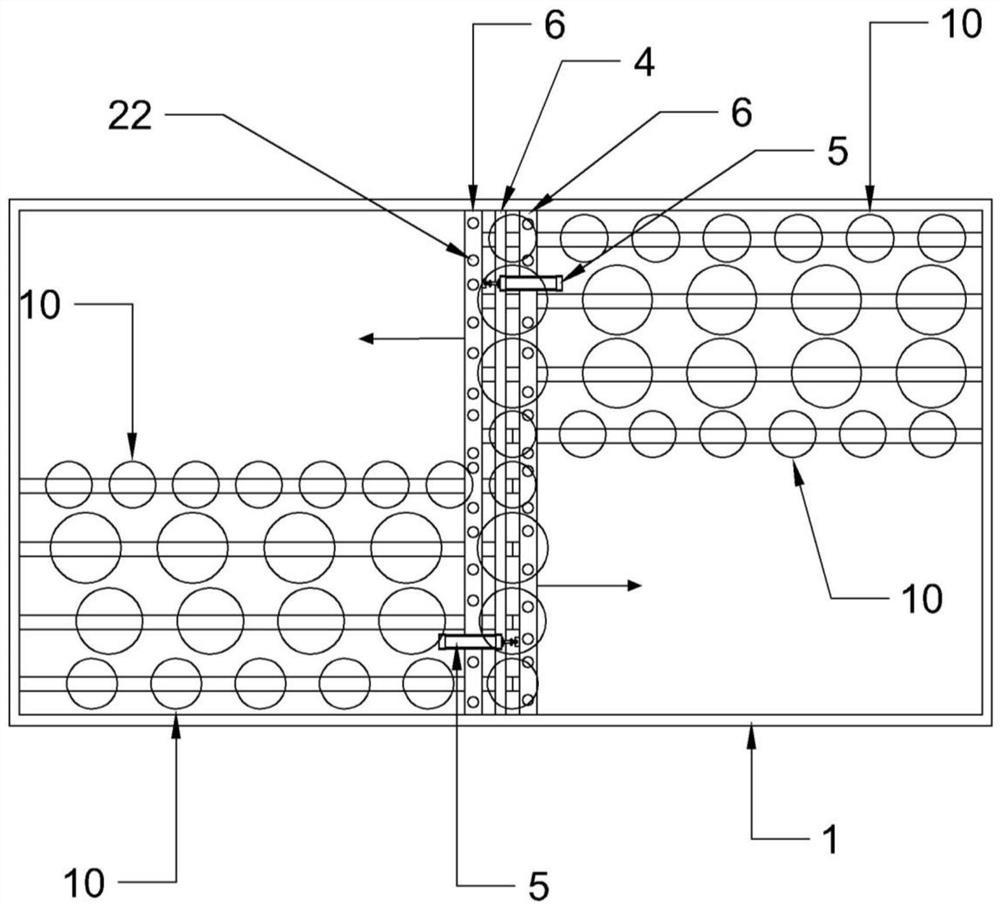

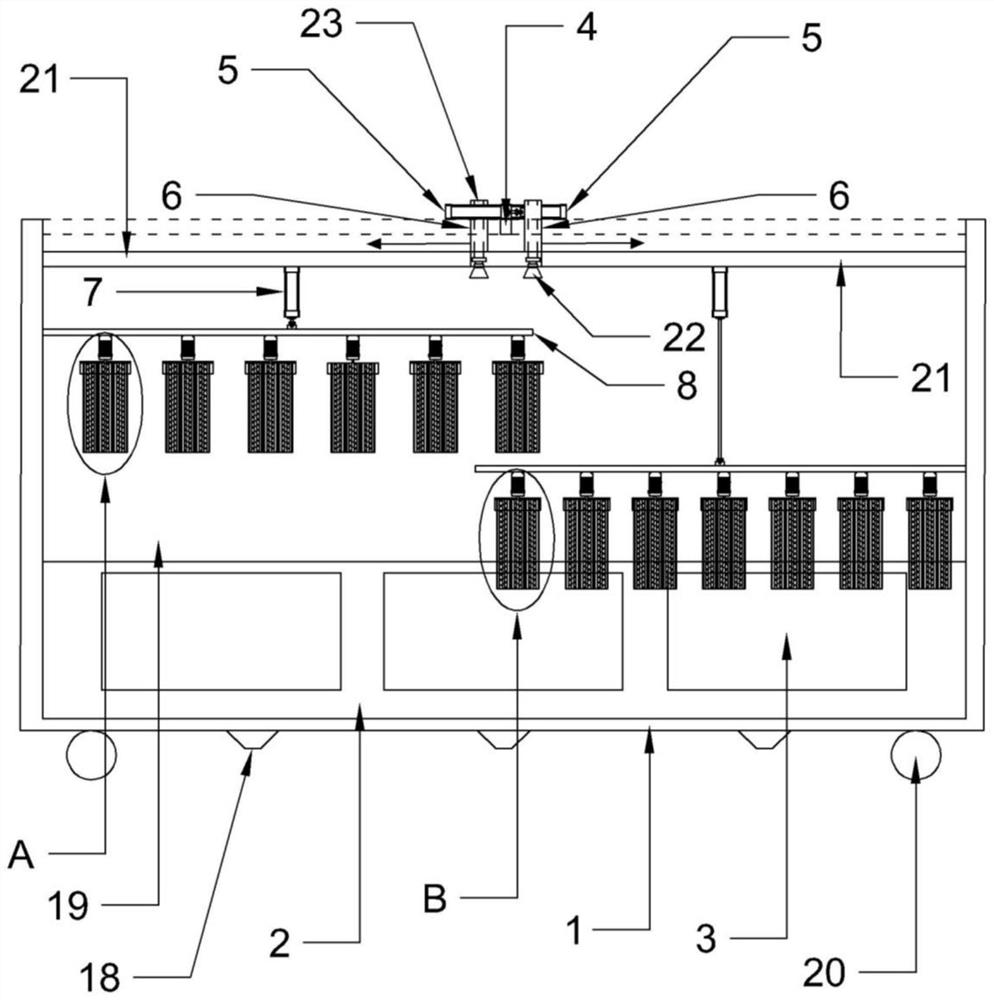

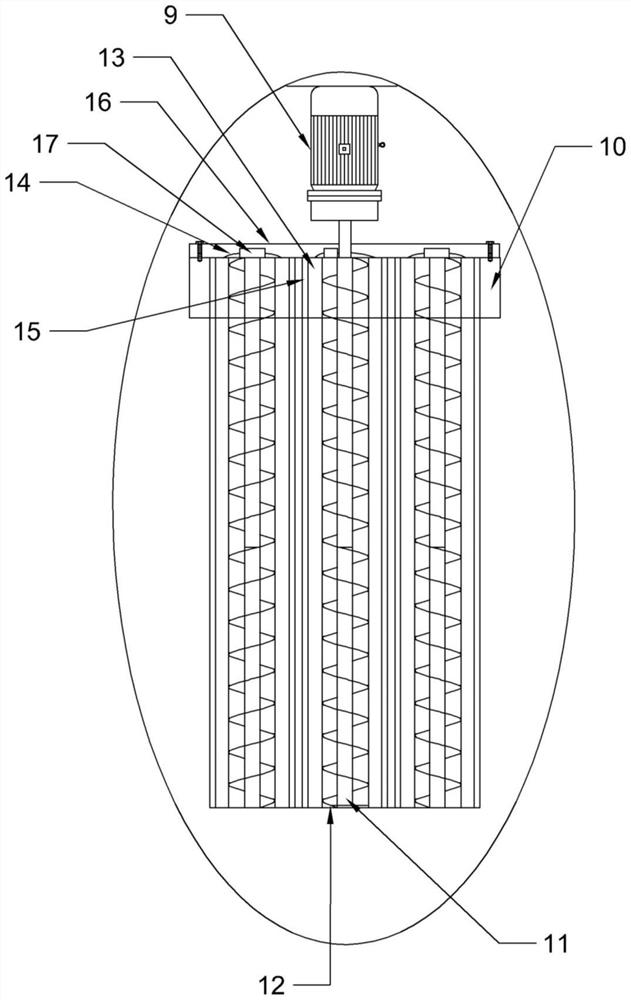

[0042] refer to Figure 1-6 , a kind of rinsing equipment and rinsing method of high-concentration heavy metal polluted soil, comprising the following steps:

[0043] (1) Soil sample collection: Collect heavily chromium-contaminated soil samples with a hexavalent chromium content of 6000mg / kg and air-dry them indoors, and select soil samples with a particle size of 0.25-3.00mm;

[0044] (2) Compound leaching of soil samples: Weigh 100g of soil samples, add deionized water according to the water-to-soil ratio of 10:1, and place the soil samples in the leaching equipment for high-concentration heavy metal-contaminated soil at a room temperature of 28-33°C , using eluent water for the first leaching, shaking for 60 minutes, filtering to obtain the supernatant and measuring the concentration of hexavalent chromium in the soil;

[0045] Collect and filter the soil, then add 0.5mol / L eluent sodium carbonate, place the soil sample in the leaching equipment for high-concentration hea...

Embodiment 2

[0056] refer to Figure 1-6 , a kind of rinsing equipment and rinsing method of high-concentration heavy metal polluted soil, comprising the following steps:

[0057] (1) Soil sample collection: Collect heavily chromium-contaminated soil samples with a hexavalent chromium content of 6000mg / kg and air-dry them indoors, and select soil samples with a particle size of 0.25-3.00mm;

[0058] (2) Compound leaching of soil samples: Weigh 100g of soil samples, add deionized water according to the water-to-soil ratio of 10:1, and place the soil samples in the leaching equipment for high-concentration heavy metal-contaminated soil at a room temperature of 28-33°C , using eluent water for the first leaching, shaking for 60 minutes, filtering to obtain the supernatant and measuring the concentration of hexavalent chromium in the soil;

[0059] Collect and filter the soil, place the soil sample in the leaching equipment for high-concentration heavy metal-contaminated soil at a room temper...

Embodiment 3

[0070] refer to Figure 1-6 , a kind of rinsing equipment and rinsing method of high-concentration heavy metal polluted soil, comprising the following steps:

[0071] (1) Soil sample collection: Collect heavily chromium-contaminated soil samples with a hexavalent chromium content of 6000mg / kg and air-dry them indoors, and select soil samples with a particle size of 0.25-3.00mm;

[0072] (2) Compound leaching of soil samples: Weigh 100g of soil samples, add deionized water according to the water-to-soil ratio of 10:1, and place the soil samples in the leaching equipment for high-concentration heavy metal-contaminated soil at a room temperature of 28-33°C , using eluent water for the first leaching, shaking for 60 minutes, filtering to obtain the supernatant and measuring the concentration of hexavalent chromium in the soil;

[0073] Collect and filter the soil, place the soil sample in the leaching equipment for high-concentration heavy metal-contaminated soil at a room temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com