Continuous carbon fiber reinforced PEKK prepreg production process and equipment

A production process and production equipment technology, applied in the field of continuous carbon fiber reinforced PEKK prepreg production process and equipment, can solve the problem of inability to achieve continuous carbon fiber reinforced PEKK prepreg industrialized production, etc. The effect of improving the wetting ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

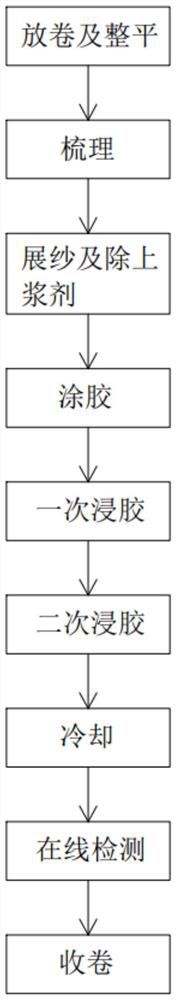

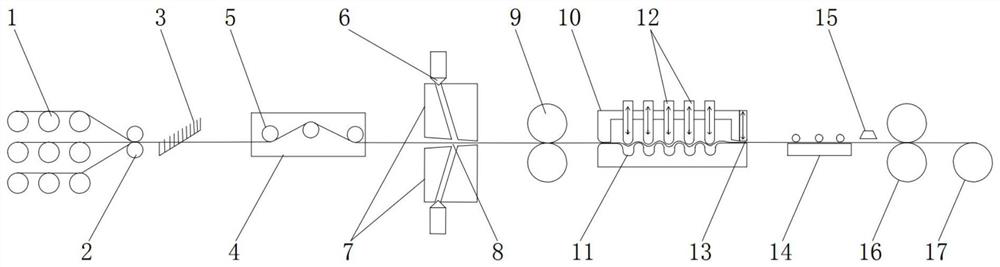

[0047] like figure 1 As shown, the invention discloses a continuous carbon fiber reinforced PEKK prepreg production process, comprising the following steps:

[0048] 1. Unwinding and leveling: the carbon fiber is led out from the creel 1, and after being tensioned by the guide roller group, the carbon fiber tow is gathered on the same plane;

[0049] 2. Carding: the carbon fiber tow is carded by the grate 3 and distributed evenly in the width direction;

[0050] 3. Yarn spreading and sizing agent removal: send the carbon fiber tow into the high-temperature oven 4, bake and remove the carbon fiber, and at the same time spread the carbon fiber tow to the required width and distribute them evenly through the spreading roller group in the high-temperature oven 4;

[0051] Four, gluing: the carbon fiber passes through the wedge-shaped gap 8 where the cross-sectional area between the upper gluing die and the lower gluing die gradually decreases. At this time, two sets of extruders,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com